First released April, 2025

Gunze Limited is now using Mitsubishi Electric’s EcoWebServerIII and EcoAdviser to centrally monitor power usage across ten offices and factories in Japan. By leveraging these solutions, the company’s head office can analyze energy consumption trends, identify areas for improvement, and encourage energy-saving initiatives across all locations. Staff at individual sites can also access this data to track the impact of their energy efficiency efforts, fostering a culture of continuous improvement.

Key Points:

- 1. Visualizing power usage across ten locations for better energy efficiency.

- 2. Management and on-site staff can independently create their own user-friendly dashboards without requiring any programming skills.

- 3. Direct data collection from PLCs enables minute-by-minute monitoring of power usage.

GUNZE LIMITED

Originally established as an innerwear manufacturer, Gunze has since expanded into other industries, including plastic films for beverage packaging, engineering plastics for printers and photocopiers, and medical materials such as artificial skin. These products are primarily manufactured at the company’s domestic and overseas factories or through affiliated businesses.

As well as innerwear, Gunze produces engineering plastics, medical materials, and more.

Left: Seamless belts made from engineering plastics, suitable for a variety of uses. Right: An example of artificial skin composed of two layers; a collagen sponge and a silicone film.

As well as innerwear, Gunze produces engineering plastics, medical materials, and more.

Top: Seamless belts made from engineering plastics, suitable for a variety of uses. Bottom: An example of artificial skin composed of two layers; a collagen sponge and a silicone film.

Gunze’s head office oversees infrastructure management across all production sites, including manufacturing technology, IT technology, and environmental initiatives. As part of the company’s sustainability efforts, it has prioritized energy efficiency by enhancing the visualization of power consumption.

Until 2007, Gunze used an in-house system to visualize energy data logged by a PLC system.

“We collected hourly data with PLCs and used this data to compile daily reports,” says Masaru Ida, manager of the Production Administration Technology & Development Department, who had been involved in the creation of the original energy-saving system at one of the factories. “But this required engineers to develop the system, and the scope for future expansion was limited. We also published a monthly ranking of energy-saving results for each office. We were starting to feel like we had run out of ways to save energy and needed new ideas.”

In search of better solutions, Gunze adopted both EcoWebServerII and EcoMonitor at one of its factories after observing similar implementations at Mitsubishi Electric’s Fukuyama Works. These solutions integrated seamlessly with existing Mitsubishi Electric PLCs, enabling real-time data collection, and providing clear metrics for energy-saving actions. Recognizing the system’s effectiveness, Gunze expanded its use company-wide.

