Solutions

IoT Solutions for Machining Lines

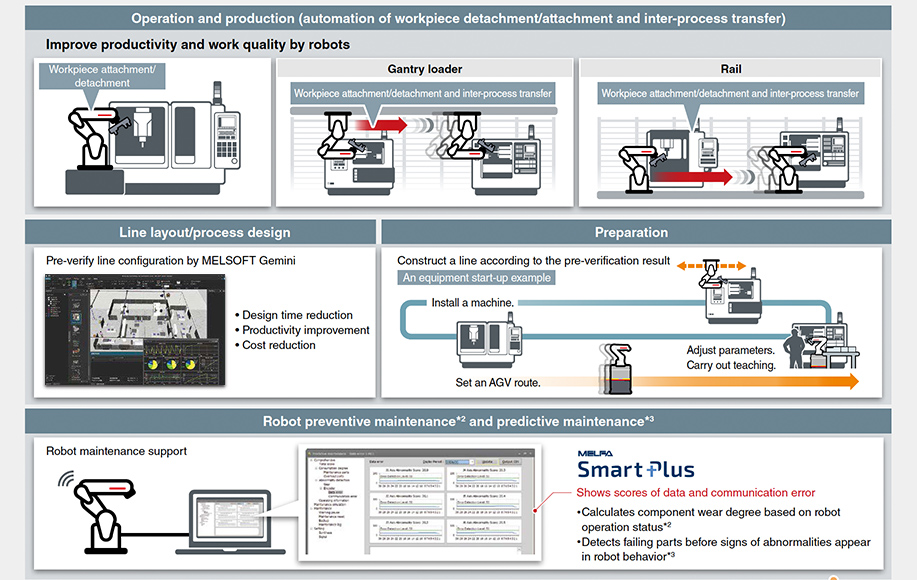

Case.09Improving productivity and work quality by using robots

- Automation

- Digital twin

- Individual equipment

- Overall line

- Overall factory

Issues

Workpieces are handled manually, which leads to human error. (End users)

It takes time to set up lines when replacing manual labor with robots.

(Line/equipment design engineers)

Concern about maintenance of robots. (End users)

It takes time to set up lines when replacing manual labor with robots.

(Line/equipment design engineers)

Concern about maintenance of robots. (End users)

Solution

- Automate attachment/detachment and inter-process transfer of workpieces by combining robots, machine tools, and automated guided vehicles (AGV) (For end users)

- Pre-verify line configuration with robots by using MELSOFT Gemini (For line/equipment design engineers)

- Systematize robot maintenance by using the predictive and preventive maintenance functions of SmartPlus (For end users)

- *1Supported by MELFA FR series/CR series

- *2Supported by MELFA Smart A type.

- *3Supported by MELFA Smart B type.

Benefits

- Improve productivity and work quality by optimizing the entire engineering chain

- Reduce line startup time

- Reduce maintenance time