World roundup

Mitsubishi Electric Automation Korea

MECA competition: "Beyond automation, empowering people"

Published in December 2025

Part 2: Students’ Challenge — Designing and Building the Factory of the Future

Connecting reality and imagination through technology to assemble the future factory

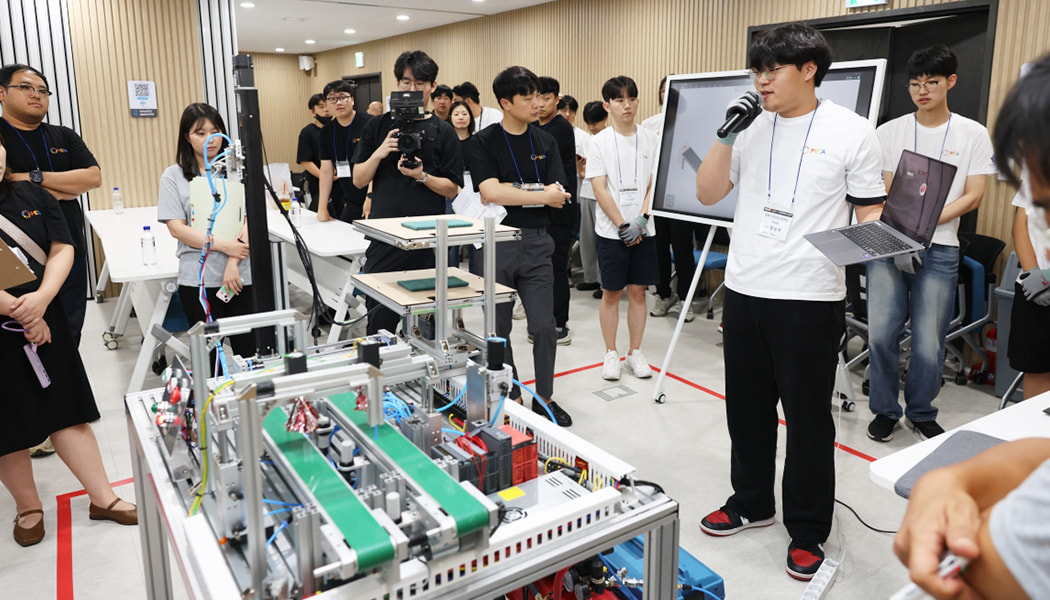

The presentation session at MECA KOREA CUP offered a showcase of applied technology. Ten teams presented their ideas and technical implementations, with participants ranging from high school students to graduate students.

The "KAI" team from Hanyang University implemented an automated assembly process using digital twin technology. They integrated AI cameras with collaborative robots to control robot movements based on the operator’s position and applied a reinforcement learning–based system to determine grasp positions, creating a system where humans and robots work together.

The "MCA" team from Dongyang Mirae University presented a smart management system to address security issues related to the handling of hazardous materials. The system, which integrates RFID-based access control, real-time simulation, 3D visualization, and CCTV monitoring, demonstrated a high level of technology readiness as a practical model for managing storage facilities.

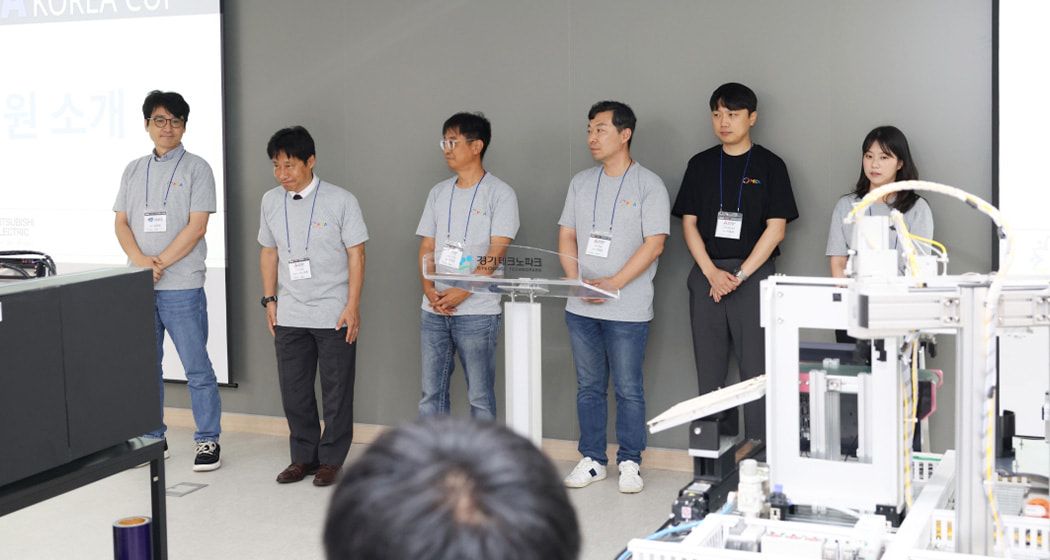

MECA Competition Judging Panel

The "No Errors" team from Gyeongbuk Machinery Technical High School selected "Automated PET Bottle Recycling" as their project theme. Their approach focused on minimizing user inconvenience due to label removal and bottle compression. Onlookers were impressed by how they addressed environmental issues using industrial automation.

