- Research & Development

- Automotive Equipment

FOR IMMEDIATE RELEASE No. 3342

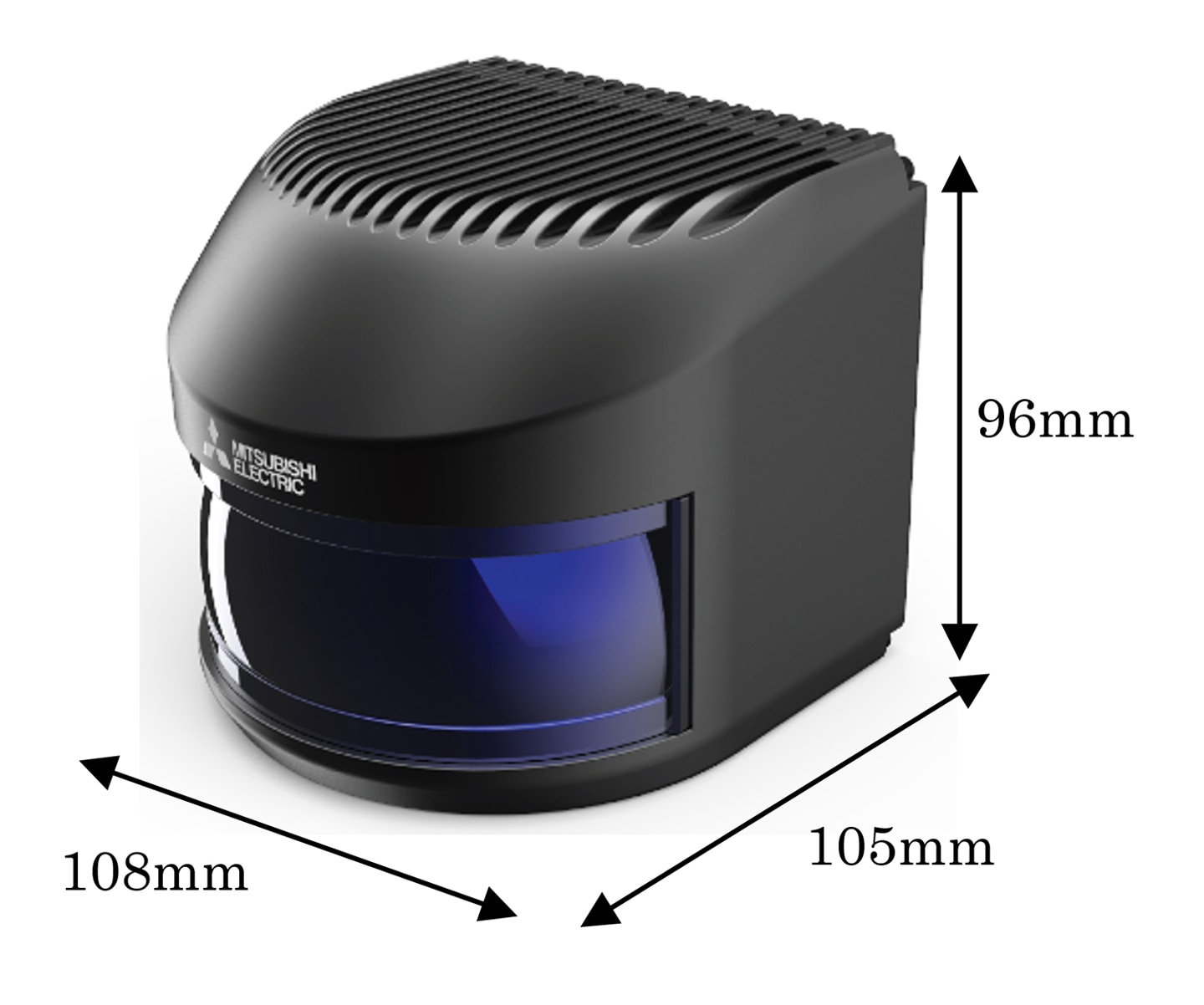

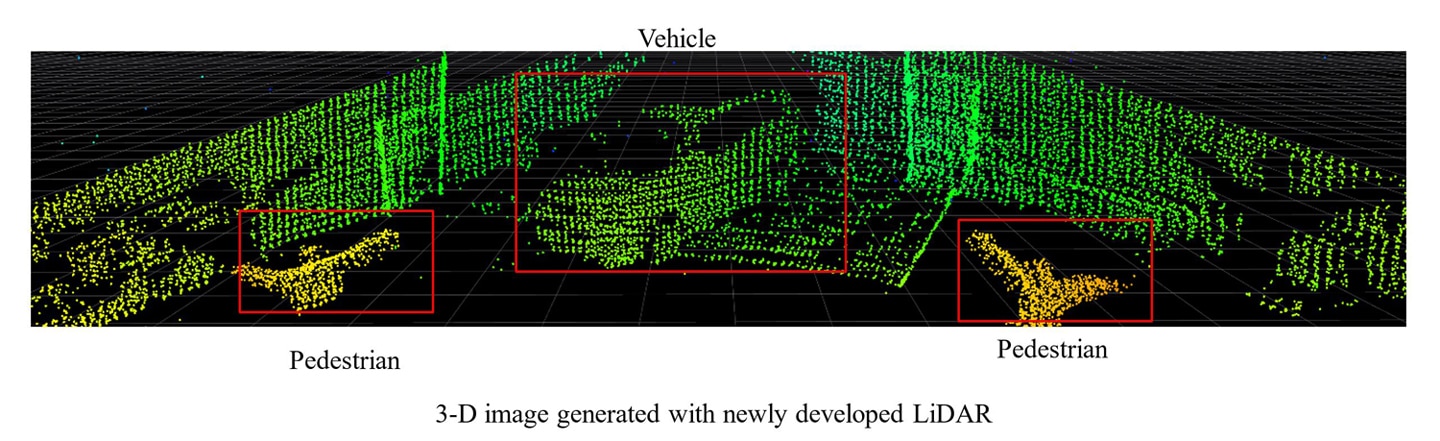

TOKYO, March 12, 2020 - Mitsubishi Electric Corporation (TOKYO: 6503) announced today that it has developed a compact light-detection and ranging (LiDAR) solution incorporating a micro-electromechanical system (MEMS) that achieves an extra-wide horizontal scanning angle to accurately detect the shapes and distances of objects ahead in autonomous driving systems. The new LiDAR solution irradiates objects by laser and uses a dual-axis (horizontal and vertical) MEMS mirror to scan for the reflected light, generating three-dimensional images of vehicles and pedestrians. Mitsubishi Electric expects this compact, low-cost solution to contribute to the realization of safe, secure autonomous driving.

-

MEMS LiDAR

-

Key Features

- 1)Large dual-axis electromagnetic mirror with unique lightweight design enabling wide scanning angle

After objects are irradiated by laser, the maximum amount of reflected light must be collected in order to obtain the most precise three-dimensional images, particularly of vehicles and pedestrians. LiDAR systems therefore require mirrors with a large surface area in order to maximize light collection. Additionally, a wide scanning angle is required for accurate vehicle periphery monitoring. Mitsubishi Electric's new development incorporates the industry's largest electromagnetic MEMS mirror, measuring 7mm by 5mm, in a lightweight design which is able to scan horizontally and vertically. Despite its size, the unique structure of the MEMS mirror facilitates a reduction in weight without sacrificing rigidity. The lightweight design and high electromagnetically generated driving force allows the mirror to achieve large horizontal movement of ±15 degrees. Vertical movement is currently ±3.4 degrees, and Mitsubishi Electric aims to increase this to ±6.0 degrees or more by improving the beam structure of the MEMS.