Centralized management extends energy saving effects to the whole company

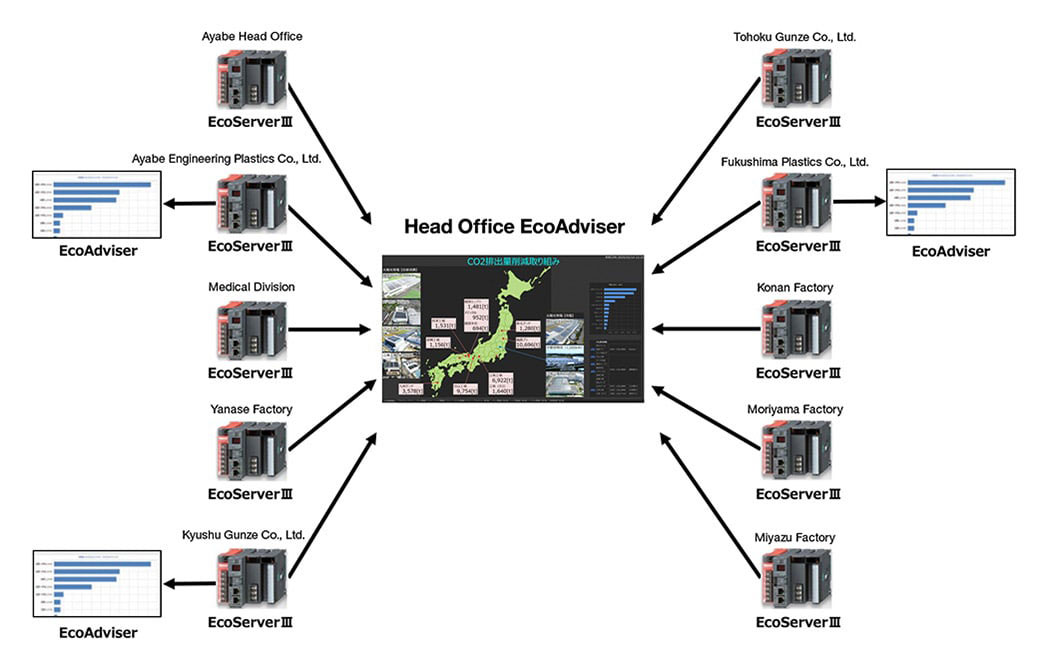

Gunze later upgraded to the latest EcoWebServerIII, which enabled power usage data to be collected from equipment across multiple facilities. However, the administrative department soon realized that they needed a way to monitor and compare power usage across locations. Its setup meant that each EcoWebServer its data separately, so the company needed a system to unify this information.

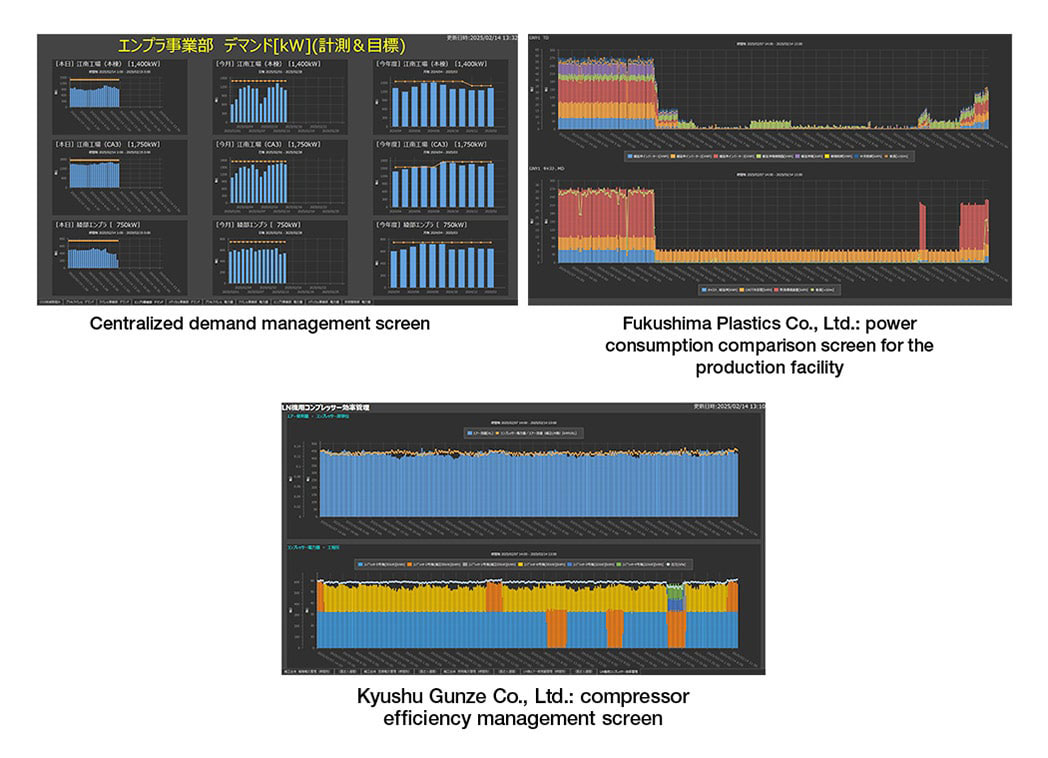

To address this, in 2020, Gunze introduced EcoAdviser, Mitsubishi Electric’s advanced energy-saving support software. EcoAdviser centralizes and visualizes data from multiple EcoWebServerIII units, presenting it in user-friendly graphs, charts, and maps. This enables Gunze’s head office to compare energy consumption across all sites, identify trends, and implement targeted energy efficiency improvements.

EcoAdviser displays energy information clearly as graphs and charts.

Gunze’s head office uses EcoAdviser to monitor and visualize energy consumption across ten offices, factories, and affiliated companies in Japan. While energy-saving measures are implemented daily at each site, variations in production facilities and schedules require tailored approaches to efficiency. With EcoAdviser, Gunze can analyze performance data and provide location-specific recommendations for improvement.

Beyond centralized management at the head office, individual locations have also adopted EcoAdviser, enabling them to track their own energy consumption, assess the impact of their initiatives, and set independent efficiency goals.

The head office uses EcoAdviser for centralized management of energy usage data from ten locations around Japan.

