Human-Machine Interfaces(HMIs)-GOT GOT2000 Series

- Parameter setting

- Test operation

- One-touch tuning function

- Tuning function

- Servo amplifier graph function (startup, adjustment)

- FA transparent function

- System launcher (servo network) function

- Drive recorder function

- Servo amplifier data analysis

- Servo amplifier graph function (maintenance)

- Backup/Restoration function

- Monitor function

- R motion monitor function/Q motion monitor function

- R motion SFC monitor function/Q motion SFC monitor function

- Motion program editor function

- Servo amplifier monitor function

- Intelligent module monitor function

- Alarm display function

- Encoder communication circuit diagnosis

- Machine diagnosis (friction estimation, vibration estimation)

- Machine diagnosis (tension estimation)

- Machine diagnosis (total travel distance)

- Gear Failure Diagnosis

- Machine diagnosis function

- Machine failure prediction function

- Servo amplifier life diagnosis function

- Switching axis numbers (station numbers) of servo amplifiers

Maintenance

MR-J4 MR-JEMachine diagnosis function

screen End user Predictive

maintenance Maintenance

(Single-ch)* GT SoftGOT2000

(Multi-ch)

- *Supported by MR-J4-□B(-RJ), MR-J4W2-□B, MR-J4W3-□B, MR-JE-□B only.

See Supported models and versions for details.

With the on-site GOT, you can find out the maintenance timing of the equipment drive parts

Challenges

How can I predict deterioration of a machine if it has excessive load and is frequently accelerated?

Solutions

GOT can display estimated values (machine friction, torque vibration, etc.) that are collected by the machine diagnosis function of the servo amplifier. The difference between the initial value (at the startup) and the current value can be used to predict deterioration of the machine. Using this function with the GOT's alarm function will help you perform timely maintenance of machine parts.

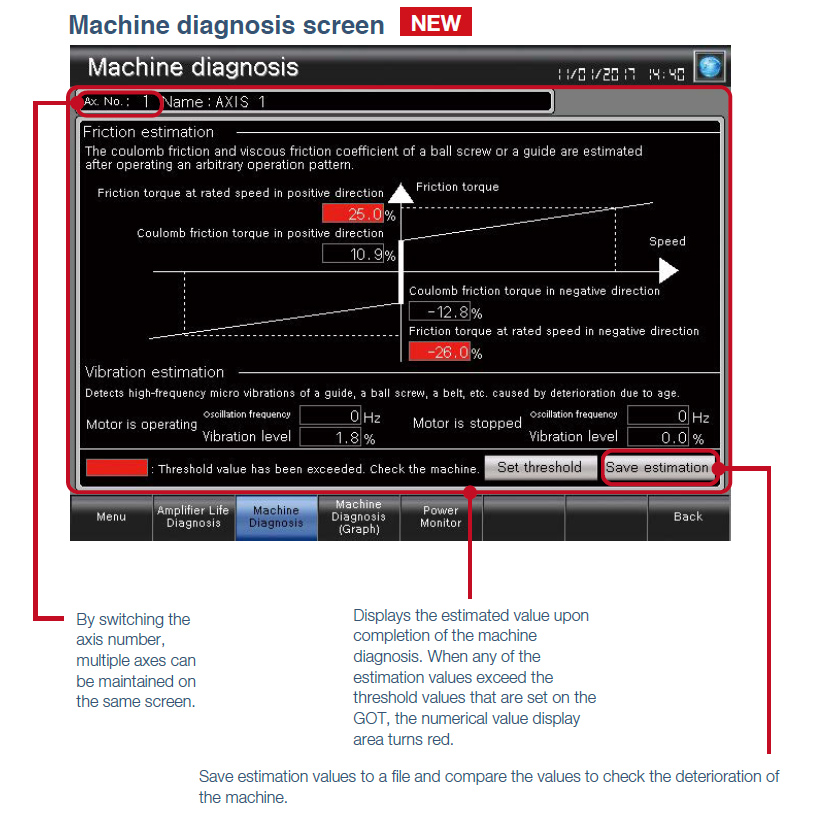

Descriptions of items on the machine diagnosis screen

| Estimated friction value | Description | |

|---|---|---|

| Estimated friction value | Detect the estimated static friction (coulomb friction) (including gravity and etc.) and dynamic friction (viscous friction) coefficient of guides or ball screws according to the operation patterns. | |

| Friction torque at rated speed (%) | Friction in operation at the rated speed. The value indicates the ratio (%) against the rated torque. The value increases as the machine deteriorates. |

|

| Static friction (coulomb friction) (%) | Regardless of the motor speed, a constant value is applied to friction. When an object begins to move, the torque must be greater than or equal to the static friction (coulomb friction) torque. The value indicates the ratio (%) against the rated torque. The value increases as the machine deteriorates. |

|

| Vibration estimation | The vibration estimation function observes the torque vibration and estimates the vibration level and the vibration frequency of high-frequency micro vibrations. This function allows checking of the increase of vibration level and the change in the vibration frequency that are caused by deterioration of a guide, a ball screw, a belt, etc. due to age. |

|

| Oscillation frequency (Hz) | Frequency of torque vibration when a machine vibrates during operation or when it is not operating. The value indicates the frequency when the machine oscillates due to a cause such as deterioration of the machine due to age. |

|

| Vibration level (%) | Torque amplitude when a machine vibrates during operation or when it is not operating. The value indicates the ratio (%) against the rated torque. The value increases as the machine oscillation increases due to a cause such as deterioration of the machine due to age. |

|

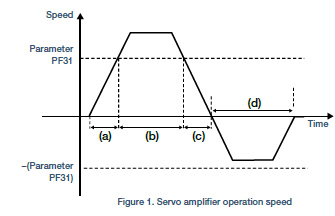

Friction estimation by using the machine diagnosis function

Friction estimation results are obtained when the following conditions are satisfied:

- The machine was operated for 150 seconds or more at a motor rotation speed or linear servo motor speed equal to or above the value set for parameter [Pr. PF 31].

- The machine was operated for 150 seconds or more at a motor rotation speed or linear servo motor speed below the value set for parameter [Pr. PF 31].

The value of parameter [Pr. PF 31] is treated as an absolute value. Use a positive number for operating the machine in the forward rotation direction and a negative

number for operating it in the reverse rotation direction.

In the case of the operation pattern shown in Figure 1, when both (a)+(c) and (b) are operated in the forward rotation direction for 150 seconds or more, a friction estimation result can be obtained.

The friction estimation in the reverse rotation direction cannot be obtained because the speed during the reverse rotation direction operation ((d)) does not exceed the value of parameter [Pr. PF 31].

Change the value of parameter [Pr. PF 31] and perform the friction estimation.

Also, when the value of the parameter [Pr. PF 31] is 0, the threshold value is the rated rotational speed or half the rated speed.

- *PF31: Machine diagnosis function - Friction judgment speed

- *For the details of the machine diagnosis function, please refer to MR Configurator2 Help.

●: Supported - : Not supported

| No. | Function |

MR-J5-□G(-RJ) MR-J5W2-□G MR-J5W3-□G |

MR-J5D1-□G4 MR-J5D2-□G4 MR-J5D3-□G4 |

MR-J5-□B(-RJ) MR-J5W2-□B MR-J5W3-□B |

MR-J4-□B(-RJ) MR-J4W2-□B MR-J4W3-□B |

MR-J4-□A-RJ | MR-J4-□GF(-RJ) | MR-JET-□G | MR-JE-□B | MR-JE-□A | MR-JE-□C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Machine diagnosis function | - | - | - | ● | ● | ● | - | ● | ● | ● |