CNC M800/M80 Series

Lineup

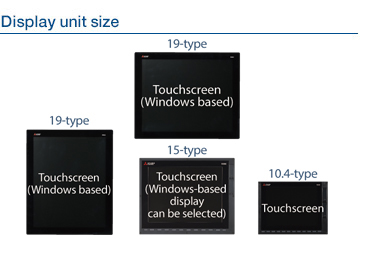

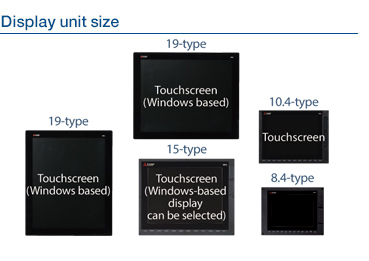

M800W

Premium CNC provides expandability and flexibility

- Separated type, a control unit separated from display

- Windows-based display is included in the lineup, which provides excellent expandability

- Four expansion slots are provided as standard specifications, allowing for expansion using option card slot

M800S

High-grade CNC well suited to high-speed high-accuracy machining and multi-axis multi-part system control

- Panel-in type, a control unit with integrated display

- Multi-CPU architecture allows for high performance and high functional graphics

- Windows-less display provides easy operability

M80W

Standard CNC with expandability and flexibility

- Separated type, a control unit separated from display

- Windows-based display is included in the lineup, which provides excellent expandability

- Packaged type for selecting a machine type easily

- Two expansion slots are provided as standard specifications, allowing for expansion using option cards slot

