Controllers MELSEC iQ-R Series Product features -Software-

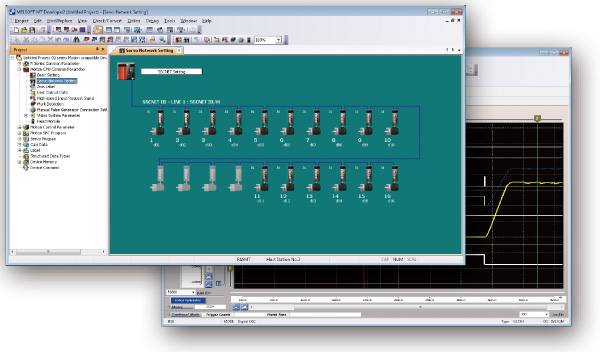

MELSOFT iQ Works is an integrated software suite consisting of GX Works3, MT Works2, GT Works3, RT ToolBox3, FR Configurator2, CW Configurator, and MR Configurator2, which are programming software for each respective product. Integration is further enhanced with MELSOFT Navigator as the central system configuration. The advantages of this powerful integrated software suite are that system design is made much easier with a substantial reduction in repetitious tasks, cutting down on errors while helping to reduce the overall TCO.

Software

FA integrated engineering software

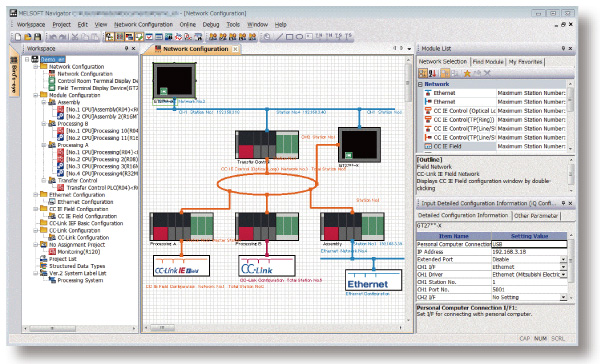

System management software

System level graphic-based configuration tool that simplifies the system design by providing a visual representation of the system. System management features such as system-wide parameterization, labels and block reading of project data are also included.

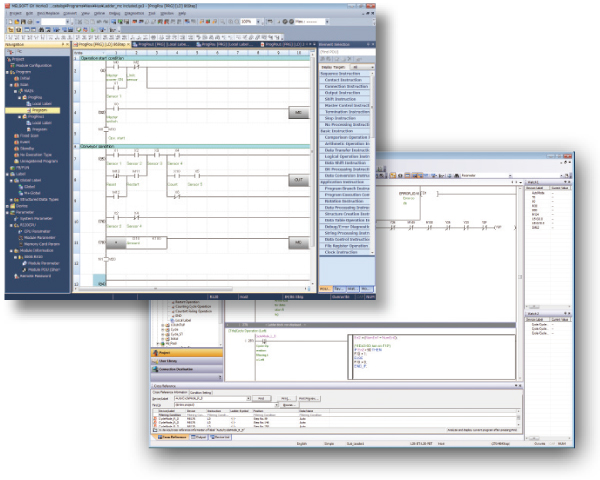

Programmable controller engineering software

Programming and maintenance software specifically designed for the MELSEC iQ-R Series control system.

It includes many features such as graphic-based configuration, simple point and click programming architecture, and diagnostics function enabling easy troubleshooting, reducing engineering cost.

Incorporating backward compatibility of programs created with GX Developer, GX Works2 further improves its functionality resulting in reduced engineering costs.

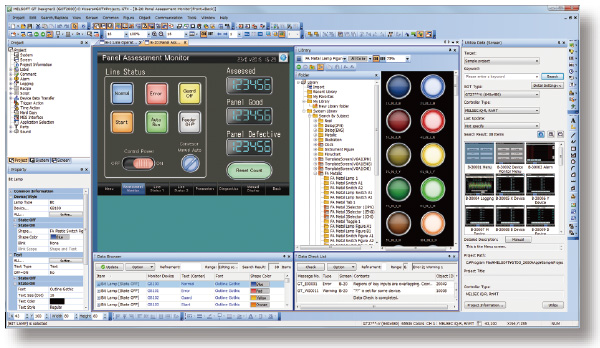

GOT (HMI) screen design software

This graphic operation terminal (GOT) screen creation software is designed with three main features—simplicity, graphics design and operation ease—that help to create graphic screens in fewer steps.

Motion controller engineering software

This motion control design and maintenance software includes intuitive graphic-based programming together with a digital oscilloscope simulator, helping to reduce the motion system TCO.

