Quality

Basic Policy and Management

Basic Policy

Based on its Purpose, “We, the Mitsubishi Electric Group, will contribute to the realization of a vibrant and sustainable society through continuous technological innovation and ceaseless creativity,” the Mitsubishi Electric Group constantly strives to increase customer satisfaction in all aspects of its business, from the production of high-quality, easy-to-use products to after-purchase support, response to major issues, and product disposal.

Basic Philosophy on Quality

The Mitsubishi Electric Group is working to establish systems and environments that inherently eliminate the need for improper quality control practices, based on the following revised Basic Philosophy on Quality—updated to reflect employee feedback.

- We offer the quality that ensures customer satisfaction.

- We provide products and services with quality as our top priority.

- We each play a self-leading role for creating better quality.

Management

Mitsubishi Electric has established a company-wide framework for quality assurance and improvement activities. To promote and strengthen Quality Assurance Reforms, the Corporate Quality Assurance Reengineering Group—led by the Chief Quality Officer (CQO)—is implementing shared initiatives across the organization. The Corporate Quality Assurance Reengineering Group has a Quality Assurance & Management Department at each manufacturing base, which assumes the function for checking, including shipping authority, as well as a contact point for consultation on issues in the field.

Quality Improvement Activities

The Mitsubishi Electric Group promotes quality improvement activities in all business processes related to products and services to improve quality, safety, and reliability while promoting human capital development.

With regard to development and design in particular, we strive to develop human capital who are capable of assessing each country’s laws and standards, customer requests, and basic product functions, as well as executing and driving designs that ensure safety, reliability, and stability of functions. These human capital improve our development and design quality by ensuring, alongside other efforts, all parties involved are familiar with the elemental technology guidelines necessary for ensuring quality.

As for procured products, we have been working to improve quality in collaboration with our suppliers, who are important partners of the Mitsubishi Electric Group, by asking them to understand our policy that gives top priority to quality.

With regard to product defects, we have also built a database of failure cases that have occurred in the Mitsubishi Electric Group. We use this database to build quality into products to prevent defect recurrence.

Driving Quality Assurance Reforms

Through engineering process reforms, we are rebuilding our organizational capacity to deliver technically sound explanations—establishing systems and environments that inherently eliminate the need for improper quality control practices.

Rebuilding Deterrence Functions

We continue to conduct quality audits across Group sites, while also fostering talent in this area by offering tiered training programs on quality auditing at each location.

Addressing Technical Capabilities and Resource Challenges

Through investments in IT and digitalization, approximately 80% of inspection equipment used in final product testing for mass production has now been digitized.

Reinstilling Quality Compliance Awareness

On “Company-wide Quality Day,” we shared a message from the President underscoring the importance of keeping the memory of past failures alive. We also presented a video featuring interviews with employees who experienced past quality compliance issues. We also launched a rotating exhibit of related physical artifacts across all sites, with plans to establish a permanent exhibit in FY2026.

Enhancing Manufacturing Management Environments

To optimize resource allocation, we are visualizing workload levels in design and quality control operations at model workplaces across all manufacturing sites. In parallel, “factory health checks” are helping visualize manufacturing environments and share best practices across locations, supporting ongoing improvement efforts.

Advancing Front-Loaded Design Practices

Manufacturing sites are accumulating successful experiences with Quick DR—a design review method focused on functional changes and modifications. These successes will serve as the basis for company-wide rollout.

User-Friendly Products

Basic Policy

The Mitsubishi Electric Group has established the philosophy of “creating user-friendly products and comfortable living environments for many people” as the foundation of its universal design development. To achieve true user-friendliness and comfortable living, we are committed to providing products and living environments that offer a high level of satisfaction to as many people as possible.

Mitsubishi Electric Group's Initiatives in Universal Design

We have applied the concept of universal design (UD) to home appliances such as air conditioners and refrigerators, as well as to public equipment such as elevators, by considering the needs of all users. This approach is continuing to evolve.

“UD Guidelines” for ease of use for many people

The UD Guidelines are standards applied to a wide range of product development to ensure usability of our products by all users, including children, the elderly and those with disabilities. These guidelines summarize considerations for changes in human characteristics due to aging and disabilities, and are structured around four perspectives: "cognition," "identification," "physical," and "safety and usability."

