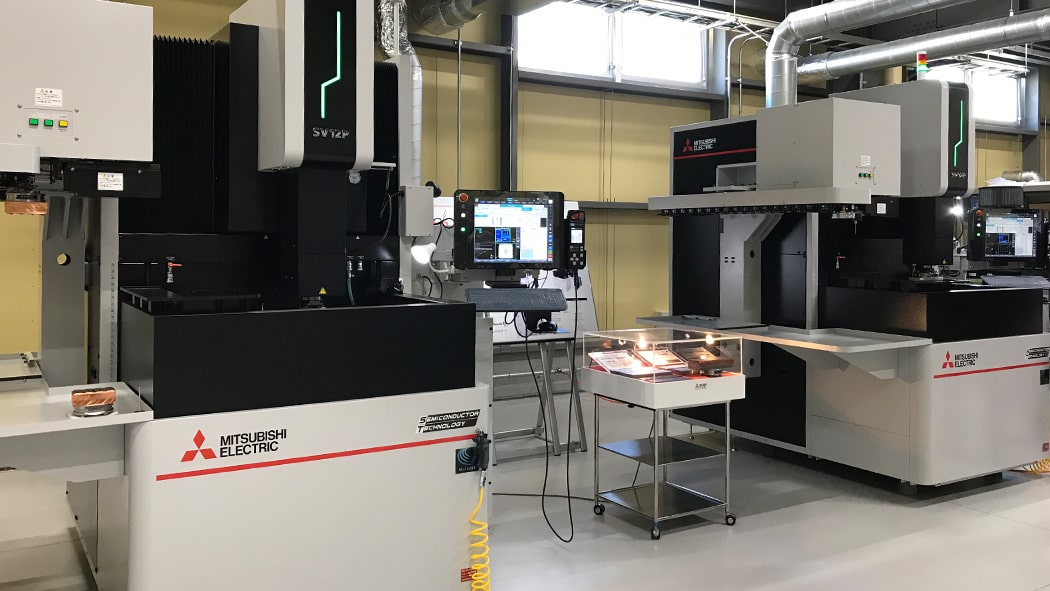

The goal: A machine that can produce high-quality semiconductor encapsulation molds without relying on the technical skill of the manufacturer. As Mitsubishi Electric moved closer to making this concept a reality, one potential user began to show great interest: it was none other than CAPABLE, the company that had refused to even test the initial sample.

In December 2022, Shotaro Osono, who oversees EDM sales and marketing at Mitsubishi Electric, heard from CAPABLE about their plans to open a training center for engineers from mold manufacturers, and that they wanted to use the die-sinking EDM machine with its semiconductor package, currently under development at Mitsubishi Electric, at this training center. It was only 18 months since the initial sample was “turned away at the door”, and less than six months since CAPABLE had finally accepted the third sample. Osono was astounded by how rapidly the situation had developed.

Mitsubishi Electric’s relationship with CAPABLE grew increasingly strong, and in February 2023, the two companies gave a joint lecture at a seminar hosted by the Japan Die & Mold Industry Association. Mold manufacturers see CAPABLE as a powerful presence, forging a new future for Japan’s molding industry. The fact that Mitsubishi Electric presented jointly with CAPABLE had a huge impact within the industry. After the lecture, many companies expressed an interest in entering semiconductor mold manufacturing.

Seminar held jointly with CAPABLE: “Trends in the semiconductor industry and Mitsubishi Electric's EDM machines” (photo shows President Kawahara of CAPABLE speaking at the seminar)

The reason CAPABLE became so positive towards Mitsubishi Electric’s EDM machine was because they saw how seriously Mitsubishi Electric went about the development process. Yoichi Kawahara, President of CAPABLE, said,

“Mitsubishi Electric was a total latecomer to the semiconductor sector, we assumed they had no interest in semiconductor manufacturing, I was surprised that they could make exactly what we wanted in under two years.”

When President Kawahara said, “what we wanted”, he meant a system allowing mold manufacturers to produce high-quality semiconductor encapsulation molds without relying on the skill level of the engineers. If a manufacturer is highly proficient in using die-sinking EDM machines, they would be able to start manufacturing semiconductor encapsulation molds on their own without support from CAPABLE. But the reality is that not many Japanese manufacturers have this level of skill. CAPABLE’s objective is to increase the number of partners who can produce the molds that semiconductor manufacturers want and raise the level of Japan’s molding industry at the same time. Mitsubishi Electric’s processing machines, which can handle any surface roughness and mold shape simply by setting preset parameters, match CAPABLE’s vision perfectly.

Yoichi Kawahara

President, CAPABLE Corporation

Born in Osaka Prefecture. After graduation he joined Marubeni Corporation, serving as manager of the Electronics Devices Department and IT Division, and external director for ten companies.

Joined TOWA Corporation in 2003, becoming President & COO in 2006. Lead TOWA Corporation’s reconstruction and revitalization program, as well as the development of the semiconductor encapsulation business for automotive applications.

Founded CAPABLE Corporation in 2012 and remains its President and CEO until the present day.