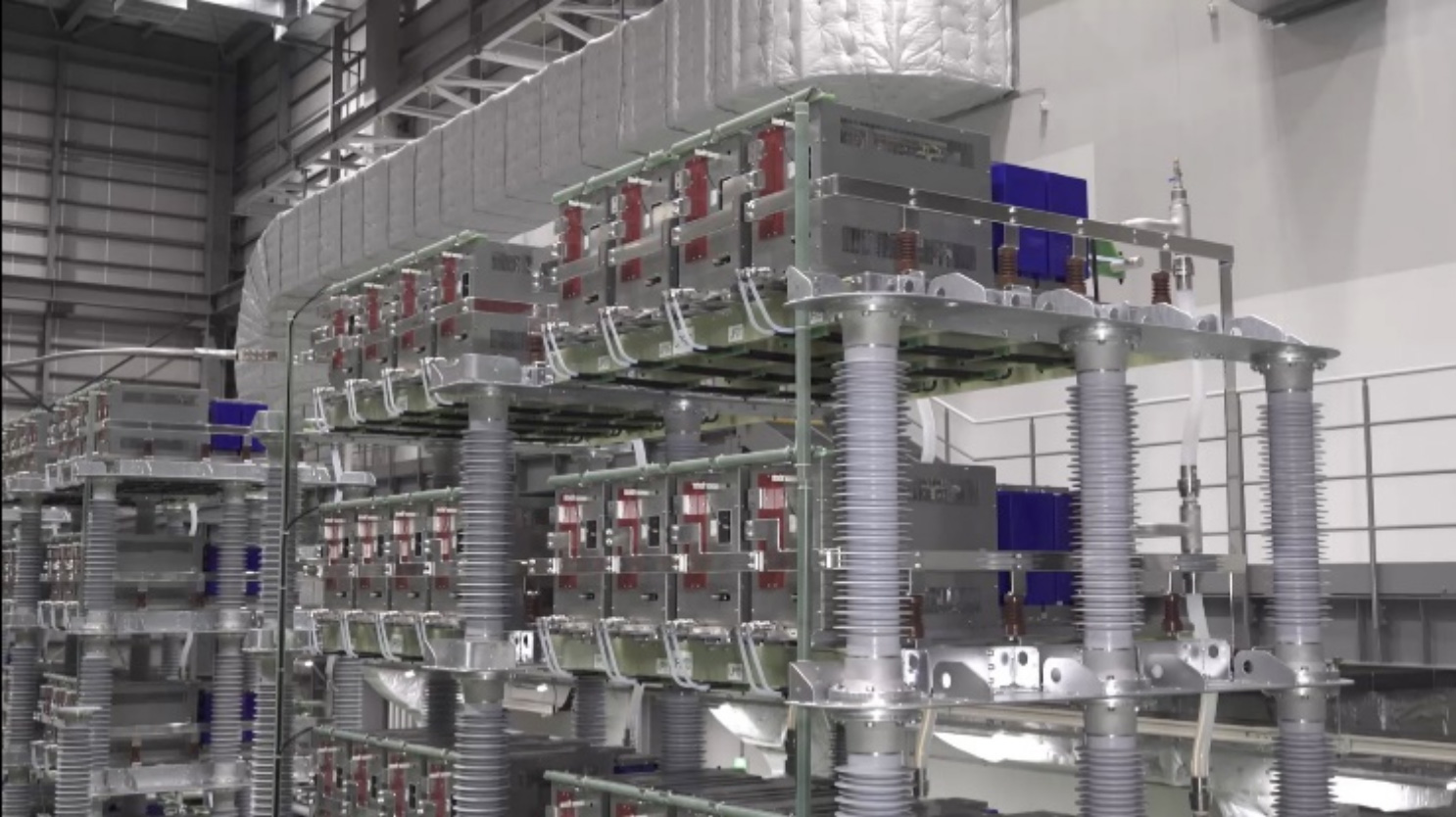

Lineup

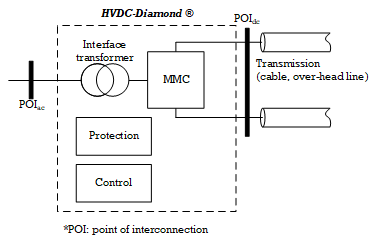

HVDC-Diamond® – Core Technology

Core Technology

The development of Voltage-Source Converters (VSC) based technology represents a key breakthrough for the electric power industry. Compared to conventional Line Commutated Converter (LCC) HVDC technology, VSC-based HVDC systems have faster responsiveness, independent control of active and reactive power, and a more compact physical footprint. These advantages have expanded the market for HVDC technology into new applications, such as integrating offshore wind farms, black starting islanded loads, and supplying passive networks.

Voltage-Source Converter

Voltage-Source Converters (VSC) utilize fully-controllable (self-commutated) power electric devices, meaning they turn have both turn-on and turn-off capability. This ability allows them to produce a fully controllable AC voltage output, in terms of frequency, phase and magnitude. Through this, active and reactive power can independently controlled. This makes them ideal for precise regulation of active power transmission, as well as system voltage support. Additionally, high-frequency switching reduces harmonic output, and typically eliminates the need for filtering; thus, Voltage-Source Converters have a compact footprint. VSC has a fixed DC voltage polarity (unlike LCC, which has a fixed current polarity). This enables fast power reversal and also simplifies the creation of meshed, multi-terminal HVDC grids.

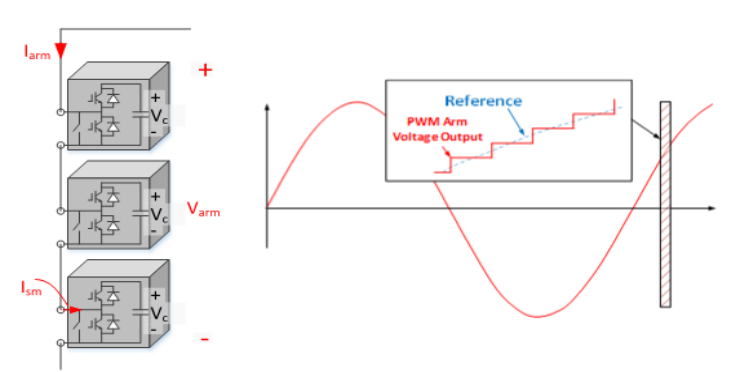

Modular Multi-level Converter (MMC)

Each phase is comprised of upper and lower arms that consist of numerous sub-modules connected in series. The number of series sub-modules required is determined by DC voltage. Through switching combinations of the upper and lower sub-modules by PWM (Pulse Width Modulation), the output waveform is “built” through a large number of precise and small switching steps. This process results in the formation of a near perfect sine wave at the AC side and smooth voltage at the DC side. The resulting configuration has the ability to create an AC waveform without an AC grid connection for reference. Consequently, this enables feeding into passive networks or black start operation.

Sub-module

Series connection of sub-modules gives HVDC-Diamond® flexible scalability for a wide-range

of power capacities.

The sub-modules feature parallel connected IGBTs, increasing its capacity, reducing the total number required and leading to a compact station footprint.

Key components, such as IGBT modules, capacitors, and mechanical bypass switch, are designed and manufactured in Mitsubishi Electric or its subsidiaries, achieving total optimization of the system.

Control and Protection

The control and protection system provides stable and reliable operation through its high-speed hardware platform. Redundant design ensures high availability and reliability. Flexible high-level control software design enables functionality to be tailored to specific power system requirements, for example Fault Ride-Through (FRT) performance.