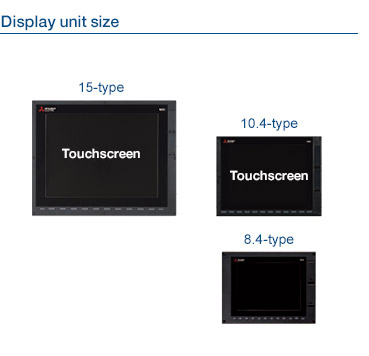

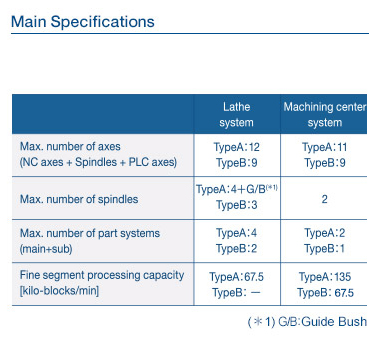

M80

Standard CNC provides high productivity and easy operability

- Panel-in type, a control unit with integrated display

- Provided in package (TypeA/TypeB) for easier selection

- Windows-less display provides easy operability

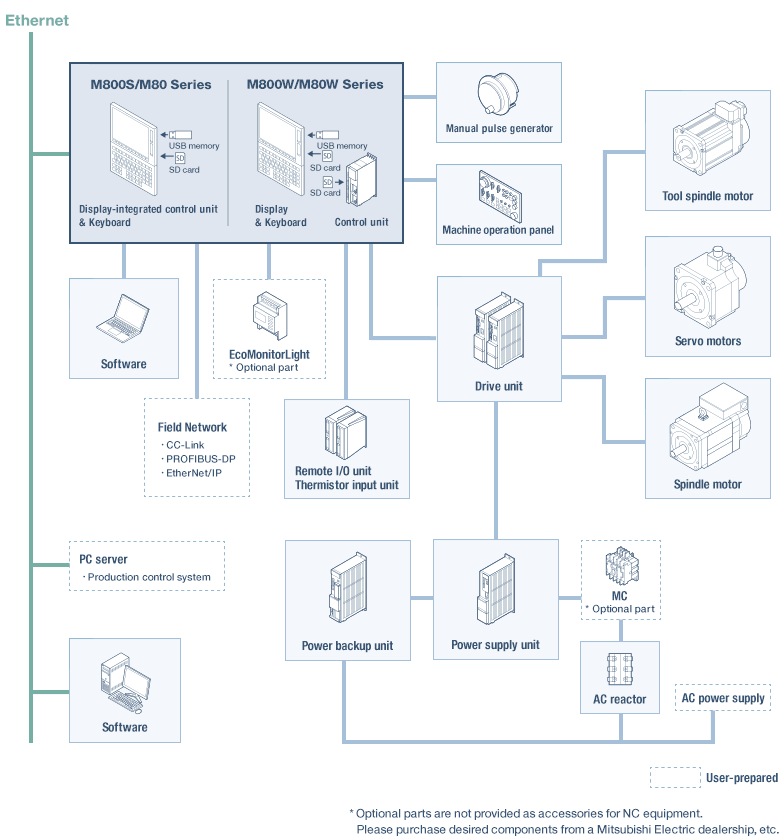

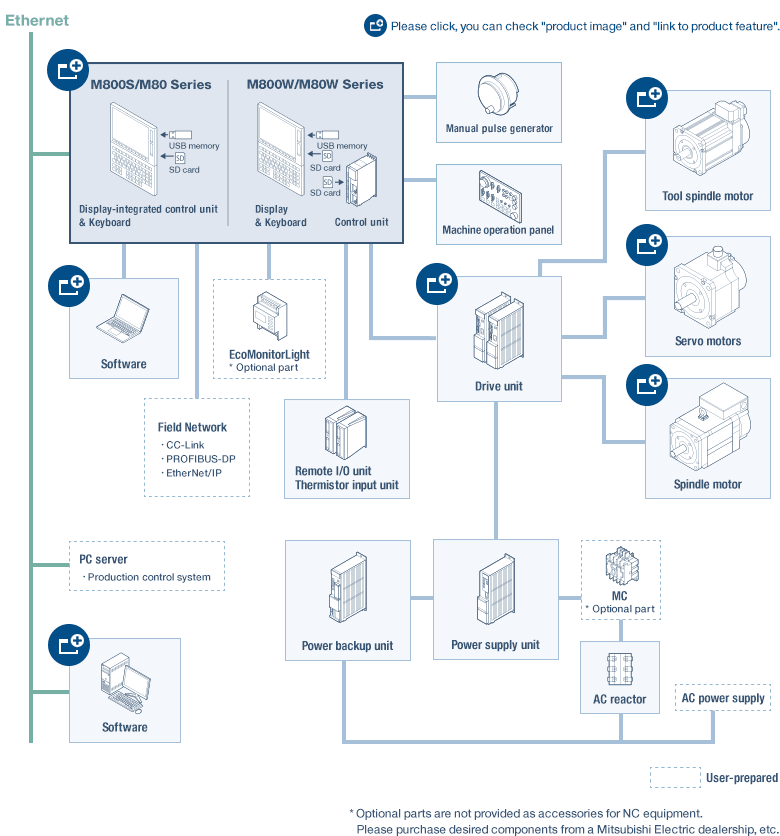

System Configurations

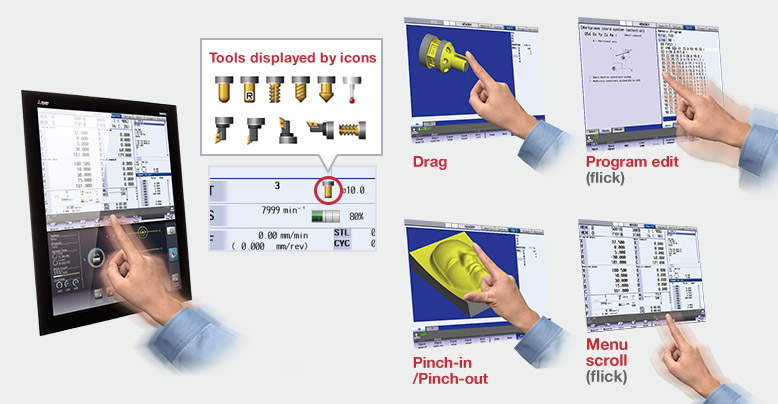

Usability

A TOUCH PANEL THAT OFFERS REVOLUTIONARY USABILITY

- Touch gestures make for visceral, comfortable usability

- Advanced universal design with a focus on ease of use

- Icons and animations create a high level of visibility

- Screens can be customized, so move menus around and select the indication method

