Lineup

Medium-voltage Switchgear

Retrofit Vacuum Circuit Breakers for Replacement of Existing Gas Circuit Breakers Type GV

Retrofit VCBs* for Replacement of Existing GCB*(10-SFG-40)

Type: 10-VPR-40D(GV)

*VCB : Vacuum Circuit Breaker

*GCB : Gas Circuit Breaker

Retrofitting VCB for GCB

Recommendation to replace the existing GCBs with new VCBs in order to ensure the safe and reliable operation of your switchgear.

Features of Retrofit VCB

Outstanding reliability

- The highly reliable operating mechanism is incorporated in the Retrofit VCB. This operating mechanism is used in Mitsubishi’s latest VCBs.

- Self-cooling VCBs that do not require a fan to be mounted on the panel. Available in a wide range, from rated current of 1,250 to 3,150A.

- Compliant with IEC 62271-100-2012 and has passed type tests for classes M2, E1 and C2, which represent the highest levels of quality.

Saving running cost

- By application of VCB, no need to treat the SF6 gas and to carry out the overhaul with dismantle work for inspection and cleaning inside of the tank.

- The mechanical parts are coated with a long-life grease that contributes to the prevention of oxidation degradation and oilless bearings has been adopted for the bearing section of latch, thus extending the lubrication cycle to mechanical parts from three to six years and reducing the time required for maintenance.

Environmental friendly

- No use of SF6 gas of having high global warming potential.

- No use of the six hazardous substances (mercury, cadmium, lead, hexavalent chromium, PBB and PBDE), a measure that exceeds the requirements of RoHS standards. One example is use of a rust-proofing treatment for small parts such as pins and screws that is free of hexavalent chromium, a substance known to contaminate soil.

Saving replacement work

- Interface with the existing panel between GCB and Retrofit VCB is same.

- No modification is required.⇒No need long shutdown.

Ratings

| Type | 10-VPR-40D(GV) | |||

|---|---|---|---|---|

| CR suppressor(*1) for sub code name C,L(*2) | mounted | none | ||

| CR suppressor(*1) for sub code name S(*2) | none | |||

| Closing operating mechanism | Motor-spring charged mechanism | |||

| Standards(*3) | IEC62271-100- 2012 | |||

| Rated voltage (kV) | 12 | |||

| Rated normal current (A) |

1,250 | 1,250 | 2,000 | 3,150 |

| Rated normal current(A) In the case of ambient temperature 50℃ | 1,000 | 1,000 | 1,600 | 2,700 |

| Rated frequency (Hz) | 50/60 | |||

| Rated short-circuit breaking current (kA) | 40 | |||

| Rated short-circuit Making current (kA) (Peak) | 104 | |||

| Rated short-time withstand current (kA) | 40 (3s) | |||

| Rated opening time (s) | 0.03 | |||

| Rated breaking time (cycles) | 3 | |||

| Rated withstand voltage (kV) Power frequency | 28 | 36 | ||

| Rated withstand voltage (kV) Lightning impulse | 75 | 95 | ||

| Type test class(*4) Mechanical | M2 | |||

| Type test class(*4) Electrical | E1 | |||

| Type test class(*4) Small capacitive current switching | C2 | |||

| Rated operating sequence | O-3min-CO-3min-CO CO-15s-CO O-0.3s-CO-1min-CO |

|||

| No-load closing time(s) | 0.1 | |||

| Closing operating/control current (A)(*5) Motor | 1.2 (motor charging time: 6s) | |||

| Closing operating/control current (A)(*5) Control current (Closing coil) | 3.5 | |||

| Tripping device | Shunt tripping coil (STC) | |||

| Opening control current (A) (STC coil)(*5) | 4 | |||

| Auxiliary switch | 5a5b | |||

| Operating counter (Mechanical) | Standard equipment | |||

| Mass (kg) for sub code name C,L(*2) | 250 | 225 | 265 | 370 |

| Mass (kg) for sub code name S(*2) | - | 225 | 255 | 350 |

| Type of interchangeable GCB | 10-SFG-40 | |||

- *1 CR suppressor is a device to absorb the surge generated by switching.

- *2 Sub code name C : mounted CR suppressor for power stations.

Sub code name L : none CR suppressor for power stations.

Sub code name S : none CR suppressor for transformer substations . - *3 IEC : International standards, IEC 62271-100-2012.

- *4 Type test class described in IEC 62271-100-2012.

- *5 Closing operation/control current and opening control current show the value of 110V DC.

