Solutions

IoT Solutions for Machining Lines

Case.01Ensuring an easier way to perform remote monitoring of old machine tools

- Monitoring

- Individual equipment

- Overall line

Issues

Data collection from old machine tools is complicated, and the cost of implementation is likely to be high.

Solution

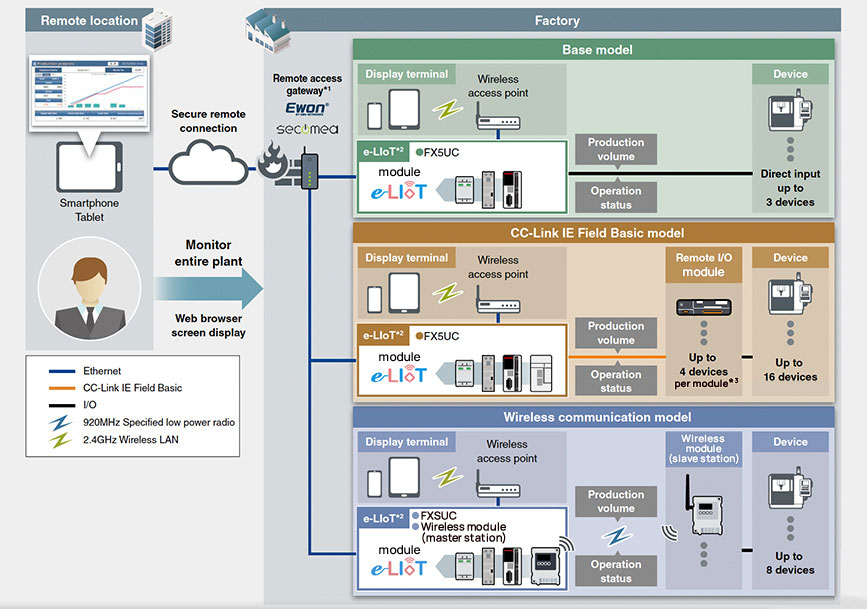

- The production monitoring package, e-LIoT, easily collects data from equipment and visualizes the production status on a web browser

- Build a secure remote access environment with Ewon/Secomea’s remote solution

- *1Operation has been confirmed for the Ewon Cosy Series and Secomea Sitemanager Series.

- *2e-LIoT is a production monitoring package that uses the iQ-F Series FX5UC to collect I/O and other data, and then visualizes such data on an web browser.

- *3Up to four devices can be connected per remote I/O module

Benefits

- Build a system for visualizing production progress and operation status in a short period of time

- Monitoring various statuses can be done easily using a smartphone or tablet, allowing users to make accurate decisions based on collected data