The Inside View

Can many of the world's challenges be addressed through the collaboration of manufacturing and cyberspace?Dr. Koji Yasui

First Published in Japanese in August 2023 [3 parts]

Part 2: Manufacturing capabilities will remain the source of competitiveness in a digital society. Therefore, identify your strengths.

──Small and mid-sized production sites can find connecting their equipment to cyberspace a big challenge. When a company decides to make their factory smarter, what approach should they take and how should they proceed in a practical sense?

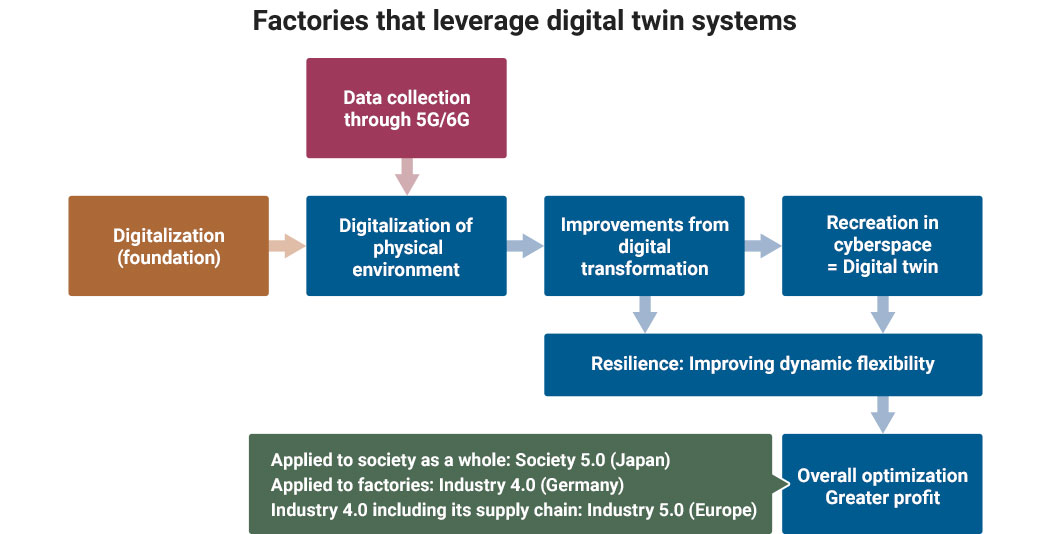

Digital twins used to recreate a manufacturing process in cyberspace are relatively easy to build, especially when it comes to replicating component assembly lines, which is what most larger companies are involved with. However, there can be challenges when it comes to specific machining operations, for example such as grinding and polishing, where many small and mid-sized companies excel, unfortunately it is often the case that these companies have limited budget available for investments.

Addressing this issue has been a global challenge. The Japanese government, for example, has taken a view on scientific and technical innovations from a national perspective, establishing the Strategic Innovation Promotion (SIP) Program. This has strengthened measures for the large-scale adoption of cutting-edge technologies. I was fortunate enough to participate in the program for ‘Technology to Realize Society 5.0 Using Light and Quantum’, and was also actively involved in the social implementation of academic research solutions. Through our work we identified that we are becoming academically and technically capable of converting the machining expertise of skilled workers into digital data. As a result, this kind of technology is now entering an implementation phase within our wider society.

From a manufacturer’s perspective, the reality is digital twins do require some level of investment, so I recommend first looking at small on-site digital improvements that can form the foundation for further smart applications. To achieve this, digitalization budgets should focus on enabling technologies that can drive growth and flexibility to meet changing business conditions.

The strength of digital twins is that we can trial different ideas in cyberspace. This helps us to identify the methods that generate the greatest improvements for the physical processes. Despite digital twins being in cyberspace, they are still based on the physical reality that represents a set of manufacturing capabilities. These capabilities are at the core of a factory's competitiveness, and so the priority should be to strengthen them. Digital twins are an excellent way of improving performance and quality, and subsequently boosting profits.

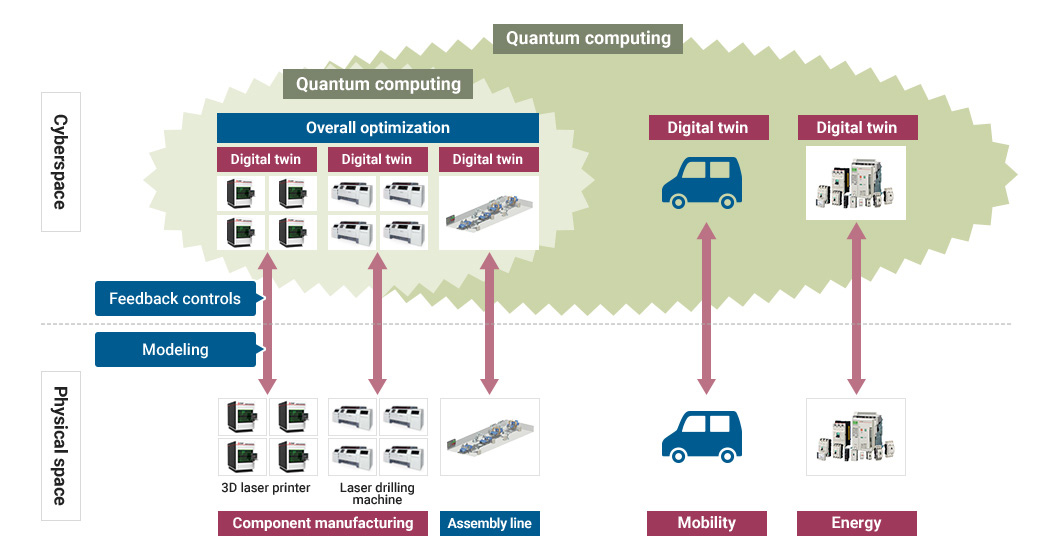

When small or mid-sized companies start to utilize digital twins, this enables the entire supply chain to be optimized with the addition of this missing part. The digital twins developed for the manufacturing industry can also be deployed in the mobility and energy sectors in the form of EV production, as well as in the food and beverage, pharmaceutical and healthcare sectors, which all face global issues and have great potential for development.

The changes we are seeing are the most significant in several hundred years, so it is important not to panic or over-react, but to take time and consider carefully. Every company has unique facets, such as expertise, market knowledge or domain know-how, these core values should be built on. Just as Japan's manufacturing industry is technologically strong in areas such as energy conservation, other countries and companies should identify their unique strengths as well. I believe one important step of the journey is to utilize new tools such as digital twins, IoT, AI and 5G to support each company’s smarter development of their inherent strengths.

First, companies should review their capabilities and polish their strengths. It is important to then actively communicate these to the rest of the world and develop them further. Becoming smarter can be a tool for communicating a company’s strengths to the outside world and connecting with partners who can best leverage the technology.