VCB & GCB Comparison

Comparison of Life of VCB & GCB

| Unit | Item | Retrofit VCB | GCB |

|---|---|---|---|

| Mechanical life | Number of operations | 10,000 times | |

| Electrical life | Short circuit breaking | 30 times | 10 times |

| Load current breaking | 10,000 times | ||

| Small current (less than 100 A) breaking | 10,000 times | 3,000 times | |

| Life of whole circuit breaker | Number of operations | 10,000 times | |

- NOTE : The above switching number of time is the actual capacity checked in the short-term continuous switching test, and does not guarantee the life for a long period of time.

- NOTE : Perform the maintenance and inspection according to the standard of the inspection manual to keep the service life.

Comparison of Scheduled Maintenance

| Periodic Inspection | Retrofit VCB | GCB |

|---|---|---|

| General inspection (Every 3 years) | Man-hours: 2 Hr × 2 men | Man-hours: 4 Hr × 2 men |

| ・Visual check and cleaning ・Check of insulation resistance ・Lubrication of primary junctions |

・Visual check and cleaning ・Check of insulation resistance ・Lubrication of mechanism, primary junctions ・Operation Test |

|

| Detailed inspection (Every 6 years) | Man-hours: 5 Hr × 2 men | Man-hours: 10 Hr × 2 men |

| ・Check of vacuum pressure ・Lubrication of mechanism ・Operation test |

・Inspection and adjustment of Breaking part ・Operation test |

|

| Replacement of breaking part | When the number of operations exceeds the values below, the VI should be replaced. | When the number of operations exceeds the values below, main contacts and arcing contacts should be replaced. |

| ・Load current: 10,000 times (replacement of entire VCB) ・Short-circuit current: 30 times |

・Load current: 1,000 times ・Short-circuit current 10 times |

Comparison of Structure

| Unit or Part | Retrofit VCB | GCB |

|---|---|---|

| Control circuit | Same as GCB | Stored energy motor operation |

| Interlocking | When moving CB inside panel, closing operation cannot be performed. When CB is closed, it cannot be moved inside panel. | |

| Insulation | Epoxy-resin molding for main conductors and BMC (Bulk Mold Compound) for separation of VI's. | Epoxy-resin molding Insulation by SF6 |

| Drawout mechanism | Same as GCB | Withdrawn by pulling of handle. |

| Truck | Position switch, automatic safety shutters. | |

| Primary junction | Tulip type connector, self-coupling. | |

| Secondary junction | Manual-coupling | |

| Ext. aux-switch | Mechanically linked operating mechanism. |

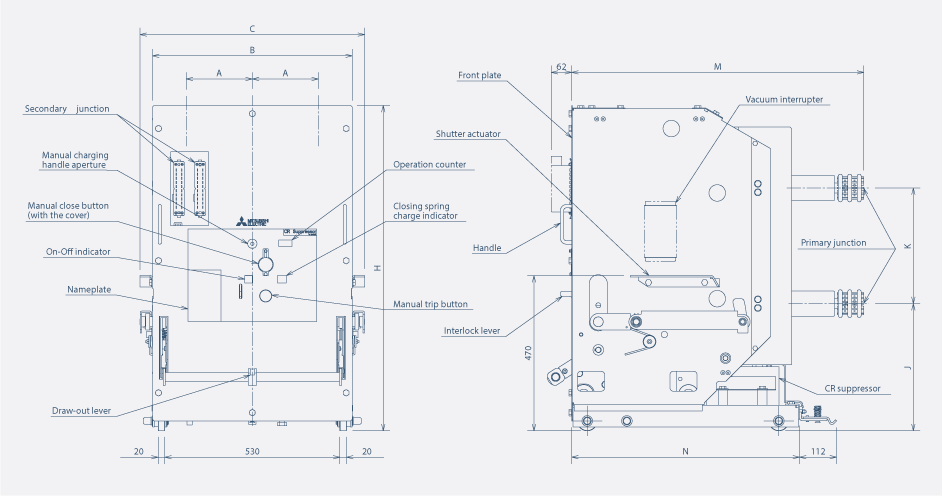

Outline and Dimensions

Dimensions

| Rated normal current(A) | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | H | J | K | M | N | |||

| common | for sub code C, L | for sub code S | for sub code C, L | for sub code S | ||||||

| 1,250/2,000 | 200 | 605 | 680 | 985 | 385 | 350 | 883 | 783 | 689 | 589 |

| 3,150 | 250 | 755 | 830 | 1040 | 400 | 400 | ||||

If consider using this retrofit VCB, please contact us to confirm any interference with the

existing Switchgear.

In that case, please inform the serial number of the existing GCB and existing Switchgear.