The Inside View

Can many of the world's challenges be addressed through the collaboration of manufacturing and cyberspace?Dr. Koji Yasui

First Published in Japanese in August 2023 [3 parts]

Part 1: Industry is facing the biggest changes it has seen in centuries.

──The past few years have brought dramatic change to all aspects of society, but how is the world of industry changing?

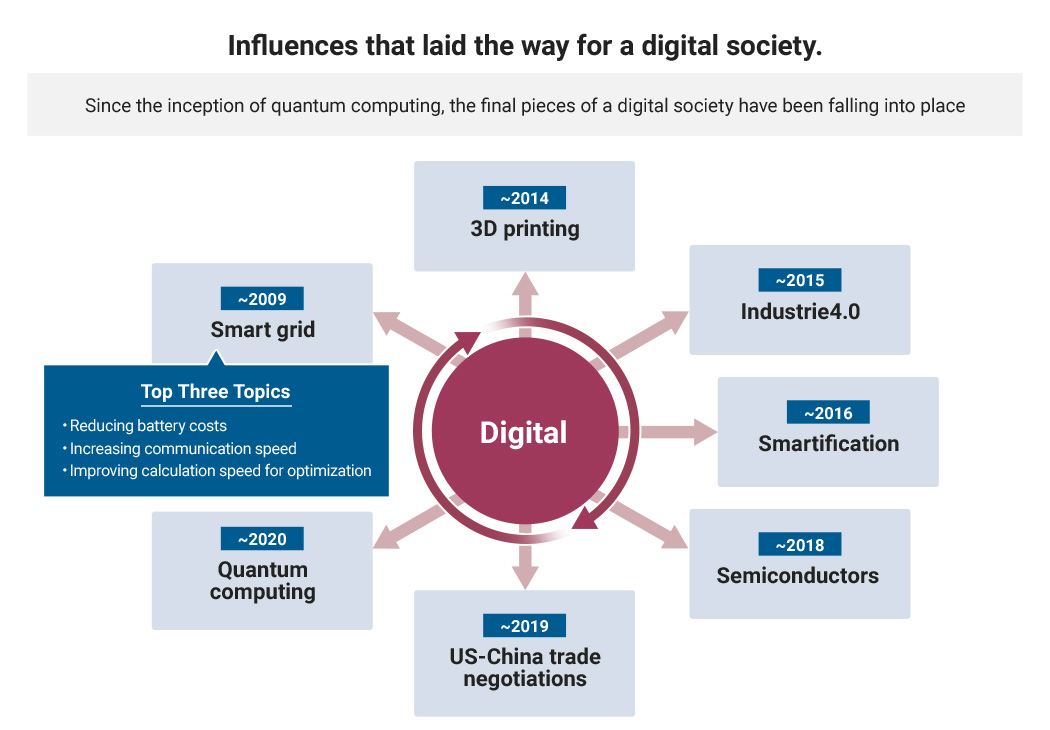

We've been saying for a long time that the next industrial revolution will be triggered by advances in digital technology. The latest industrial revolution is directed at the smartification of society, whereby all aspects of society will operate in an autonomous and smartly coordinated fashion. For example, smart grids to advance the supply of electricity were promoted by the United States around 2009. This was followed by a boom in 3D printers in 2014, and around 2015, Germany's Industry 4.0 prompted a lot of discussion in Japanese domestic industrial circles.

While the entities involved and the content differs, all these initiatives have the same goal, that is to drive a smart society through various means. Experts predicted that the new industrial revolution would kick off in full swing around 2020. And it is true to say we have seen advances in semiconductors and emerging technologies such as the Internet of Things (IoT), artificial intelligence (AI), 5G communications and blockchains. We have also been starting to see the development of quantum computing and communications. So, 2020 seemed to be a historic year with the industrial revolution really hitting its stride.

Furthermore, through the pandemic digitalization gained momentum, and even in Japan, which lagged far behind, working from home and remote meetings became common practice. It was potentially one of the greatest transformations since the first British industrial revolution 200 years before.