To effectively visualize energy data with EcoAdviser, Gunze needed a way to develop customized energy management screens. This process proved to be remarkably simple, as Takeshi Umetani of the Production Administration Technology & Development Department explains: “We just had to place parts on the screen with the mouse. Previously, we had used BASIC or VBA to create energy management screens, but with EcoAdviser, we were able to create screens without any programming knowledge.”

This user-friendly functionality has enabled both the Production Administration Technology & Development Department and local staff at each site to create their own customized dashboards. As a result, Gunze has achieved more advanced energy visualization and continuous improvements across its facilities.

“Playing with the data”

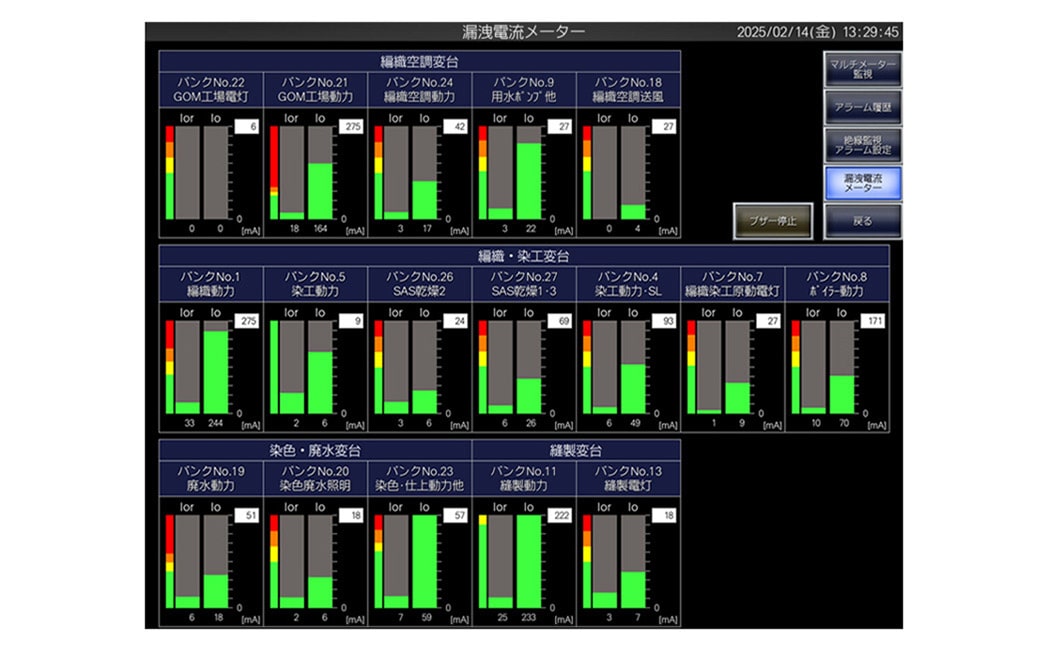

Building on its energy management efforts, Gunze is now also integrating production data from PLCs to understand the energy usage per unit of production. This approach allows the company to refine efficiency strategies further. Additionally, individual factories are developing their own enhancements, such as the Yanase Factory in Asago (Hyogo Prefecture), which has introduced preventive maintenance measures by using SoftGOT to monitor wiring insulation in real time.

Visualization screen using SoftGOT

The Yanase Factory is using SoftGOT to achieve minute-by-minute visualization.

While EcoAdviser gathers energy data from EcoWebServerIII on an hourly basis, GOTs, which were originally designed for equipment control, enable near real-time data visualization. Additionally, they are using SoftGOT, which reproduces GOT functions on a PC, to collect power usage information directly from PLCs, so that Gunze can now monitor power consumption minute-by-minute. “The system can be used in all kinds of ways, almost like playing with the data. I think this is a benefit of Mitsubishi Electric’s energy-saving solutions,” says Kazuki Ikuta.

Although Gunze has used EcoWebServerIII and EcoAdviser to successfully centralize energy management across ten locations, Masaru Ida says the company now wants to expand its goal managing all locations and facilities: “We want to expand the system to cover other production locations and additional equipment, creating a system that will continue to grow in effectiveness.”

Members of Gunze Limited’s Production Administration Technology & Development Department involved in visualization of energy usage.

From left to right: Kazuki Ikuta, Masaru Ida, Takeshi Umetani

Products and Solutions

GUNZE LIMITED

- Established: 1896

- Business areas: Functional Solutions, Medical Materials, Apparel, and Lifestyle Creations

- URL : https://www.gunze.co.jp/english/