Solutions

Data Collection/Analysis

The Cycle for shop floor Improvement With Data Utilization

Improving productivity, quality, and energy efficiency by utilizing shop floor data to find the key to solving production issues and promoting improvements

Case15Conducting predictive maintenance on equipment by diagnosing vibration data

Diagnosis

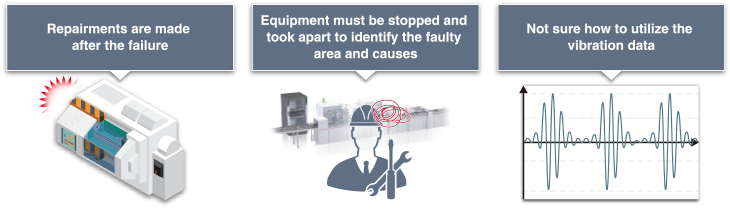

Issues

Solution

The equipment abnormalities can be detected by analyzing and diagnosing the vibration data.

Vibrations can be easily analyzed for predictive maintenance while keeping initial costs low

The e-F@ctory Starter Package includes sample projects for the MELSEC iQ-R Series and the GOT2000 Series.

This package enables general vibration analysis, including frequency analysis and vibration intensity monitoring of each frequency band, allowing it to be used for various equipment.

● Suitable equipment

Equipment where changes in vibration when abnormalities occur, such as glass cutting equipment or grinders.