- When new equipment is installed and when equipment is changed

- When there is new work or a change in work

- For work involving the handling of chemical substances

Health and Productivity Management and Occupational Safety and Health

Practicing Health and Productivity Management

Mitsubishi Electric implements health and productivity management with the aim of building an environment where employees can maintain good health both mentally and physically and thrive in their work. This effort is the foundation for a work environment that enables varied and versatile human capital to participate actively.

We have issued the Mitsubishi Electric Group Health and Productivity Management Declaration to clarify our policy for the entire organization. We are also integrating health and productivity management into various human resources measures and taking comprehensive measures to increase well-being. Moreover, under “MHP ‘Lively and Exciting Action,’” a project to promote health through cooperation between the company, the labor union, and the health insurance society, we have assigned an “MHP implementation leader” at each site and we are working on various activities to promote health, employing proactive implementation of activities not only from the top down but also from the bottom up.

We are also pursuing Group-wide certification under the KENKO Investment for Health (KHI) Outstanding Organization recognition program, which certifies enterprises that are outstanding in health and productivity management. This will increase the profile of our efforts and help enhance the corporate value of the entire Group.

Group-Wide Health Promotion Activities (MHP)

For two decades beginning in fiscal 2003, Mitsubishi Electric and its associated companies in Japan carried out the Mitsubishi Electric Group Health Plan 21 (MHP21) initiative—a collaborative health promotion program involving three parties: the company, the labor union, and the health insurance society. Targeting approximately 100,000 employees and their families, the initiative aimed to encourage early lifestyle improvements, prevent lifestyle-related diseases, and enhance quality of life (QOL), while realizing a health-oriented company.

In fiscal 2023, MHP21 was renamed the “Mitsubishi Electric Group Health Management Plan” and another five-year activity has started as “MHP ‘Lively and Exciting Action.’” Under the activity principle, “We promote fitness activities for each one of us to be excited to spend time in a lively way,” we are developing activities with the ultimate goal of achieving a subjective feeling of liveliness and excitement; that is, improved health satisfaction among each and every employee as well as their family members.

Specifically, we have set “good appetite,” “good sleep” and “good bowel movements” as three indexes to represent the daily level of health satisfaction (degree of liveliness and excitement) regarding the mental and physical health among each and every one of us, for the purpose of assessing the degree of achievement of the activity principle and objective. In addition, we have set “diet,” “exercise,” “smoking,” “care for the teeth,” “sleep” and “drinking” as six indexes for lifestyle habits. We utilize these indexes in a system that is designed to visualize each person’s health condition using ICT and other technologies, and that sets targets to encourage changes in behavior according to individual lifestyle habits. In this way, we have been promoting activities that lead to improved health satisfaction.

Our associated companies overseas are likewise taking initiatives to maintain and promote health among their employees, in consideration of the health situation in their respective countries.

MHP “Lively and Exciting Action” activity goals and achievements <Health satisfaction>

| Target item | Target value (by FY2027) | FY2025 result | |

|---|---|---|---|

| Good appetite | Percentage of people who have an appetite and enjoy their meals | 90.0% or more | 89.1% |

| Good sleep | Percentage of people sleeping comfortably and soundly | 80.0% or more | 56.4% |

| Good bowel movements | Percentage of people with good bowel movements that leave them feeling comfortable | 80.0% or more | 65.8% |

Addressing Women’s Health Issues

We regard women’s health issues as a vital matter directly related to full participation of human capital and organizational revitalization, and we work to increase health literacy regardless of gender or generation. Recently, we have held seminars featuring external lecturers on the perspectives of menstruation and infertility treatment. Information was provided on the available systems, and we received comments from many employees that they deepened their understanding and other such feedback.