As mentioned, during the pandemic investments in the digitalization of the manufacturing sector soared, particularly around 2021. At its start, many manufacturing sites had to cease operations, while those that could continue production did so owing to digital technologies that allowed remote monitoring and control. With the usefulness of digitalization being more evident than ever to the manufacturing industry, investment got into full swing. Keywords in use before the pandemic, such as digital transformation (DX), became more popular in Japan as many manufacturers started to introduce the Industrial IoT (IIoT) and made improvements in their digital infrastructures.

The smart manufacturing trend spread to electric vehicle (EV) production, where there has been significant investment in the digitalization of battery plants. Furthermore, the semiconductor shortages experienced during the pandemic also led to increased digital investments in that industry, as semiconductors are one of the key components in all electronic products, from batteries to smartphones. Those investments in digitalization are starting to bring results, moreover, key events in 2022 triggered concerns about energy security, especially in Europe, and so digitalization investments also began to expand into the energy sector as well.

Given the background, it is time for manufacturers to start their own digitalization and ride the wave of the latest industrial revolution. Investments in digital technologies are rapidly progressing, particularly in larger corporations, and are expected to accelerate further in the future.

──Amidst society’s call for a rapid application of smarter technology, how is the manufacturing industry addressing this issue?

In Japan, we call the smart society at the heart of the new industrial revolution, Society 5.0. Such smart societies are clearly more resilient to uncertainties, and will be effective in finding solutions to today’s challenges such as energy security. For example, if every household was fitted with solar panels and a battery system, it would be possible for homes to have electricity without relying on the grid.

Thinking about Japan's manufacturing sites, which were already relatively well equipped for smart manufacturing including using remote monitoring and control functionalities, so from an operational point of view they were able to remain largely unaffected during the pandemic. The benefits of using cutting-edge digital technologies not only provided immediate results but also created opportunities. Recently, Japan has also attracted semiconductor manufacturers to the country, creating an environment more conducive to meeting digitalization challenges.

Moreover, I believe that the global push towards a sustainable society presents an opportunity for manufacturers. Let me explain. The digitalization of the EV and energy sectors is a hot topic now, being so closely related to global decarbonization and net zero strategies. From my perspective, Japanese companies across the value chain of applicable technologies have significant opportunities here. For example semiconductor factories, which produce the components used as building blocks for the latest digital technologies, and data centers which process large volumes of digital data, are both intensive energy users. In this regard, energy-saving technologies are exactly what Japanese companies excel at, and the world as a whole is actively looking for these capabilities right now.

──What is key to solving the challenge of making companies smarter? What do companies need, and what should they do?

In terms of making manufacturing smarter, I believe the goal should be to create cyber-physical systems (CPS) that allow companies to optimize their operations and activities in the actual physical space, based on insights from the virtual model. As a first step, it is necessary to establish digital twins (digitized alter egos) of people and machines that exist in the physical world, recreated in cyberspace. Incidentally, cyberspace is not exclusively in the ‘cloud’, but can also be generated using on-premises servers installed within the company’s facilities or it can even extend to 'Edge' devices such as PCs and smartphones.

The origins of the digital twin concept can be found in the development of smart grids back in 2009. This early work has helped to address key challenges to the realization of today’s digitalization. For example, battery storage costs needed to be reduced by a factor of ten whilst the speed of data exchange and computer processing had to increase by a factor of ten to support the data processing needs.

The prices of battery storage are now one-tenth of what they were because of increased investments in EVs. With the introduction of 5G, and work already underway on next generation 6G, communication speeds are expected to exceed today’s requirements. Moreover, progress is being made on practical applications of quantum computing, a technology that can be extremely powerful in the optimization of key activities when compared to conventional computing. Additionally, EV manufacturing sites around the world are already leveraging CPS, including in Japan, where large companies are taking the lead in accelerating such efforts.

As costs are reduced, newer technologies become easier to develop and implement. So, I recommend that manufacturers make use of the most promising current technologies and quickly move on to make their company smarter.