SolutionsTotal Maintenance

In today’s dramatically changing business environment, the impact of sudden equipment downtime on corporate profits is enormous, and an increasing number of businesses are implementing planned equipment maintenance with the aim of achieving non-stop factories.

Meanwhile, the manufacturing industry faces another major issue of passing down the expertise of highly experienced employees.

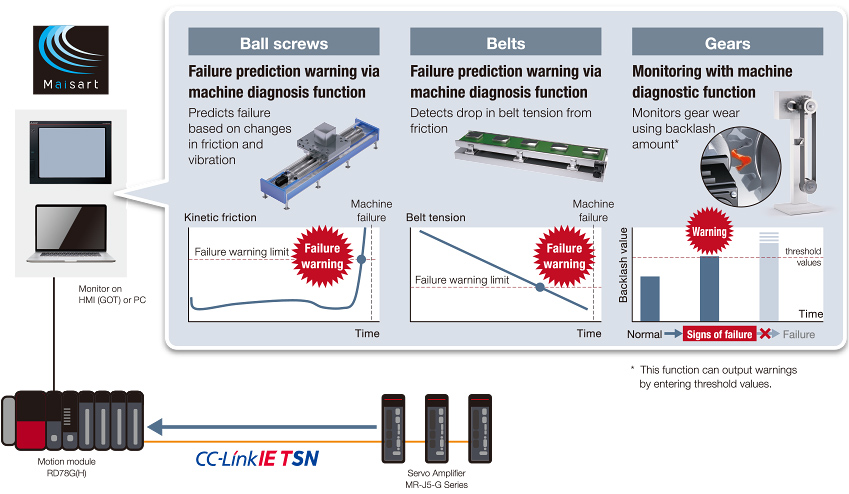

Case05Detecting drive component age-related deterioration (ball screws, belts, gears)

Predictive

Maintenance

Device level

The status of drive component (ball screws, gears, belts) deterioration is unknown, so we can only respond after a failure, which requires considerable labor and cost.

Detect vibration and friction changes to predict the service life of mechanical parts

The future vibration and friction torque of the ball screw (including bearings, guide, etc.) are estimated by Maisart, and a failure warning limit is automatically generated from the estimated information. Failures are predicted by alerting users when the limit is exceeded.

The friction torque of the belt is estimated by Maisart, and any drop in the belt tension is monitored. Failures are predicted by alerting users when the limit is exceeded.

The amount of gear backlash is estimated, and the frictional degradation of the gear is monitored. Failures are predicted by alerting users when the threshold value is exceeded.

Predicting the service life of mechanical parts reduces downtime and maintenance time, as well as improves equipment operating ratio, productivity, and quality.