Solutions

Electrical & Electronic

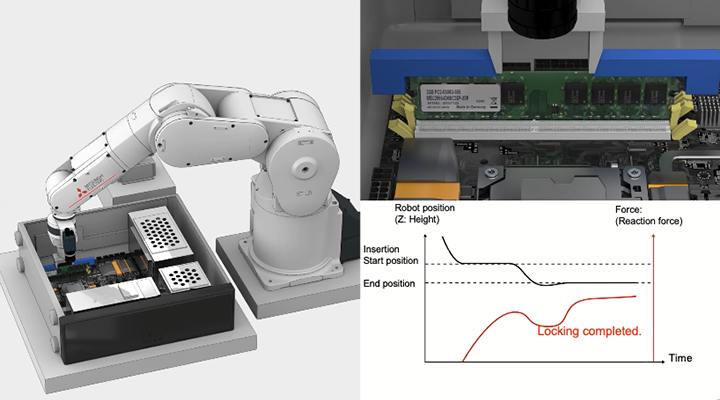

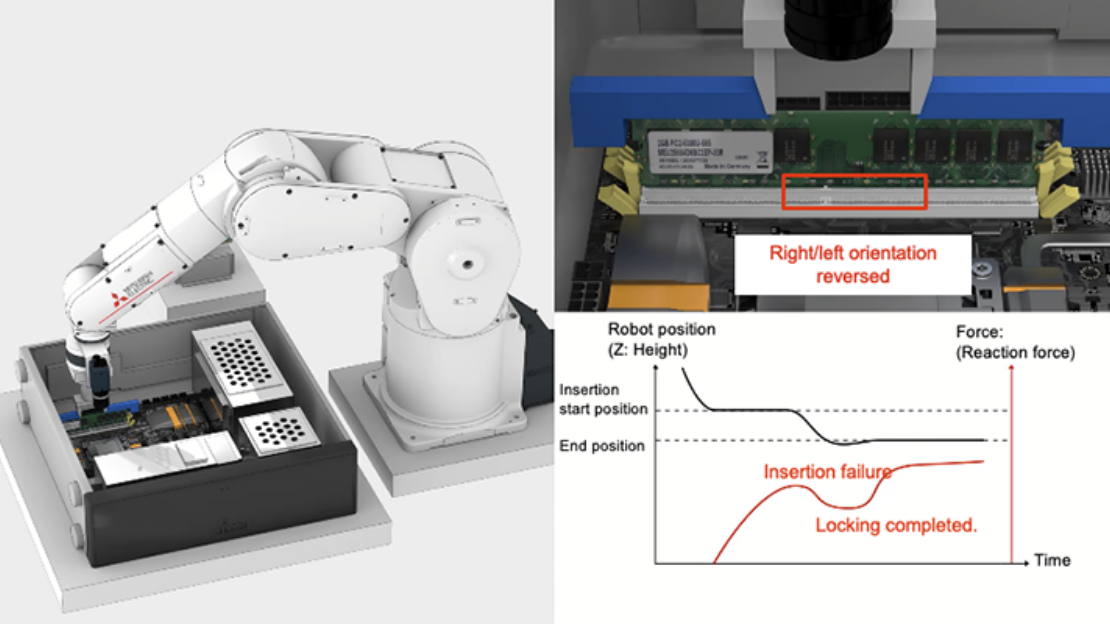

Precision assembly of parts (memory) through

One robot removes and inserts memory cards. Force sensors are used to sense pressure and detect abnormalities and assembly completion.

Memory card assembly example

Solutions to the Issues

Issues

Demands for automation unaffected by variations in parts processing accuracy (dimensions) and assembly accuracy of upstream processes are increasing. For assembly that requires precision assembly while protecting parts, in some cases it’s necessary to press with a certain force for a certain amount of time, and in some cases it’s necessary to record it.

Solutions

- Robot takes out a memory.

- Vision sensor checks the workpiece position.

- Robot calculates the work position internally using vector calculation methods and moves the memory close to the compensated position.

- Memory is inserted into the circuit board slot (profile control) During this time, force sensor detects the presence/absence of abnormalities and assembly completion.

Points

- 【Part/product loss reduction】

- Force sensors detect and prevent workpiece damage, etc. during apart assembly.

- 【Traceability management】

- Force data during assembly are collected in real time.Data can be utilized for quality control.

- 【Automatic positional adjustment】

- Force sensor and vision sensor compensates for variations in workpiece processing accuracy or set position, contributing to stable equipment operation.

When an abnormality occurs due to workpiece orientation

Workpiece was placed with front and back reversed. The force sensor detects pressure abnormality during insertion. Operation is stopped before the workpiece is damaged.