Lineup

Service

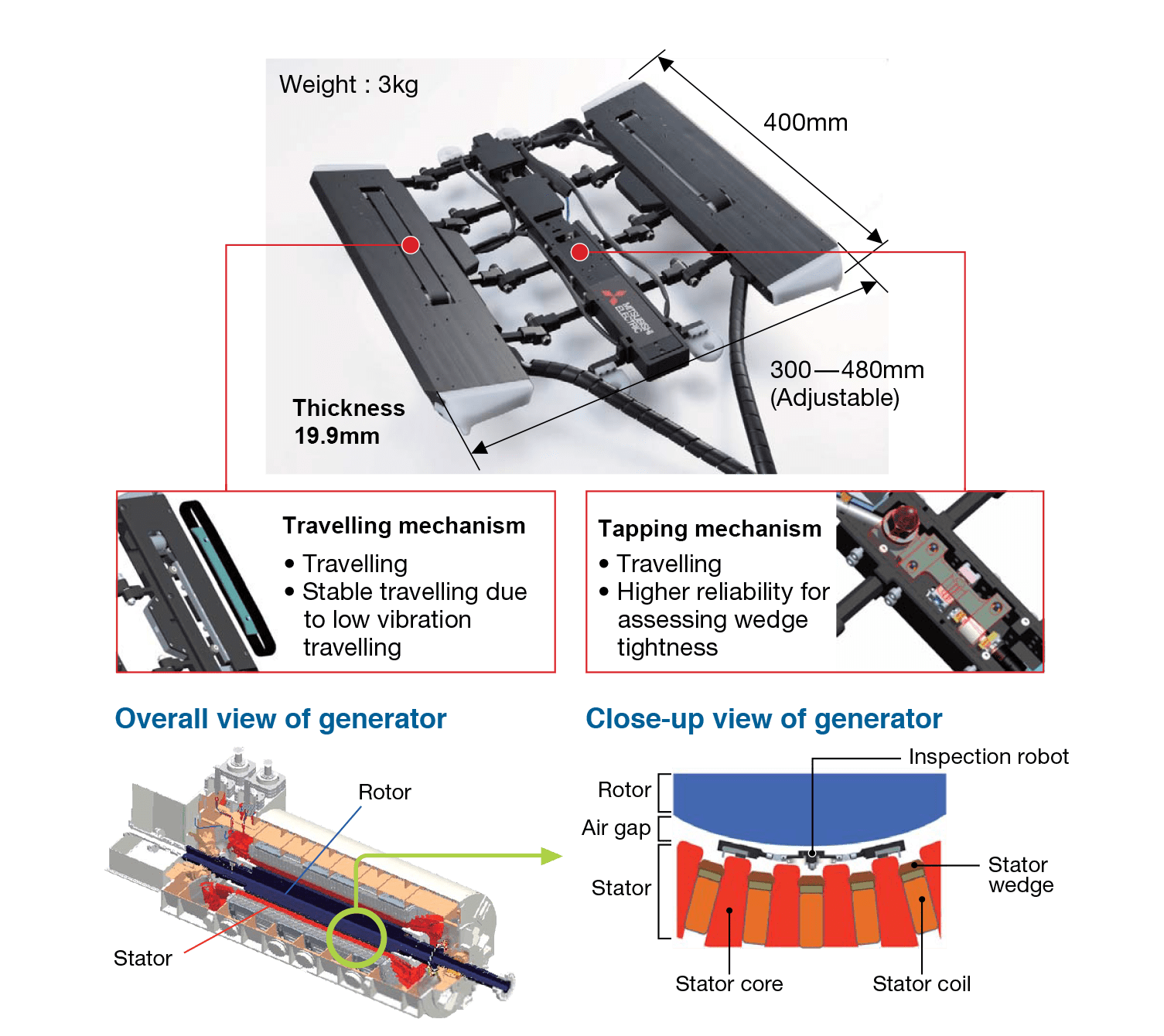

Robotic Inspection

Inspection items by GenSPIDER®

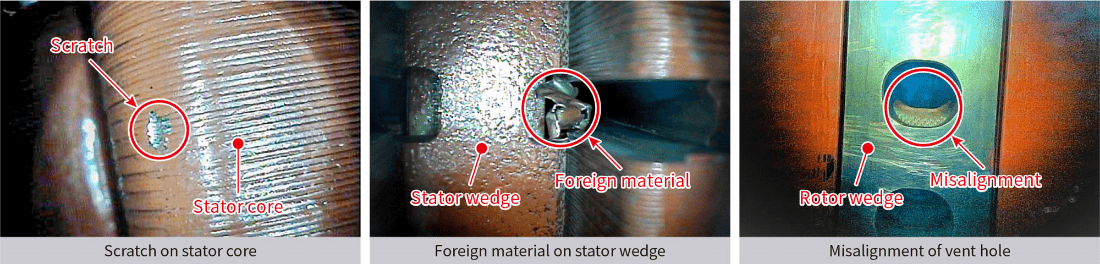

Visual inspection (camera)

GenSPIDER® is equipped with an LED light and a tilted mirror which can be rotated 360 degrees in front of the remote camera installed in the axial direction. This allows GenSPIDER® to take clear images of the stator and rotor in a 180 degree position, even in the dark inside the generator. The remote camera can inspect the rotor ventilation hole and the stator core bore surface without removing the rotor. Early detection of abnormalities is essential to discovering existing issues before they result in a major failure.

