Imaginative eco-solution from winner of the ME Cup India

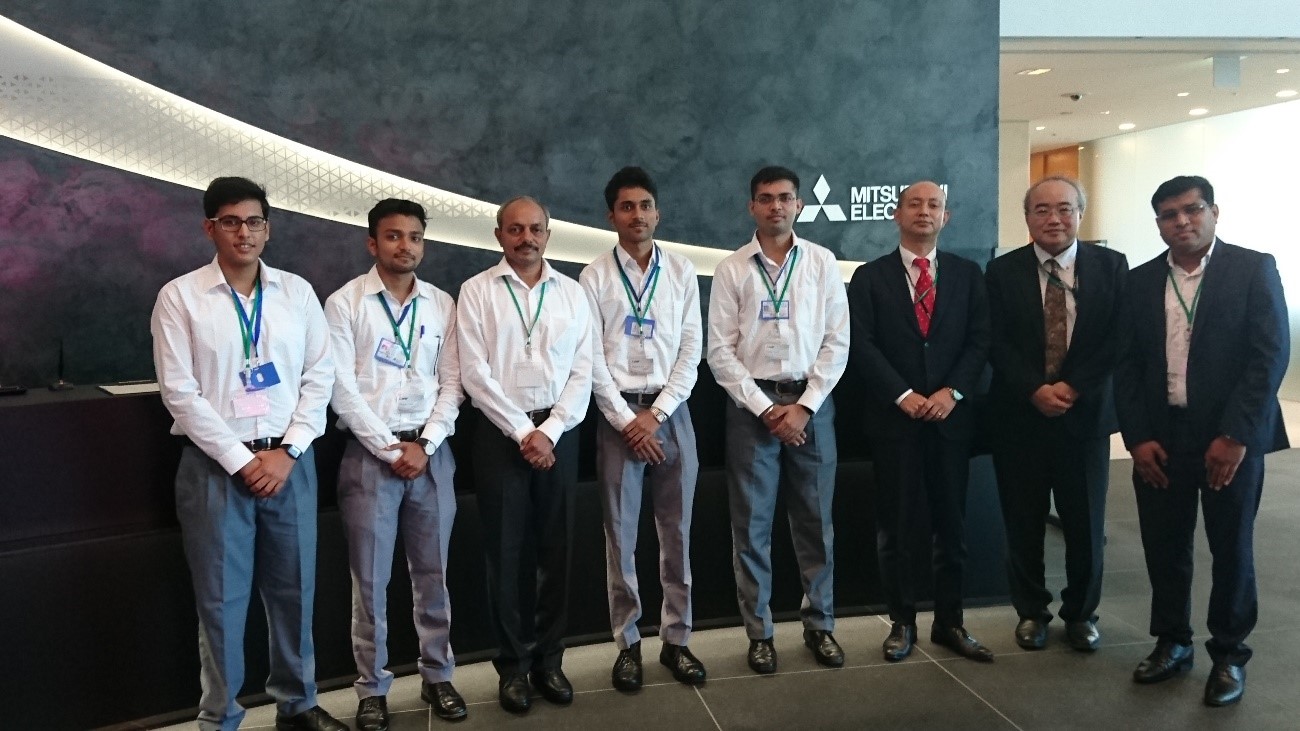

The winners of the Indian ME CUP 2018 started their education and fact finding trip to Japan with a visit to Mitsubishi Electric's headquarters. There they received an award recognizing their outstanding achievement from Eiichi Harada, General Manager of the FA Overseas Planning & Administration Department.

During the visit the winning team from the Dayalbagh Education Institute in Agra explained about their solution for a Multipurpose Mobile Powerhouse. Following this they moved on to various Mitsubishi Electric Works and factories to study and learn more about the latest e-F@ctory smart manufacturing initiatives.

2018 saw the final of the 3rd ME Cup in India. This annual competition brought together 35 teams from Universities, technical colleges and other higher education establishments from across India to this year’s host, The Institute of Technology, Nirma University in Ahmedabad. The final presentation and judging took place February 16th-17th 2018 but the hard work had already begun 6 months earlier for the qualifying teams.

Each of the 35 teams consisted of four members and a supervising professor/lecturer and were united under the challenge of "Innovative Solutions for Smart Manufacturing". The teams had a standard automation tool box which formed the base of the solution, with other items being added as needed. What resulted was a diverse and exciting set of ideas from automated food preparation to smart warehouse management systems.

The efforts of the teams were both imaginative and well executed which made the task of finding a winner by the seven judges quite difficult!

You can understand just how difficult when you hear about the winners solution.

The Dayalbagh team members were Punarvasu Sharma, Mehar Saran, Achraj Prakash and team leader Abeer Saxena. They were supported by their mentor, Professor Bhagwan Das. Mr Saxena explained the Multipurpose Mobile Powerhouse really is a “veritable Swiss Army knife of a solution” to some real problems facing the development of rural India. He commented that electricity is something most of us take for granted; it is central to many aspects of our lives from cooking, to water delivery, to communications and entertainment. It is also what drives our industries. However, for 14% of India they have never seen or experienced electricity, while significant other parts may have an indeterminate supply.

So the team set about designing a fully mobile power generator based on solar power. During transportation its panels are neatly folded away but arriving at the operation site the panels can be automatically deployed, extending outwards on three sides of the unit. The use of solar power was no accident as the team considered the unit would be both eco-friendly but also self-sufficient. Part of the reasoning was it could be a big aid after a natural disaster such as an earthquake providing essential power for communications but without the reliance on fossil fuels which might be in short supply. After charging the unit’s batteries could output power for the unit to “drive” itself on electric motors as well as DC, single phase AC or three phase AC supplies for secondary uses. This meant the Powerhouse could support operations of mobile canteens, drive field pumps for better irrigation as well as a myriad of other critical uses even such as driving water pumps for emergency firefighting procedures. But there was more. Also built in to the Powerhouse was a forklift function to aid lifting of heavy loads, which was of course driven from its own battery storage. So this flexible solution really targeted an important developmental and social need utilizing technology, ingenuity and enthusiasm to change something for the better.

Overall we should commend all of the participants of the ME Cup 2018 for their dedication and hard work. If this is an example of how India is getting behind their “Make in India” campaign then we can expect great things in the future from these budding engineers.

Five members of the Dayalbagh team (left hand side) and their mentor, Professor Bhagwan Das (center) welcomed by Eiichi Harada, Yoshihiro Fujita and Shrikant Takale.

Note: All trademarks acknowledged.