UD-Checker, the Universal Design Evaluation System

UD-Checker is Mitsubishi Electric’s original tool that can be used by both designers and engineers to evaluate universal design qualities.

This tool shows four perspectives: "cognition," "identification," "physical," and "safety and usability," indicating specific design aspects for development and improving the efficiency of product development. The UD-Checker is used on a wide variety of Mitsubishi Electric Group products from home appliances and public equipment to industrial equipment.

The UD-Checker’s Four Evaluation Criteria

Application to Home Appliances

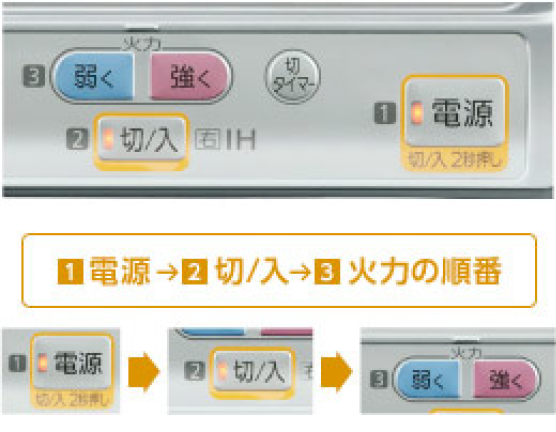

To ensure that customers can use our home appliances with peace of mind, we have been actively promoting the application of Universal Design. For instance, we have applied the Universal Design Guidelines to the IH cooking heater.

Large characters & numerical indicators

“RakuRaku-IH” Cooking Heater CS-G221AKS

Large characters & numerical indicators

Features

Characters are approximately 1.8 times the size of our conventional system. (Compared with Mitsubishi Electric's conventional model G38MS)

Can be operated simply by pressing buttons in order of numbers displayed.

Application to the Industrial Sector

Even in the industrial sector, where there is a high level of specialization and a relative lack of diversity in terms of operators who handle equipment, the labor environment is changing. Examples of this transformation include the aging of workers, and more foreign and inexperienced workers—changes that have increased the need for universal design. At the Mitsubishi Electric Group, we are applying the concept of universal design to our industrial products, such as factory automation equipment and electric power devices, as well as to the installation and maintenance of equipment on factory floors.

Creating Easy-to-Understand Instruction Manuals

Under a campaign to provide first-rate instruction manuals, the Mitsubishi Electric Group is directing its efforts to create easy-to-read and easy-to-understand instruction manuals to ensure the safe and comfortable use of our products. Forming the basis of this effort is Mitsubishi Electric’s original “Guidelines for the Creation of Instruction Manuals for Home Appliances—Instructions.” To raise the quality level of instruction manuals, this handbook is distributed to all associated companies in Japan that handle home appliances.

Award Received

In FY2025, we won the following awards at the IAUD International Design Awards organized by the International Association for Universal Design (IAUD). All of the winning products below received awards due to the exploration of the needs of consumers and users and the design of functions and services to realize usability that meets those needs.

- Silver Award — "MeAMOR" gently protects families living apart from each other with home appliances

- Bronze Award — A Smart Factory Concept that is Friendly to All People: A concept that facilitates collaboration between people inside and outside the factory to share services and equipment.

Mitsubishi Electric will continue creating products and services that leverage the extensive range of its technologies to solve the problems of users.

"MeAMOR" gently protects families living apart from each other with home appliances

"MeAMOR" gently protects families living apart from each other with home appliances

A Smart Factory Concept that is Friendly to All People

A Smart Factory Concept that is Friendly to All People

Improving Customer Satisfaction

Basic Policy

The Mitsubishi Electric Group has been committed to customer satisfaction since its founding. Inheriting this spirit, we collect feedback from our customers through customer satisfaction surveys as appropriate to the characteristics of each business operation and incorporate customer opinions into product development, marketing strategies, and services.

We also strive to maintain customer satisfaction by strengthening our repair/service systems, providing effective staff training, and expanding access to information via our websites.