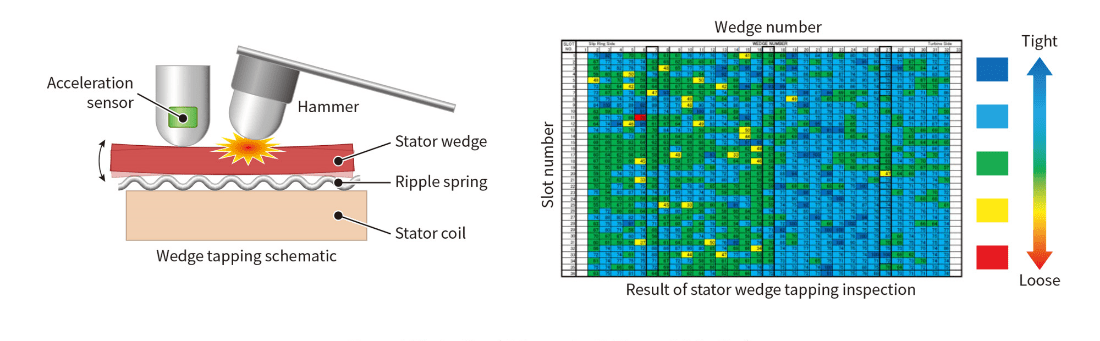

Stator wedge tapping

Stator wedge tapping can be used to check wedge tightness without the rotor pulled out. The tapping mechanism of GenSPIDER® consists of three components: a hammer which vibrates the stator wedge, a motor which drives the hammer, and an accelerometer which detects vibrations on the stator wedge. GenSPIDER® is also equipped with a cam mechanism. Installing the cam driving motor axially on GenSPIDER®’s body results in a thinner body and assurance of sufficient vibration torque. As a result, GenSPIDER® is currently applied to many kinds of generators, providing accurate measurement of stator wedge tightness. Conventionally, inspections of degrees of looseness in stator wedges have been conducted by engineers who then judged the results quantitatively. However, GenSPIDER® quantifies the looseness as numerical data. Accumulating inspection results and analyzing trends enable customers to evaluate the conditions of components in stator core slots. From these results, the number of required spare wedges can be prepared in advance of the next outage.

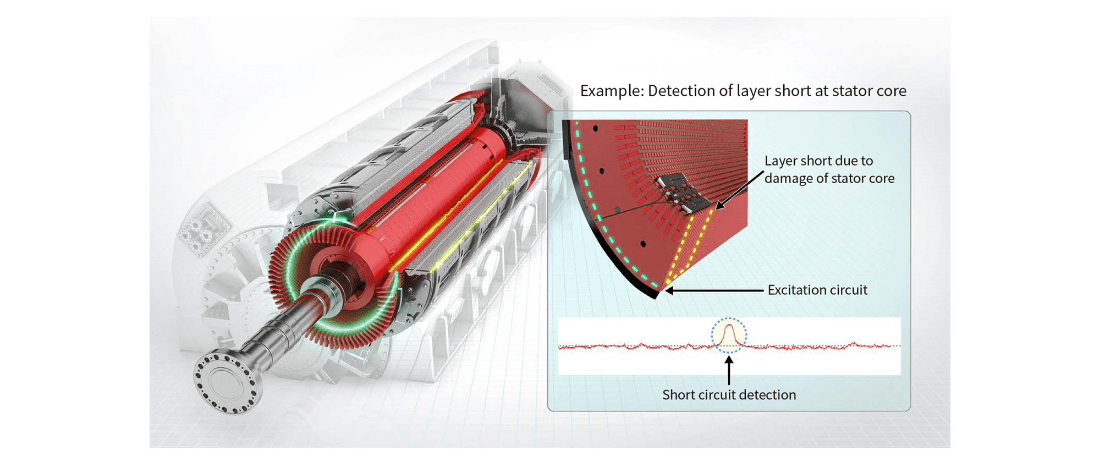

EL-CID test

The EL-CID (Electromagnetic Core Imperfection Detection) test is used to determine the integrity of the inter-laminar insulation in the stator core and identify underlying eddy-current issues. It detects layer shorts at the stator core without the rotor pulled out. Early detection of stator core abnormalities can help avoid serious accidents, and it can be effective in identifying stator core issues prior to major damage during operations.