Lineup

Service

Robotic Inspection

Mitsubishi Electric has developed a dedicated robot capable of inspecting a turbine generator by passing through the narrow gap between the rotor and stator (air gap) to allow fast and reliable in-situ generator inspection.

Mitsubishi Electric’s robotic vehicle GenSPIDER® (Generator Smart & Precise Inspection Accomplished by Generator Dedicated Expert Robot) crawls along the stator core and performs visual inspection by utilizing a built-in high-definition camera. It can save on downtime by enabling the inspection of generator components without the rotor pulled out. Stator wedge tapping and EL-CID® (Electromagnetic Core Imperfection Detection) tests can also be performed by the robot as options.

Note: Power-generator business was transferred to Mitsubishi Generator Co., Ltd on April 1, 2024. Click here for details.

Compact design

GenSPIDER® is designed to perform accurate inspections in air gaps. Thanks to a proprietary traveling mechanism comprising a crawler belt and flat plate, GenSPIDER® has the advantage of a thin 19.9-millimeter profile. It is capable of inspecting most medium to large Mitsubishi Electric generators and non-Mitsubishi Electric generators.

Learn moreQuantitative approach to wedge tapping

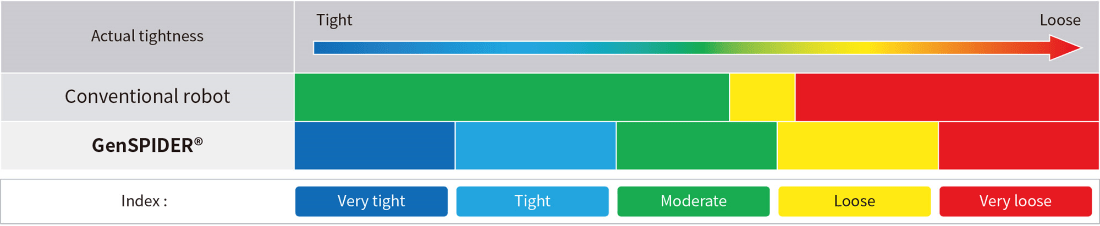

GenSPIDER® can accurately ascertain a full range of stator wedge tightness, from very tight to very loose. Tapping tests are preformed using original vibration analysis technology to accurately evaluate stator wedge tightness in five levels. As a result, GenSPIDER® is able to detect any looseness of stator wedges at an early stage as with inspections carried out manually.

Enhancement of inspection items

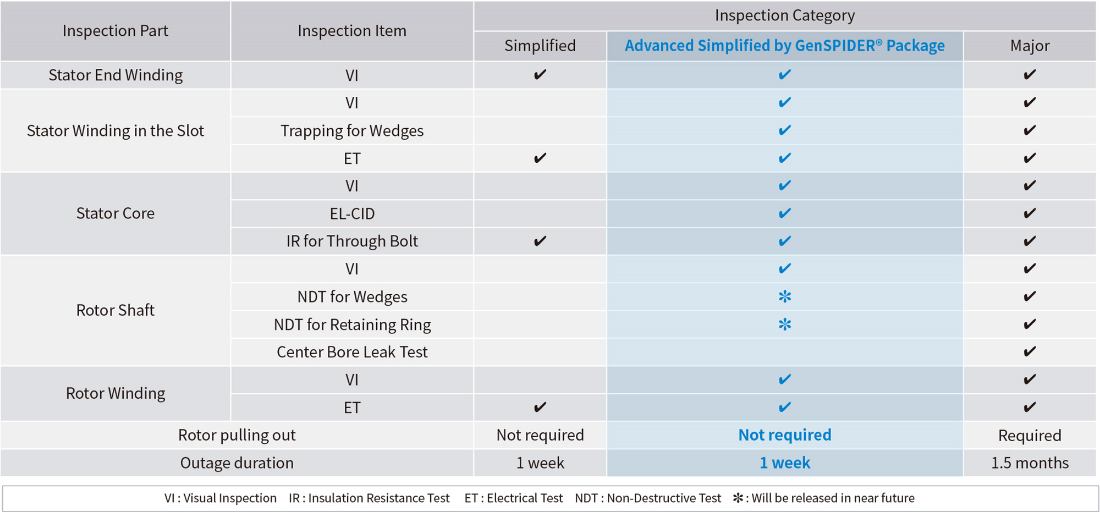

The table below lists the inspection parts and items of a typical generator inspection compared with an “Advanced Simplified” inspection carried out by GenSPIDER®. The Advanced Simplified inspection mostly covers items that are generally included in a major inspection, as opposed to a simplified inspection.