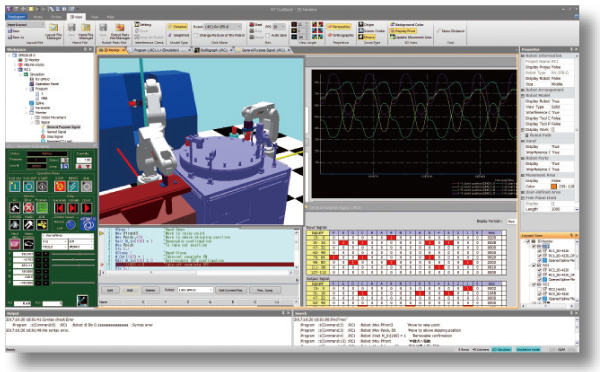

Robot engineering software

This robot engineering software supports various steps from programming, to commissioning, evaluation, and maintenance. In addition, improved preventative maintenance is realized through the use of an integrated 3D robot simulator.

- *1.RT ToolBox3 mini (simplified version) will be installed if iQ Works product ID is used.

If RT ToolBox3 (with simulation function) is required, please purchase RT ToolBox3 or RT ToolBox3 Pro (not the additional license version).

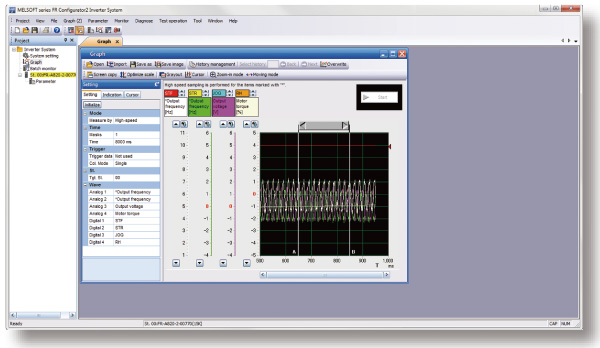

Inverter setup software

This software simplifies settings from the setup to maintenance of inverters.

Parameters can be registered easily and distributed to multiple inverters when replacing, and activation of the PLC function all from one setup screen.

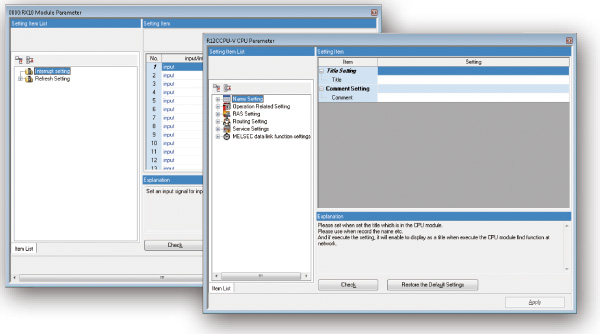

C Controller setting and monitoring tool

This C Controller parameter setting and monitoring software simplifies parameter setting, diagnostics, monitoring and testing. Using CW Configurator is as easy as using the engineering software GX Works3, which shares similar interfaces.

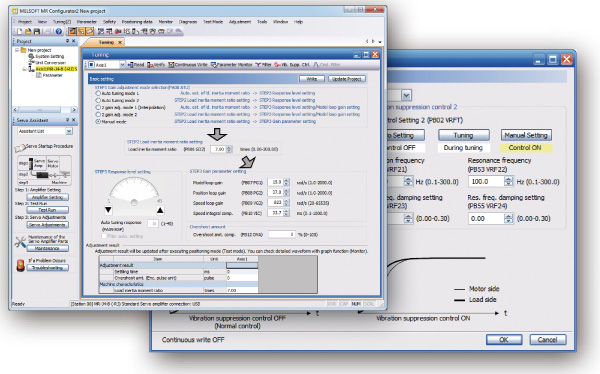

Servo setup software

This servo setup software used for easy monitoring, diagnostics, registering parameters, and testing of the servo amplifier.

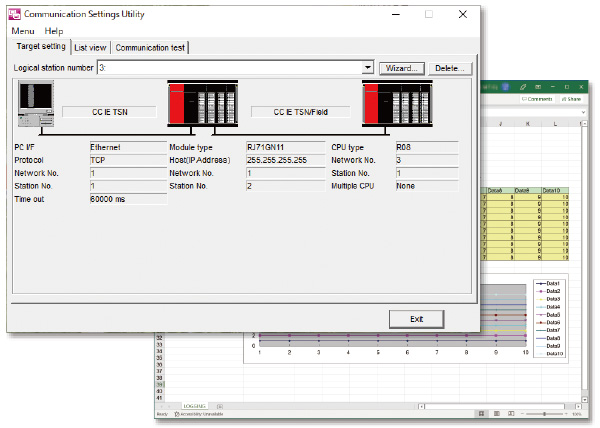

Data access software

MELSOFT MX Component is the ActiveX® control/.NET control library enabling communication from a computer to a programmable controller and motion controller regardless of communication protocol.

