Lineup

HVDC-Diamond® – Verification Facility

Verification Facility

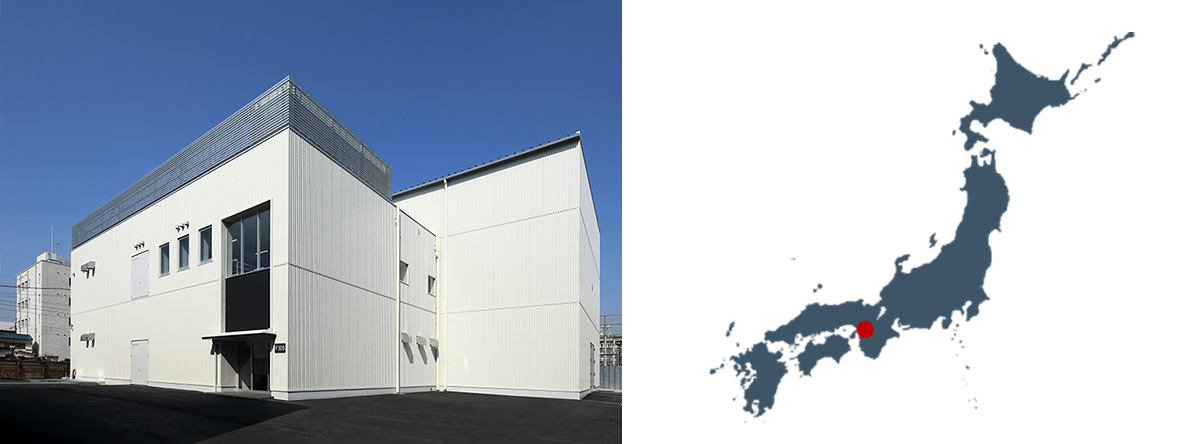

Mitsubishi Electric successfully constructed and commissioned a fully functional back-to-back HVDC facility at its Itami Works near Osaka, Japan. The station was put into service in November 2018, and is available for customer visits.

Purpose

To support future development of HVDC-Diamond® systems and equipment, Mitsubishi Electric has

built a 50 MW verification facility. The facility design and core equipment is the same as

that found in our commercial products, allowing for total system integration to verified

within a controllable and safe operating environment. This enables a wide variety of scenarios

to be tested, which may not otherwise be feasible in an live power system.

The system has been used to verify performance over a series of tests, such as normal

operation, power flow reversal, long-term thermal runs, etc.

System Topology

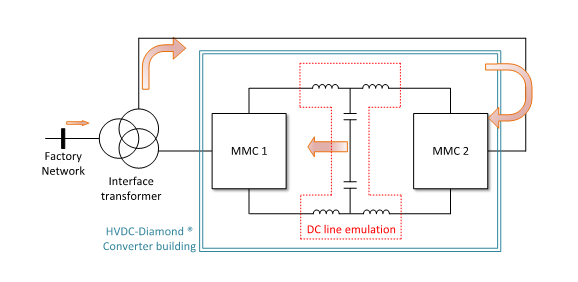

The verification facility has Back-To-Back (BTB) HVDC system comprised of two sets of converters, an interface transformer, AC and DC buses, and auxiliary equipment.

Once both converters are charged from the factory AC Network, the system circulates the active power between primary and secondary windings of the three-winding interface transformer.

Up to 50MW active power is possible, with the factory only supplying system losses.

Technical Highlights

Verification Facility’s major technical parameters are as follows:

| Rating | Value |

|---|---|

| Active Power | 50MW |

| Nominal AC Voltage (Factory Network Side) | 3-Phase 6.6kV (60Hz) |

| Nominal DC Voltage | +/- 21kV |

| DC Current | +/- 1,190A |