The "No Errors" team from Gyeongbuk Machinery Technical High School presenting their project.

The "Elecsys" team from Yeungjin University developed an automated ball return system for golf putting. By utilizing conveyors, cylinders, HMIs, and SCADA software GENESIS™, they designed a solution accessible to elderly individuals and patients undergoing rehabilitation, highlighting how industrial automation technology can improve quality of life.

The "Elecsys" team from Yeungjin University presenting their project.

The "Winner" team, from Gyeongbuk Machinery Technical High School, developed an automated tray cleaning system. Driven by the goal of reducing the physical burden on cafeteria workers who manually clean over 1,000 trays each day, their idea evolved into a process design incorporating digital twin technology and an automated loading system. The team's presentation demonstrated both social sensitivity and technical execution.

The team from Seongnam Campus of Korea Polytechnic University, known as the “Supreme” team, developed an advanced port automation system, managing the project from design through to implementation. Their implementation combined multiple technologies, such as vision-based position recognition, vibration control, and real-time simulation through 3D Simulator MELSOFT Gemini and SCADA software GENESIS™, earning high praise from experts. Team leader Wooseok Baek, who presented the project, confidently stated, "A fully automated port system without human intervention is entirely possible."

The automated port container crane system presented by the "Supreme" team

The presentation session was more than just a showcase of technology; it was a testament to each team's journey. Throughout their implementation processes they encountered failures, made revisions, and faced practical challenges head-on. Some teams creatively constructed frames from discarded parts, while others innovatively designed equipment using 3D printers. Despite a few explanation videos not playing and some equipment glitches during their presentations, the teams maintained their smiles and optimism, saying, "We can do better next time."

By directly engaging with digital twin, SCADA, HMI, and robot control technologies, the students were able to connect these new tools to their everyday lives. Although the ten future factories they created are still be small and not yet perfect, they clearly demonstrated great potential and a deep understanding of real-world challenges. This alignment in their technological direction reflects a common purpose: to design automation that serves people.

Field interview "From wiring design to full digital twin implementation"

Seungwoo Ham, a student from Gyeongbuk Machinery Technical High School who participated in the “Winner” team said, "This competition was truly a practical learning experience."

Inspired by the idea of addressing the workforce shortage in cafeterias, they independently designed and fully implemented a smart cooking support system. Through the process of preparing for the competition, they acquired practical problem-solving skills that went beyond theory.

Ham said, "During the skills certification activities, we mostly programmed existing equipment, but this time, we independently designed and executed everything from wiring to assembling the cylinders." The process also included the use of digital twin software such as SCADA software GENESIS™ and 3D Simulator MELSOFT Gemini. "Gemini was an unfamiliar tool to us at first,” he shared, “but the training helped us become proficient with it."

Seungwoo Ham of the "Winner" team from Gyeongbuk Machinery Technical High School presenting a demonstration.

This competition was more than just about presenting a project. After advancing past the preliminary round, participants took part in a technical training program provided by Mitsubishi Electric. Over three days, they attended online and in-person lectures on software operation, visualization techniques, and simulation fundamentals. Any topics that were not fully covered were supplemented with materials from Mitsubishi Electric’s headquarters in Japan.

Ham commented, "We used to find implementing digital twin technology overwhelming, but then it suddenly started to make sense." Through this experience, he not only developed his technical skills but also strengthened his teamwork and confidence, and added, "I still vividly remember how thrilling it was to see the system we built actually working. We would like to keep taking on new challenges in this field."

Wonwoo Park, a student from Hanyang University, remarked, "This competition made me realize that knowing only robotics isn’t enough.

As a robotics student, he experienced the complexity of industrial automation by designing the communication structure between PLCs and robots himself. The project expanded beyond simple sequencing, evolving into a practical platform for implementing an integrated control system based on digital twin technology. In this context, his team, consisting of two undergraduate and two graduate students, designed a process that covered both robot control and PC logic.

"This made me realize for the first time that the PC plays a pivotal role in the process, not just as a simple control device," added Park.

Although the preparation period was short, Mitsubishi Electric’s training support offered a reliable foundation. They overcame technical challenges by making use of online lectures, real-time feedback via the open chat platform KakaoTalk, and online video materials.

Wonwoo Park, a student from Hanyang University

Park was also impressed by 3D Simulator MELSOFT Gemini and SCADA software GENESIS™, commenting, "Gemini is more specialized for practical industrial processes than existing simulators, and it's highly accessible since we can immediately use a variety of industrial robot assets."

With various equipment like Doosan robots already built in, there was no need to upload separate files to start simulations, and syncing with the PC was intuitive.