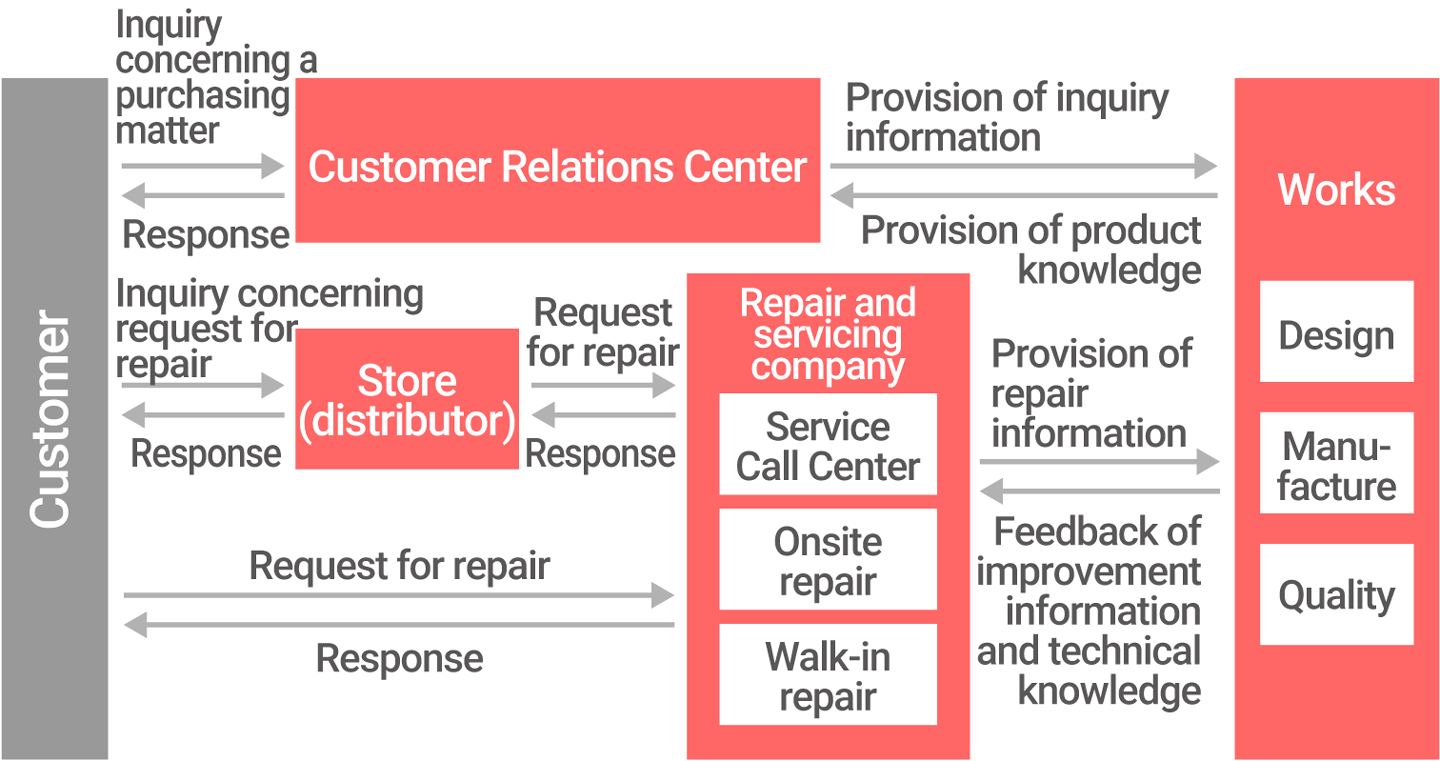

Flow of responses to customer inquiries (Mitsubishi Electric)

Flow of responses to customer inquiries (Mitsubishi Electric)

CS Activities by the Home Appliances Group (in Japan)

The Living Environment & Digital Media Equipment Group handles matters related to home appliances and carries out customer satisfaction (CS) improvement activities. These activities are aimed at ensuring that Mitsubishi Electric products are available to as many people as possible and that customers across the country can use the product they purchase with confidence. We value contact with customers and retailers, offering guidance on purchasing decisions, product usage, and after-sales service. We continuously strive to incorporate feedback from these interactions into future product development, sales, and service improvements.

System of Reviewing Customers’ Comments

The content and results of consultations and repair requests from customers and the details of technical inquiries are sent as feedback to the manufacturing works. They are used to improve both products under production and in development, and to provide repair information to distributors.