The MEMS mirror can be produced in large quantities on a silicon substrate using semiconductor-processing technology, making it suitable for mass production. In addition, it uses fewer parts compared to mirrors driven mechanically with motors, which will contribute to the durability of the LiDAR solution.

- 2)Optimized design supports downsizing as well as acquisition of 3-D images over wide area

Mitsubishi Electric has optimized the arrangement of the electromagnetic MEMS mirror and optical components—including multiple laser light sources, photodetectors and lenses—to suppress optical vignetting and to avoid the laser beam being distorted by any of the LiDAR's internal components. The optimized design and optical transmission/reception mechanism achieve an extra-wide horizontal scanning angle, enhancing the scanning of vehicles ahead or oncoming vehicles, pedestrians crossing the road, traffic lights, traffic signs, and roadside obstacles. With continued development, Mitsubishi Electric aims to achieve a vertical scanning angle exceeding 25 degrees, which will allow the detection of vehicles and pedestrians even in close proximity.

The LiDAR body has a volume of just 900 cc owing to optimal arrangement of the signal processing circuitry, power supply circuit and optical transmission/reception mechanism. Going forward, Mitsubishi Electric is targeting development of an extra-small unit with a volume of just 350 cc or less.

Inquiry

Media contact

Customer Inquiries

Related articles

- Research & Development

-

Apr 24, 2025

-

Mar 27, 2025

-

Mar 13, 2025

- Automotive Equipment

-

Apr 24, 2025

-

Dec 23, 2024

-

Nov 25, 2024