Complicated programs for serial and Ethernet communication can be developed with simple steps.

MELSOFT MX Component for iOS/Android™ which can easily develop applications for a mobile device is also available.

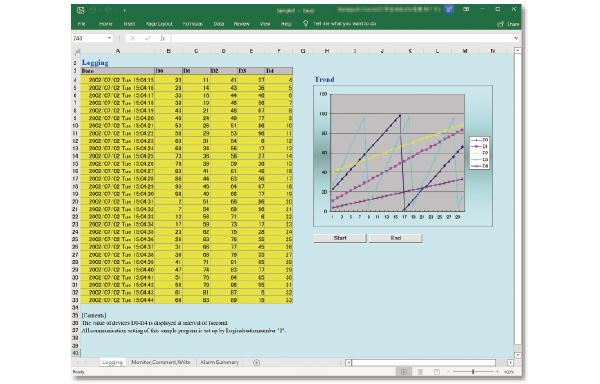

MELSOFT MX Sheet enables monitoring, logging, collecting alarm information, and changing setting values of the programmable controller or motion controller using familiar Excel®.*2 MELSOFT MX Sheet operation conditions can be set from Excel® without requiring a communication program. Production, operation, and alarm information can be confirmed on Excel®, introducing IIoT technologies easily.

- *2.MX Component is required to use MX Sheet.

A bundle package (MX Works) including MX Sheet and MX Component is available

Visualization software

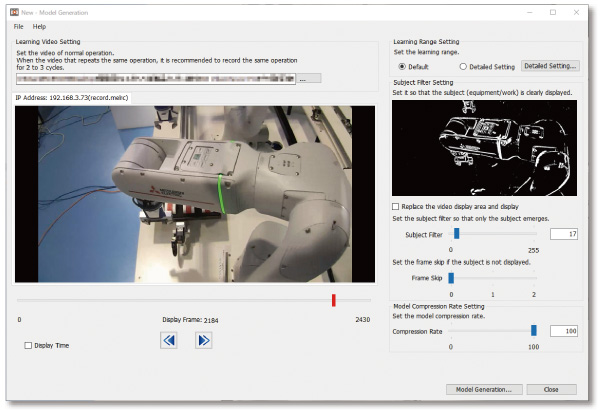

GX VideoViewer Pro automatically extracts differences in a video feed and easily identify an error cause.

Differences in the video feed from normal patterns generated during normal operation are extracted based on “appearance (color, shape, position, etc.)” and “operation (movement amount in unit time)”, then log markers are automatically added.

The error cause can be easily identified in two steps; model generation and difference extraction.

In addition to visualization of data collected by the MELSEC Series, GENESIS64™ manages large volumes of data and provides connectivity to upper-level IT systems such as MES (Manufacturing Execution System). This software enables factories to monitor and analyze data to drive operational excellence.

Simulation software

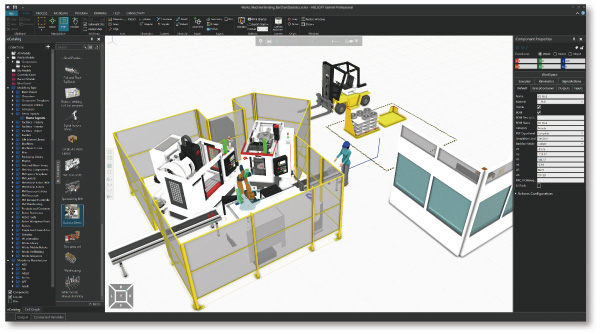

MELSOFT Gemini digitally simulates machine operation and production line processes to enable accelerated design, validation, and optimization of new systems and modifications. With this software, factories can reduce on-site commissioning time and labor and perform more efficient troubleshooting.

