Solutions

IoT Solutions for Machining Lines

Case.03Supervising and managing everything from the entire factory and building to individual production lines, equipment and devices

- Monitoring

- Individual equipment

- Overall line

- Overall factory

- Multiple locations

Issues

It is difficult to manage the operations of numerous systems and equipment in the factory, and the overall optimization of the factory has not yet been achieved.

Solution

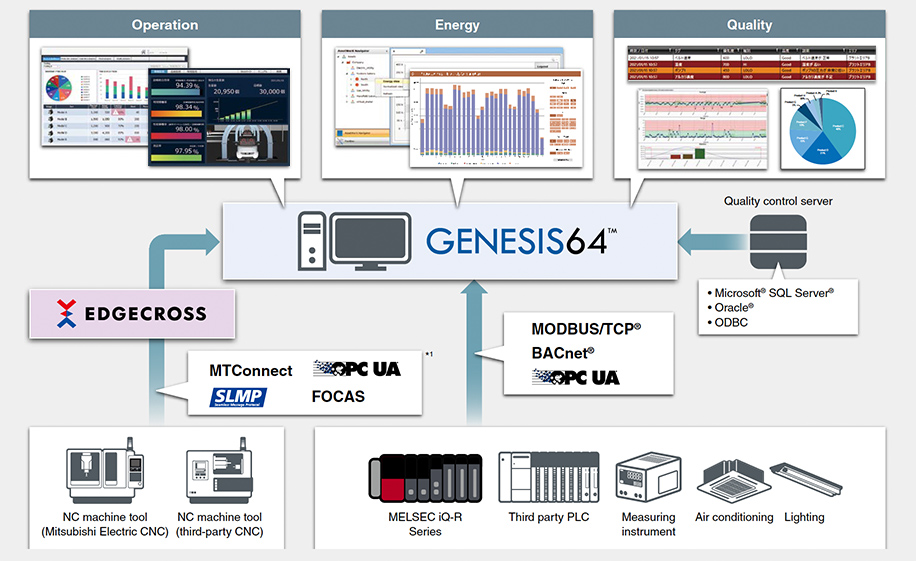

- Connect to various systems and devices to achieve visualization with the SCADA GENESIS64™

- This software supports industry-standard open protocols such as OPC UA, MODBUS® and BACnet®, as well as various general-purpose databases

- SCADA GENESIS64™ also provides a comprehensive range of analysis functions and means for visualizing operations

- *1By utilizing various Edgecross data collectors, it is possible to communicate between various devices over various networks.

Benefits

- Managing vast amounts of data centrally on the manufacturing shop floor makes it possible to improve production-related operations such as productivity, manufacturing quality and product quality, and energy efficiency