- Factory Automation Systems

FOR IMMEDIATE RELEASE No. 3412

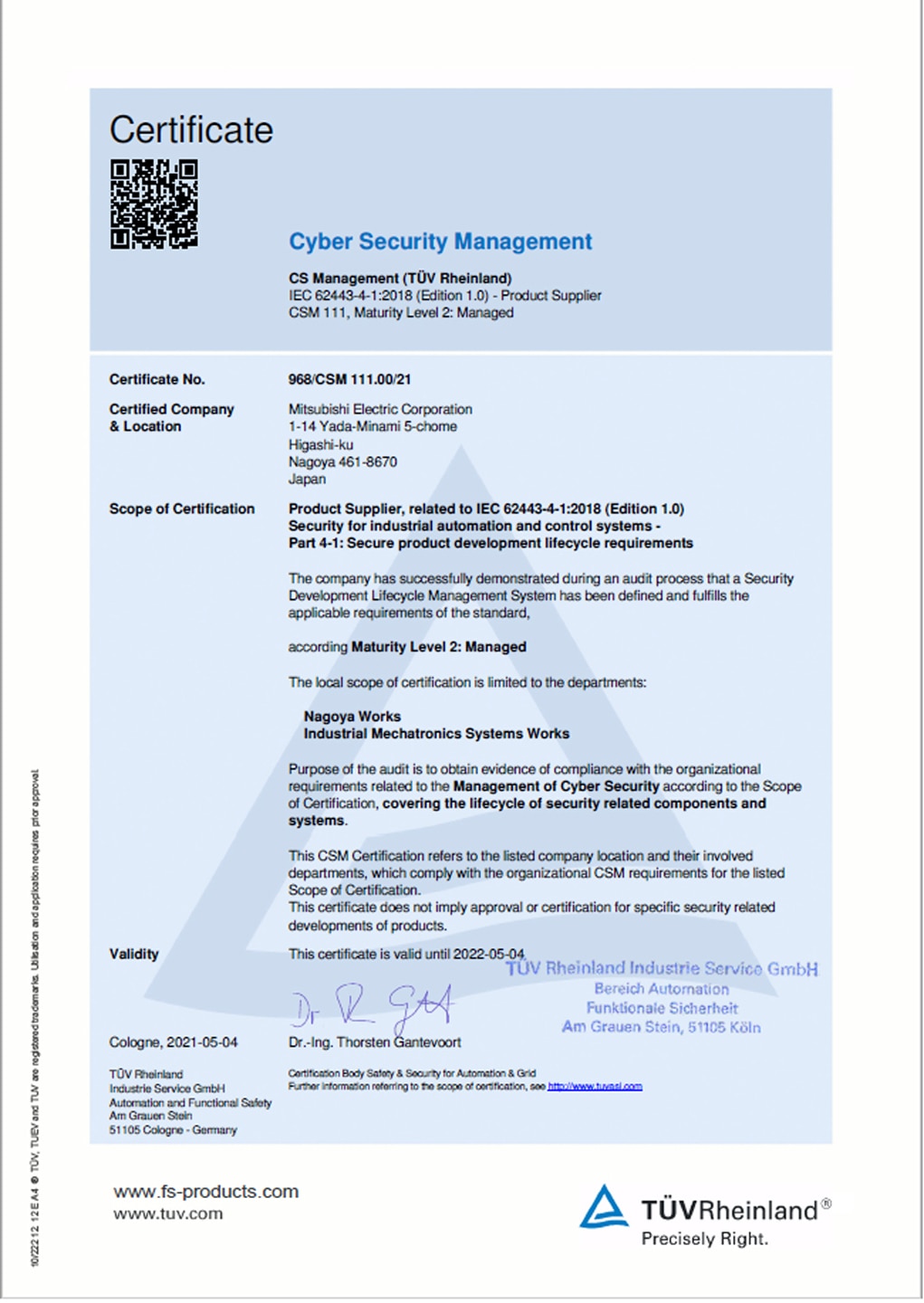

TOKYO, May 25, 2021 - Mitsubishi Electric Corporation (TOKYO: 6503) announced today that its Nagoya Works and Industrial Mechatronics Systems Works, both engaged in the development and manufacture of industrial automation in Nagoya, Aichi Prefecture, have each obtained a certification under the International Electrotechnical Commission's IEC 62443-4-1 standard regarding the Security Development Lifecycle (SDL) of industrial automation and control systems. The two newly certified Works are now deploying SDL practices to satisfy customer needs for safe and secure solutions for factory automation and industrial-mechatronics products, such as programmable controllers, industrial PCs, FA sensors, human-machine interfaces, servo amplifiers, inverters, robots, CNCs, electrical discharge machines, laser processing machines and related software and services.

In recent years, the increased use of IoT technologies, especially in manufacturing, has also brought increased cybersecurity risks, which can manifest themselves as unscheduled production stops, loss of confidential information and even potential cases of injuries to operators and production plant. This certification, awarded by one of the world's leading third-party inspection agencies, German-based TÜV Rheinland, recognizes that Mitsubishi Electric's two facilities comply with international security requirements for entire lifecycles, including product development, production, and maintenance. Additionally, to help customers confidently implement their industrial automation initiatives, Mitsubishi Electric is utilizing SDL best-practice in its integrated e-F@ctory solutions, which combine factory-automation and IT technologies to reduce the total costs of factory-automation development, production and maintenance.

-

Certificate

-

Nagoya Works

-

Industrial Mechatronics Systems Works

About e-F@ctory

e-F@ctory is Mitsubishi Electric's integrated concept to build reliable and flexible manufacturing systems that enable users to achieve many of their high speed, information driven manufacturing aspirations. Through its partner solution activity, the e-F@ctory Alliance, and its work with open network associations such as The CC-Link Partners Association (CLPA), users can build comprehensive solutions based on a wide ranging "best in class" principle. In summary, e-F@ctory and the e-F@ctory Alliance enable customers to achieve integrated manufacturing but still retain the ability to choose the most optimal suppliers and solutions.

e-F@ctory is a registered trademark of Mitsubishi Electric Corporation.

Inquiry

Media contact

Customer Inquiries

Related articles

- Factory Automation Systems