2-SCREEN SETUP WITH 19-INCH VERTICAL DISPLAYS

- Check a machine operating status at a glance on the home screen

- Smartphone-like usability eliminates the need to use a manual

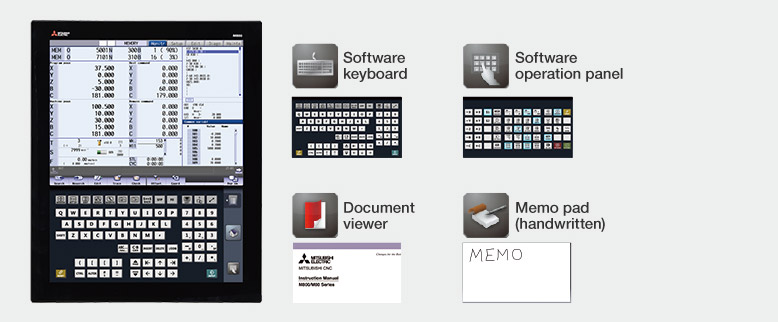

- Software keyboard, control panel, user manual reference, and notepad for handwriting features come standard

- Customize applications by adding, deleting, or rearranging them

CNC-dedicated CPU

- High-speed processing performance that far surpasses conventional limitations

- Superior machining program processing capacity for high-productivity

- High level PLC processing capacity for high-speed

- processing of large-scale ladder programs

- Fewer parts used means fewer potential breakdown

- factors and higher product quality

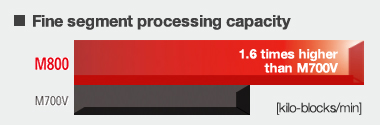

High capability in program processing enables a shorter cycle time.

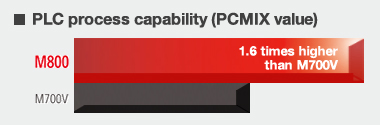

High processing capability of the PLC enables large-scale ladder logic to be processed at high speed.

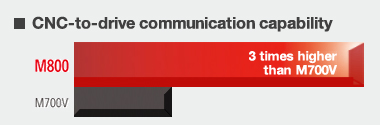

Optical communication speed between CNC and drive has been increased. This improves the system responsiveness, leading to more accurate machining.

Lathe System

ENHANCED LATHE SYSTEM

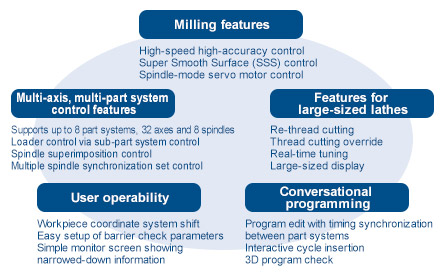

Milling features and multi-axis, multi-part system control features have been significantly improved.

Progress has been made in operability, enabling operators to implement ever more complex machining in an easy and efficient manner.

Implement ever more complex machining in an easy and efficient manner

Milling features have been enhanced through high-speed high-accuracy control, SSS control and inclined surface machining command. Multi-axis, multi-part system control features have also been upgraded. A wide array of these features help ensure high productivity.

Significant progress has also been made in frequently used operation as well as programming, such as tool offset and workpiece coordinate system shift, which allows operators to easily implement ever more complex machining.

Machining Center System

ENHANCED MACHINING CENTER SYSTEM

SSS control has further evolved, realizing high-speed, high-accuracy, high-quality machining.