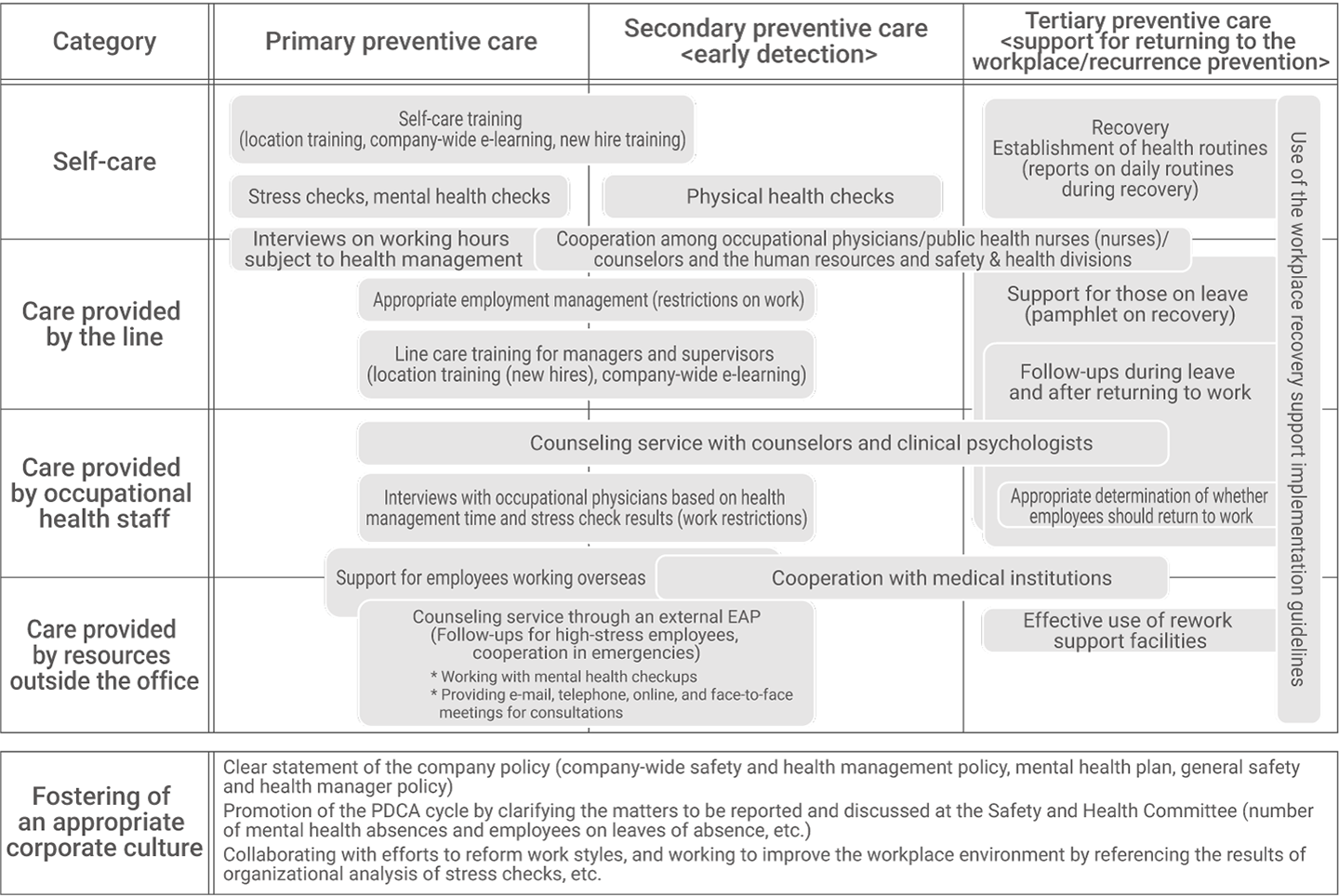

Promoting Mental Health Care

Mental health care is a top priority for health management in the Mitsubishi Electric Group. By establishing a counseling program that includes an industrial physician and/or counselor and other such initiatives, active efforts are made to help employees cope with everyday worries related to work and family and other emotional issues.

Through conventional telephone and e-mail counseling and a newly introduced face-to-face counseling program as well as an online counseling program provided by an employee assistance program (EAP),* which covers associated companies in Japan as well, we have actively worked on the primary prevention of employee mental health disorders.

In addition to checking issues related to mental health and formulating a Mental Health Development Plan, the Office Safety and Health Committee (Committee to Promote Mental Health) serves as a forum for collaboration among employees in charge of developing office policies and conducting measures. By disclosing through the Committee information such as the presence or absence of employees who had an injury/sick leave or absences due to mental health, the status of implementation of measures to ensure health and welfare (the number of people eligible for long-term counseling, etc.), and the plans for and results of mental health-related training programs, continuous improvement activities are promoted.

With regard to a stress check system in line with legislation, efforts are being made to improve the workplace climate of organizations with issues in light of the results of organizational analysis.

Furthermore, by conducting stress checks and appointing dedicated counselors in the Mitsubishi Electric Head Office, focused care is also provided to employees posted outside of Japan, where working and living environments largely differ from Japan.