Reflecting on the experience, Park said, "People say manufacturing is in crisis, but we believe it remains competitive when talent and technology come together."

He further expressed his ambition to keep seeking technical solutions in the field of process automation and robotics integration. MECA, for him, was not just a skills competition but an opportunity to connect the essence of industry with technological evolution.

Special interview ① "The philosophy behind MECA by Mitsubishi Electric"

Watching the first-ever competition unfold, MEAK’s Tsukasa Yamaguchi emphasized that MECA is not just a skills competition, but a "talent development platform driven by social contribution" aimed at preparing the future of manufacturing.

Yamaguchi stated, "Since our products support factory automation, our social contribution is focused on nurturing talent." He emphasized that automation technology is essential in manufacturing dealing with a growing labor shortage.

However, he added, "Factories won't just operate by introducing machines," highlighting that nurturing talent for design and maintenance is an essential element of automation.

Tsukasa Yamaguchi, mentioned that MECA is a "talent development platform driven by social contribution” for the future of manufacturing.

Yamaguchi shared his thoughts on the first-ever competition being held in Korea, saying, "I wish it had started here sooner."

"Korea’s manufacturing technology is just as advanced as Japan's,” he added. “Since it's a bit late getting started, there’s an even greater reason to actively nurture talent."

This competition involved more than just Mitsubishi Electric. Public and research institutions such as the Human Resources Development Service of Korea and KETI SMIC also participated, making the competition a platform to explore technical education governance across the industry. Yamaguchi said that this sense of collaboration is the most meaningful aspect of MECA. He also presented a clear direction for the future.

"While this year's competition focused on integrating FA with software, we hope to expand into broader technological areas such as AI and big data analysis in the next competition," he started, emphasizing that MECA's themes will continue to evolve in line with technological advancements. Yamaguchi also mentioned the Global MECA finals, set to take place in Japan in September 2026.

He commented, "Bringing together the winning teams from around the world will provide a great opportunity to directly experience a variety of industrial structures and technological approaches," expressing his hope that it will inspire the Korean team to actively engage in the global technological exchange.

At the same time, he also highlighted the talent development within the corporation. Mitsubishi Electric dispatches its employees in Korea to its headquarters and factories in Japan for training every year. These programs, which range from three months to two years in duration, are systematically designed to enhance process understanding, skill development, and network building. He described it as a tradition that has lasted over 20 years and more than just simple training but a growth strategy for the entire organization.

In closing, he reflected on the students who participated in the competition, saying, "Watching their determination and focus, I saw the future of Korean industry. The MECA KOREA CUP has just begun, but it will surely carry on. We will continue to support them every step of the way."

Special interview ② "In the era of AI factories, people are the real key"

Byunghoon Song, Center Director of KETI SMIC, said, "As technology advances, the industry standards need to be redefined."

Byunghoon Song, the Center Director, described MECA as the only skills competition in Korea that simultaneously addresses the three pillars of automation, DX, and AI.

The center he leads serves as a pioneering hub for research into autonomous manufacturing, going beyond AI and automation. He emphasized that the MECA competition is "not just a simple competition but an experiment to set new standards in manufacturing." KETI SMIC is dedicated to researching smart factories and advanced technologies, with a recent focus on autonomous manufacturing driven by AI.

As Song explained, "We are now seeing factory models advance beyond simple automation, with AI beginning to take over the decision-making process itself."

The KETI SMIC center is equipped with high-performance AI servers and a humanoid robot testbed to support autonomous manufacturing, and features a simulation environment based on digital twin technology that enables the process optimization by replicating actual manufacturing.

"It’s difficult for technologies developed in research institutes to be implemented directly in the field,” Song emphasized. “Developers, automation engineers, and on-site operators must work together, speaking the same language and aligning their goals."

For example, solutions like 3D Simulator MELSOFT Gemini and SCADA software GENESIS™ are highly capable, but achieving full proficiency in their use on-site requires time and repeated practice. Song commented, "MECA serves as an effective platform for narrowing this gap. It is the only skills competition in Korea that integrates automation, DX, and AI across all three pillars."

He stated that more integrated competitions like this need to be organized. He highlighted Mitsubishi Electric for consistently packaging their solutions from a practical perspective rather than treating them merely as tools.

He added, "Technology only becomes meaningful when it is put into practice, and doing so requires a deep understanding of the field. In that respect, Mitsubishi Electric is a corporation that understands factories."

The center’s director viewed MECA as a practical alternative to educational infrastructure. He stated, "There is no shortage of technology, but systems for transferring that technology to people are lacking. MECA is not just a skills competition, but a gateway for young talent to step into the industry."

Following the presentations, the judges assess each team’s demonstrations.

- Introduction: Highlights from the first-ever MECA KOREA CUP: "Awakening the power of theory"

- Part 1: Korea’s First MECA KOREA CUP 2025 — Behind the Scenes

- Part 3: Achievements and Outlook — The Awards Ceremony and the Future of MECA