In addition, this CNC offers features that bring out the full potential of each axis and minimize non-cutting time, leading to higher productivity.

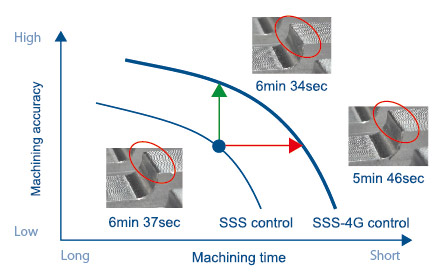

High-speed, high-accuracy, high-quality cutting through SSS-4G control

M800/M80 Series offers SSS 4th-generation (SSS-4G) control, enabling high-speed, high-accuracy, high-quality machining. SSS-4G control provides features that are effective in reducing tact time, including optimal acceleration/deceleration suited to each axis' characteristics. In addition, SSS-4G is capable of reducing machine vibration during high-speed cutting.

SSS-4G control allows for greater cutting accuracy in the same length of time, or shorter cutting time with the same degree of accuracy when compared to our previous models.

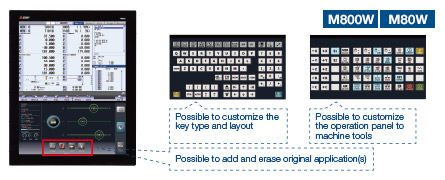

Customization Feature

UNIQUE CUSTOMIZATION

A high level of screen customization is attainable more easily in a shorter period of time.

Highly scalable hardware and advanced drawing application make it possible to increase the added value of machine tools.

M800W/M80W Series is equipped with a 19-type vertical display with a two-split multi-window screen.

Home application in the lower half can freely be customized.

19-type vertical display boosts the added value of machine tools

The display shows the standard CNC screen on the upper half, while offering the lower half (home application) to be freely customized. It is also possible to add some originality to machines to increase their added value. However, it is difficult to design the whole screen at the same time. This screen layout can satisfy such needs.

Combined with customers' ideas, the possibilities are infinite.

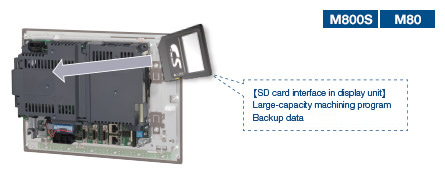

Additional SD memory card interface on backside of display.

An SD card can store large-capacity machining programs.

Support for large-capacity custom data using the SD memory on the back of display

The panel-in type CNC with integrated display has the SD card interface on the back of the display. By installing an SD memory card, large-capacity machining programs can be stored.

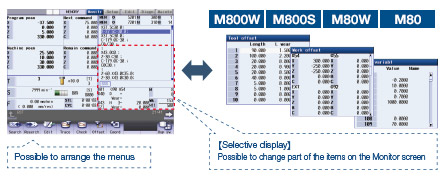

Standard screens can be customized using the selective display and rearranging menus.

Screens matching operators' preferences and needs enable even greater ease of use.

Customize the standard screens as per the preference of operators

Each operator has their own set of frequently used menus. This CNC allows operators to rearrange their menus and hide any unused ones so they can easily navigate to their desired screen. This CNC has a function called Selective Display, which enables partial customization of the Monitor screen. Selectable Display allows you to constantly display tool offsets, common variables, or a custom screen made by a machine builder.

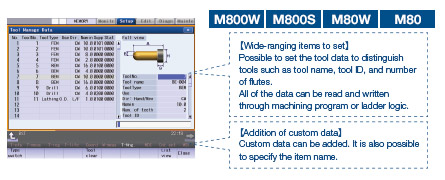

Tool-related information is collected and centrally managed on the Tool Management Screen.

Enhanced tool management screen

The CNC provides new tool management screen, where you can gather and manage tool-related information with greater convenience.

A wide range of setting items such as tool name and tool ID are readily available. You can read or write tool data or add custom data via ladder or machining program.