In terms of education, line-care and self-care training are repeatedly implemented through lectures, to provide sessions on mental health and strengthen responses to mental health among managers and employees, especially for mental health. As a common feature of the Group, Mitsubishi Electric and its associated companies in Japan also provide safety and health education based on an internal e-learning system, which has been instrumental in promoting greater understanding of mental healthcare (line-care, self-care) to more than 100,000 employees, managers, and supervisors every year.

- Employee assistance program (EAP) is a program that provides support to employees, by providing a wide range of counseling covering physical health, relationships with family and colleagues, as well as mental health.

Mental health initiatives (Mitsubishi Electric)

Mental health initiatives (Mitsubishi Electric)

Occupational Safety and Health

Basic Policy

The Mitsubishi Electric Group promotes safety and health activities across the entire Group under the strong leadership of the top management.

Adhering to the basic policy of prioritizing the safety and health of our employees above all else, the Group aims to achieve the following two goals.

- Establish a culture that places top priority on safety and health in all social and business environments based on the understanding that health and safety management form the foundation of business management.

- Establish health and productivity management and create a workplace environment that allows everyone to maintain good health both mentally and physically and thrive in work as one of our core management policies for increasing employee engagement.

Based on these policies, Mitsubishi Electric has formulated a company-wide Safety and Health Five-Year Plan and promotes specific activities each fiscal year. Our associated companies in and outside of Japan, along with relevant partner companies, engage in health and safety management activities in line with relevant national laws and regulations, and company-specific issues, guided by a company-wide safety and health management policy.

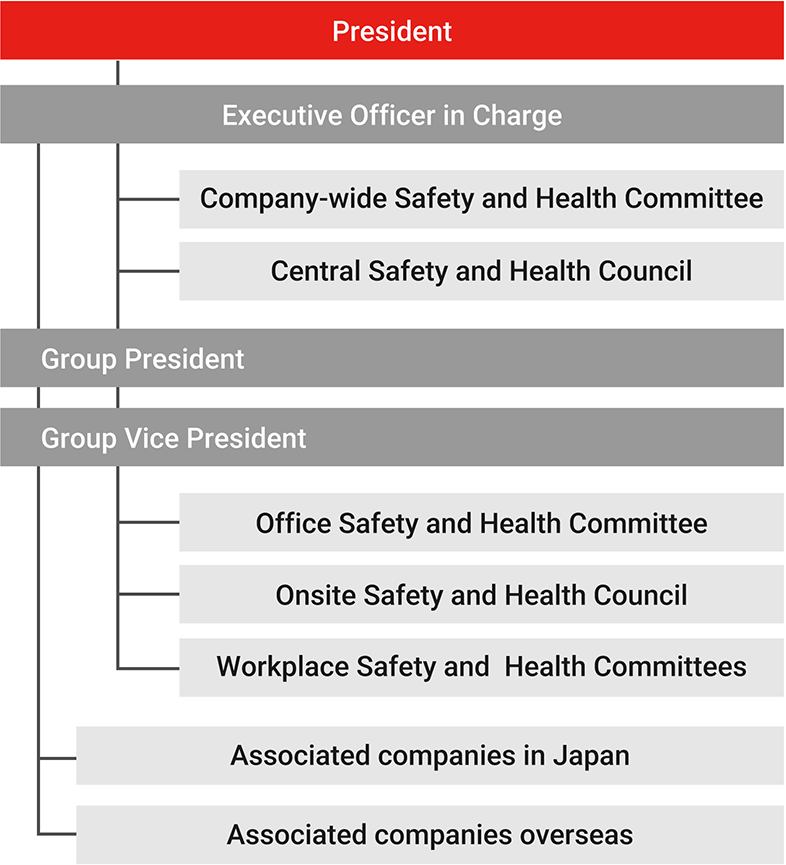

Promotional Framework

Mitsubishi Electric Group safety and health management framework

The Mitsubishi Electric Group and its associated companies in and outside of Japan cooperate in exchanging information about safety and health, engage in education activities, and implement various measures. Communication is also held with employees through meetings with labor unions and the Safety and Health Committee, and labor management efforts are made to raise the level of safety and health.

Occupational Health and Safety Management System

In fiscal 2010, Mitsubishi Electric introduced the Occupational Health and Safety Management System (OHSMS). Under the program, each office runs PDCA cycles for safety and health activities by implementing internal audits based on the Mitsubishi Electric Group’s requirements for safety and health management on foundation management and items to be individually managed. These requirements range from the development of policy and management frameworks in each office governed by a general safety and health manager (assumed by Group Vice President) to the implementation of risk assessment and other accident prevention activities through education to improve employee awareness of safety and health management. The goal is to raise the occupational health and safety management level of the company as a whole. Some business sites and associated companies in and outside of Japan have obtained external ISO45001 certification.