The Customer Relations Center compiles a database of customer feedback and periodically sends the results of trend analysis to works, sales companies, and research institutes. Works and sales companies strive to improve current products and simplify instruction manuals, while research institutes use the information to improve products under development. At the same time, regular liaison meetings are held between works and the Customer Relations Center to address issues and improve information collection.

Shizuoka Works has created opportunities for engineers to hear feedback from customers directly in order to improve the quality of room air conditioners "Kirigamine." When quality problems arise, engineers visit the customer to check on the usage environment and provide feedback for product development. Such feedback is used to improve product design and control specifications. We have also reflected feedback from customers in our efforts to improve product quality with respect to perceived temperature control and the noise of outdoor units. We will continue to improve our products by using valuable customer feedback.

CS Activities by the Building Systems Group (in Japan)

The Building Systems Group handles elevators and escalators that provide vertical transportation within buildings and building management systems. By ensuring their safety and security and continuously delivering comfortable means of transportation and living spaces as indispensable social infrastructures on a global scale, we contribute to making society even more vibrant and sustainable.

24-Hour, 365-Day Safety Hotline

Information center

The Building Systems Group operates eight Information Centers in Japan that serve as a 24-hour, 365-day Safety Hotline for customers, providing immediate support in emergencies. These centers continuously monitor the operational status of building facilities remotely. When an abnormal signal is detected, the system identifies and dispatches the most suitable engineer—selected from a pool of approximately 6,000—based on proximity and ability to respond quickly and accurately. The selected engineer receives building information and past service records, while urgent parts are arranged as needed. This ensures the swift restoration of facility functions.

Moreover, by monitoring changes in data on the operational status of elevators and air-conditioning facilities, information centers strive to detect and address abnormalities before they develop into malfunctions and prevent problems from occurring.

Mitsubishi Elevator and Escalator Safety Campaign

Mitsubishi Elevator and Escalator Safety Campaign

Elevators and escalators are used to transport a large number of persons, so a high level of safety is imperative, and they are thus equipped with various safety devices and functions. At the same time, regular maintenance and inspection and correct use are necessary to ensure safe operation.

The Mitsubishi Electric Group conducts the Mitsubishi Elevator and Escalator Safety Campaign, which includes two types of briefing sessions: User Briefings to raise awareness among elevator and escalator users about proper usage, and Facility Manager Briefings to provide building owners and facility managers with guidance on daily management practices and emergency response procedures. These sessions have been attended by more than 300,000 people to date and will continue to be held as one of the important safety activities of the Mitsubishi Electric Group.

Topics

Inazawa Building Systems Works SOLAÉ showroom

The showroom attached to the 173-meter-tall SOLAÉ elevator testing tower receives visitors from facility owners, design offices, and construction companies—as well as children from the local community—and having them see, feel, and experience actual products and technologies related to elevators, escalators, and building management systems from Mitsubishi Electric that are fundamental to building operation, the showroom communicates the safety and security of Mitsubishi Electric’s products.

The elevator and escalator zone introduces visitors to the history of elevators and escalators, and, using actual elevator and escalator units, provides a survey of subjects ranging from their basic structure to the latest products and technologies that ensure their safety, security and comfort. Visitors can also experience the “function to connect with people” that improves operating efficiency and comfort as well as the “function to connect with the building” for integrating elevators with other building facilities. The building management system zone allows visitors to experience technologies including the latest building management and security systems.

SOLAÉ elevator testing tower

SOLAÉ elevator testing tower

SOLAÉ showroom

SOLAÉ showroom

Product Safety-Related Principles

Basic Policy

Based on the Purpose and Our Values, the Mitsubishi Electric Group promotes product safety initiatives under its Product Safety-Related Principles.

With regard to consumer products particularly, Mitsubishi Electric is committed to preventing serious hazards that could result in death, injury, fire, or other damage, by subjecting all products to a quantitative risk assessment at the development stage, while also designing and developing products in consideration of their end-of-life management (to ensure safety even at the stage where products are prone to break or be discarded).