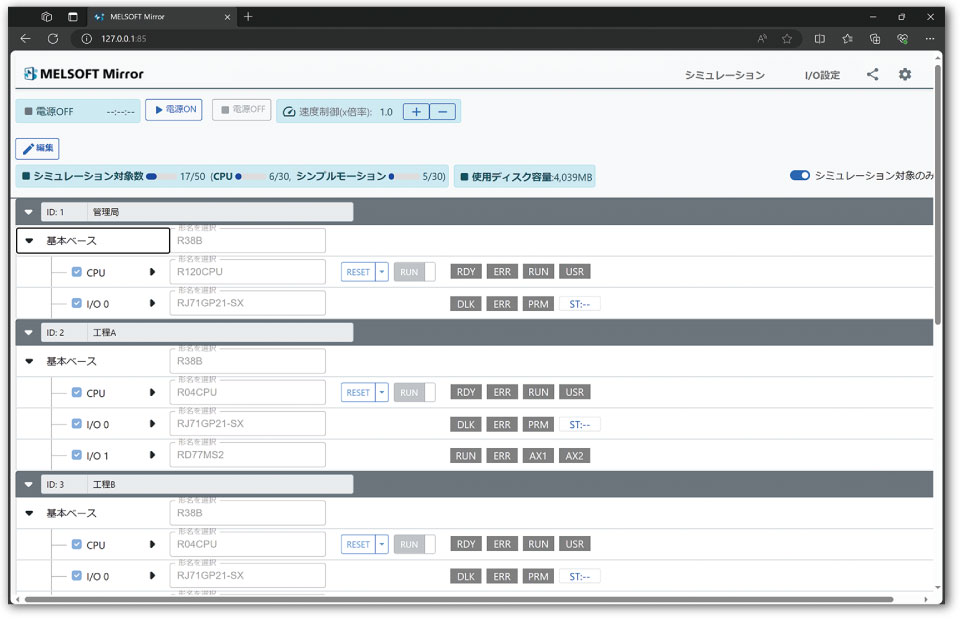

MELSOFT Mirror enables simulation of the entire control system on the shop floor.

Efficiently simulate control logic, including I/O and inter-stage processes, for large systems without using physical devices, regardless of location or number of people.

This enables front-loading of the development process and accelerates development.

Image processing software

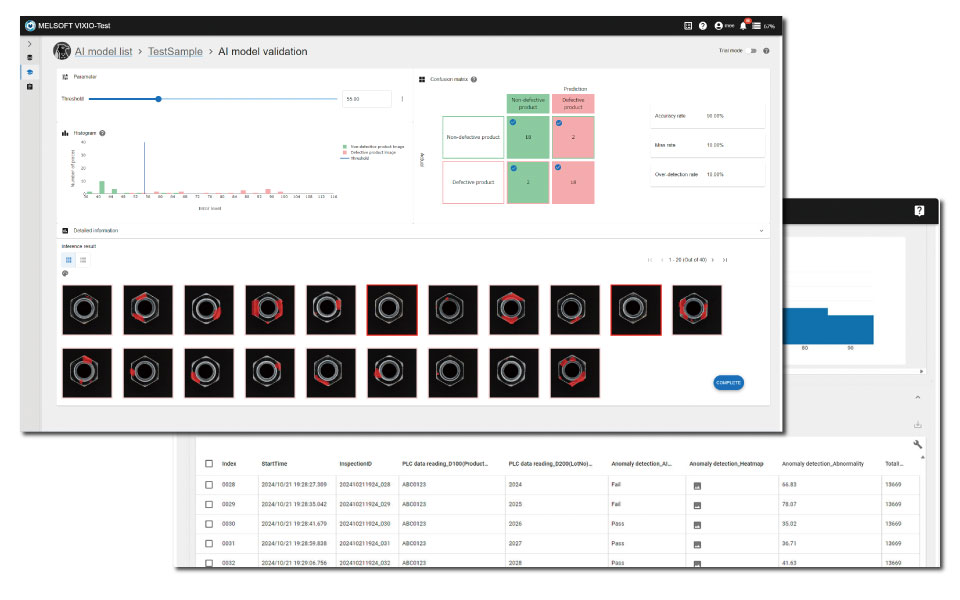

This visual inspection software enables AI utilization without requiring specialized expertise.

It allows you to easily build an AI visual inspection system without programming.

Furthermore, by configuring communication with the MELSEC iQ-R Series or iQ-F Series, AI visual inspection results are automatically linked to data held by the programmable controller, enabling easy traceability.

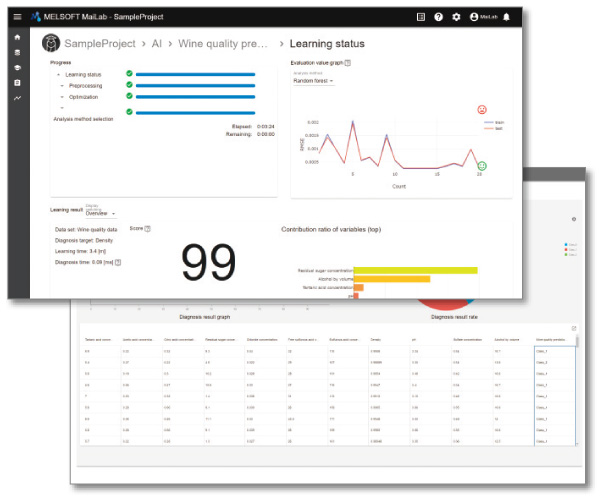

Data analysis software

MELSOFT MaiLab is a data science tool that further improves manufacturing such as predictive maintenance and labor saving by replacing human “intuition” and “experience” with digital technology.

This intuitive tool allows users to easily visualize data, perform offline analysis, and conduct real-time diagnostics without requiring specialized knowledge.