SolutionsTotal Maintenance

In today’s dramatically changing business environment, the impact of sudden equipment downtime on corporate profits is enormous, and an increasing number of businesses are implementing planned equipment maintenance with the aim of achieving non-stop factories.

Meanwhile, the manufacturing industry faces another major issue of passing down the expertise of highly experienced employees.

Case14Resolving inverter issues smoothly

Corrective

Maintenance

Device level

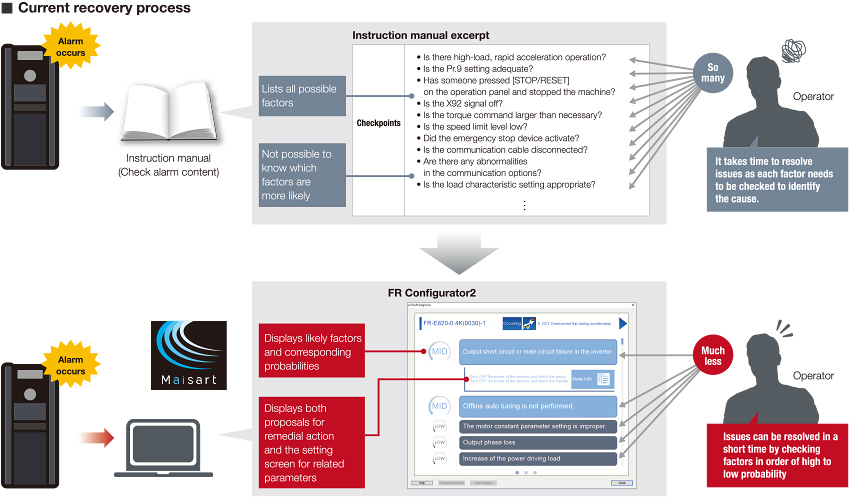

It takes time to resolve issues because checking the cause of inverter alarms one by one in the instruction manual is time consuming.

Support the use of AI inverter troubleshooting

Utilizing the AI alarm diagnostic function installed in the FR Configurator2 inverter setup software, alarm factors can be checked in order of most likely to least likely.

Achieve easy and quick troubleshooting that reduces downtime.