Responding to Product-Related Issues

Basic Policy

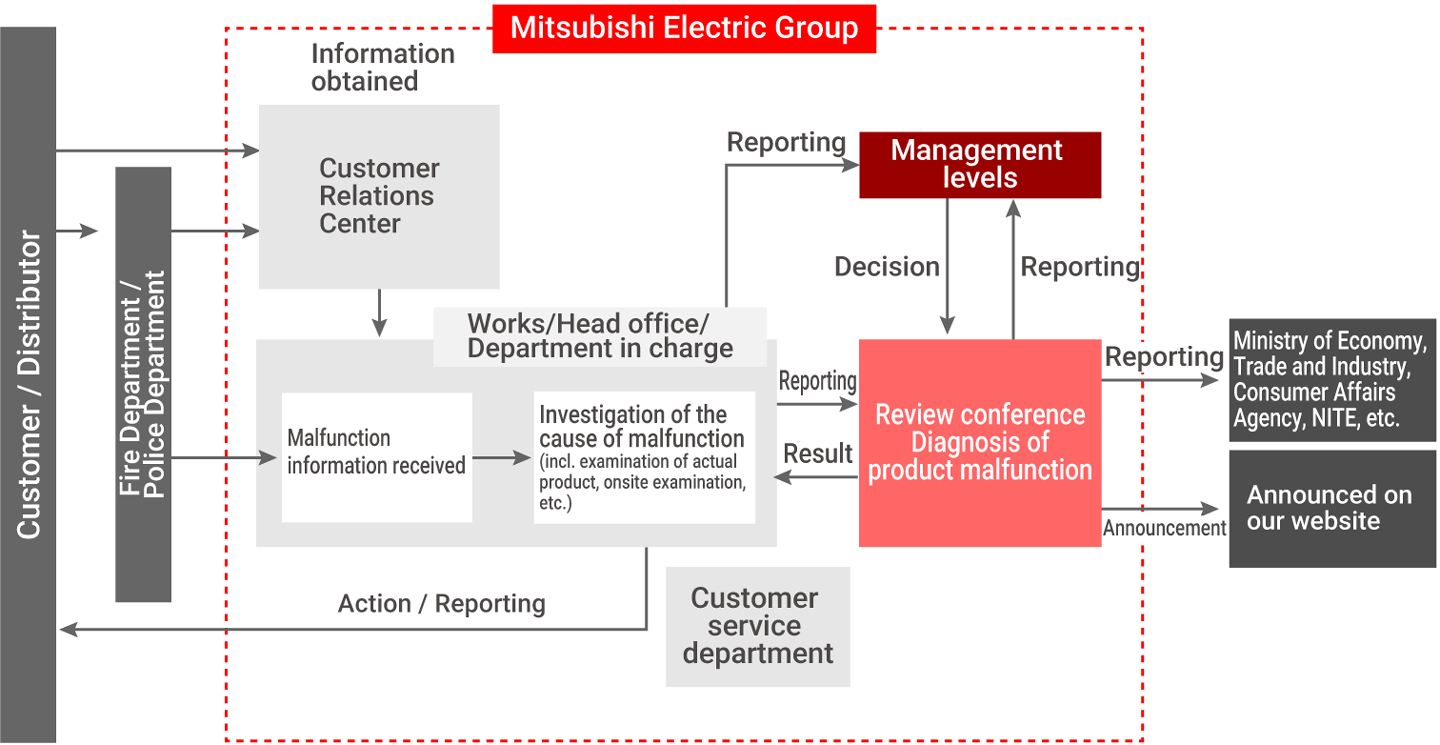

If we receive any report of a major issue occurring in a product that we have sold, we have a system in place that includes the top management to ensure quick and accurate decisions on the steps and measures to take, so that we can take proper action while always placing top priority on not inconveniencing our customers. In addition, we will share information on major issues that occurred with regard to products across the entire Group promptly to strengthen our ability to respond to such issues.

For recalls in particular, we work on an ongoing basis to ensure that all the relevant products that were sold are returned and repaired, and apply these efforts to a wide array of sales channels.

Reporting Major Product Issues

A detailed list of information pertaining to important product-related and quality issues is posted on Mitsubishi Electric’s Japanese-language official website.

Accident Reporting Based on the Consumer Product Safety Act

In Japan, we promptly release appropriate information on issues in consumer products, which directly and deeply affect consumers.

Detailed information on our compliance with Japan’s revised Consumer Product Safety Act, which went into effect in May 2007, is available on Mitsubishi Electric’s Japanese-language official website.

Flow of responses to accidents (Mitsubishi Electric Group)

Flow of responses to accidents (Mitsubishi Electric Group)