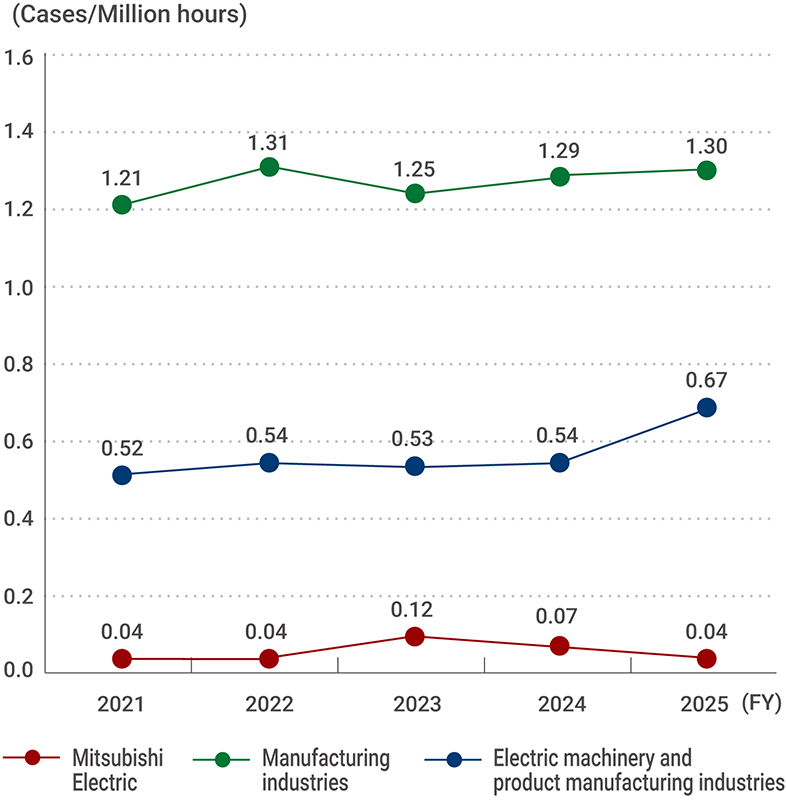

As a result of these initiatives, we have achieved one of the lowest frequency rates and severity rates of industrial accidents (number of people killed or injured in a fatal accident or an accident that requires time off from work per 1 million hours of work, and number of working days lost per 1,000 hours) in the industry.

Unfortunately, two fatal accidents occurred at Mitsubishi Electric Group’s overseas sites in fiscal 2025. To address this, we are working to identify risks and implement countermeasures specifically for maintenance and inspection operations, while strengthening our integrated safety management system. Although the Group’s overall accident incidence rate declined in fiscal 2025 compared to the previous fiscal year, we remain committed to achieving our fiscal 2026 targets by developing action plans and reinforcing our efforts.

Risk management

Mitsubishi Electric Group identifies hazards through risk assessment and implements risk reduction measures in the following cases.

If an industrial accident occurs, safety measures are immediately taken by the department where the accident occurred. At the same time, efforts are made to prevent similar accidents by conducting safety management status inspections and sharing countermeasures within the Mitsubishi Electric Group developed through case reports of disasters.

Frequency of labor accidents (Number of accidents requiring leave, per million hours)

Frequency of labor accidents (Number of accidents requiring leave, per million hours)

* This graph shows annual aggregated values.

Thorough Safety and Health Education

The Mitsubishi Electric Group implements safety and health education that matches its business characteristics and social environment, including job-level specific trainings and job specific programs, in addition to education programs as stipulated by law. We also provide health and safety education materials to relevant partner companies.

As a common feature of the Group, Mitsubishi Electric and its associated companies in Japan also provide safety and health education based on an internal e-learning system, which has been instrumental in promoting greater understanding of the principles and concept of safety and health to more than 100,000 employees, managers, and supervisors every year.

Furthermore, to strengthen experiential risk simulation training for employees, we have established facilities such as Safety Rooms. These business sites have been working to increase all employees’ hazard awareness by upgrading the simulation machine, introducing a virtual reality (VR) simulator, developing and providing education to instructors, and establishing an education system.

Safety Room (Kobe Works and Energy Systems Center)

Safety Room (Kobe Works and Energy Systems Center)