SolutionsTotal Maintenance

In today’s dramatically changing business environment, the impact of sudden equipment downtime on corporate profits is enormous, and an increasing number of businesses are implementing planned equipment maintenance with the aim of achieving non-stop factories.

Meanwhile, the manufacturing industry faces another major issue of passing down the expertise of highly experienced employees.

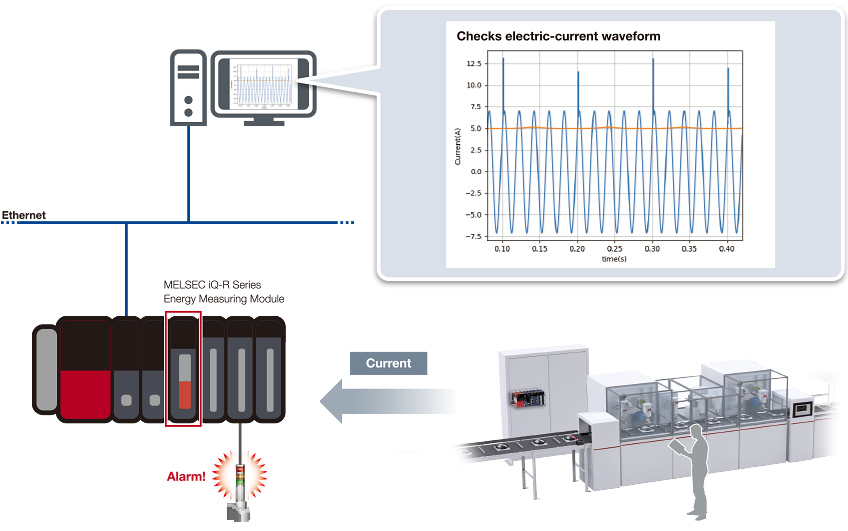

Case06Preventing the sudden failure of old equipment

Predictive

Maintenance

Equipment level

Sudden failures of equipment used for a long time results in unnecessary labor and costs.

Plan for equipment maintenance by monitoring current waveforms

The in-rush current waveform of equipment at the time of initial operation is measured in a short cycle of 10 ms to monitor any changes in electric-current waveform.

By detecting equipment failure in advance through short cycle measurement, maintenance planning is possible and labor costs are greatly reduced.