Journals

2025.02.25

The Real Strength of Power Semiconductors Supporting a Carbon-neutral World

- #Focus

- #Business

- #Interview

- #Sustainability

- #Society

- #Social contribution

- #Factory

- #Innovation

- #Semiconductors

- Home

- Our Stories

- Article list

- The Real Strength of Power Semiconductors Supporting a Carbon-neutral World

Semiconductors were once one of Japan's most glorified industries. Now, power semiconductors have arisen to take over that star status. Among these, power semiconductors made from SiC (silicon carbide) are able to drastically reduce power loss and as such play an important role in a variety of areas, including railway, automotive, renewable energy, and home appliances. They are garnering attention as the key device in order to achieve Japan's goal of a carbon neutral society by 2050.

Contents

- Power semiconductors are the key to restoring Japan's semiconductor industry

- What are power semiconductors anyway?

- We all use power semiconductors everyday

- Strengths of Mitsubishi Electric's power semiconductors

- SiC (silicon carbide) as an alternative power semiconductor material to Si (silicon)

- SiC power semiconductors promising to be a driving force for GX

Power semiconductors are the key to restoring Japan's semiconductor industry

Japan's semiconductor industry began in the 1950s. By the 1980s, the country's reputation for manufacturing semiconductors had become firmly established all around the world, however, the industry began taking a downward dive with the 1986 Arrangement between the Government of Japan and Government of the United States of America concerning Trade in Semiconductor Products, and has been stagnant since the 2000s. Meanwhile, with the COVID-19 pandemic, unstable world affairs and other factors having an impact, economic security risk is high. In order to keep up with rapid digitalization and carbon-neutral goals, the importance of semiconductors and information processing technology is greater than ever.

Semiconductors play a crucial role in digitalization and information technology. As such, in May 2022 the Japanese government added semiconductors to the list of designated Specified Critical Products in the Economic Security Promotion Bill. This list comprises a total of 11 items which have been designated as key to economic security. Regarding semiconductors, the Ministry of Economy, Trade and Industry (METI) allocated 368.6 billion yen in the second supplementary budget for FY2022, and in the supplementary budget for FY2023, 1,545 billion yen was allocated for subsidies to boost semiconductor production capacity. In other words, nearly 2 trillion yen has been injected in the semiconductor industry over the past two years.

Koichiro Noguchi

Koichiro NoguchiDoctor of Engineering

General Manager, Product Strategy Dept., Power Device Works, Mitsubishi Electric Corporation

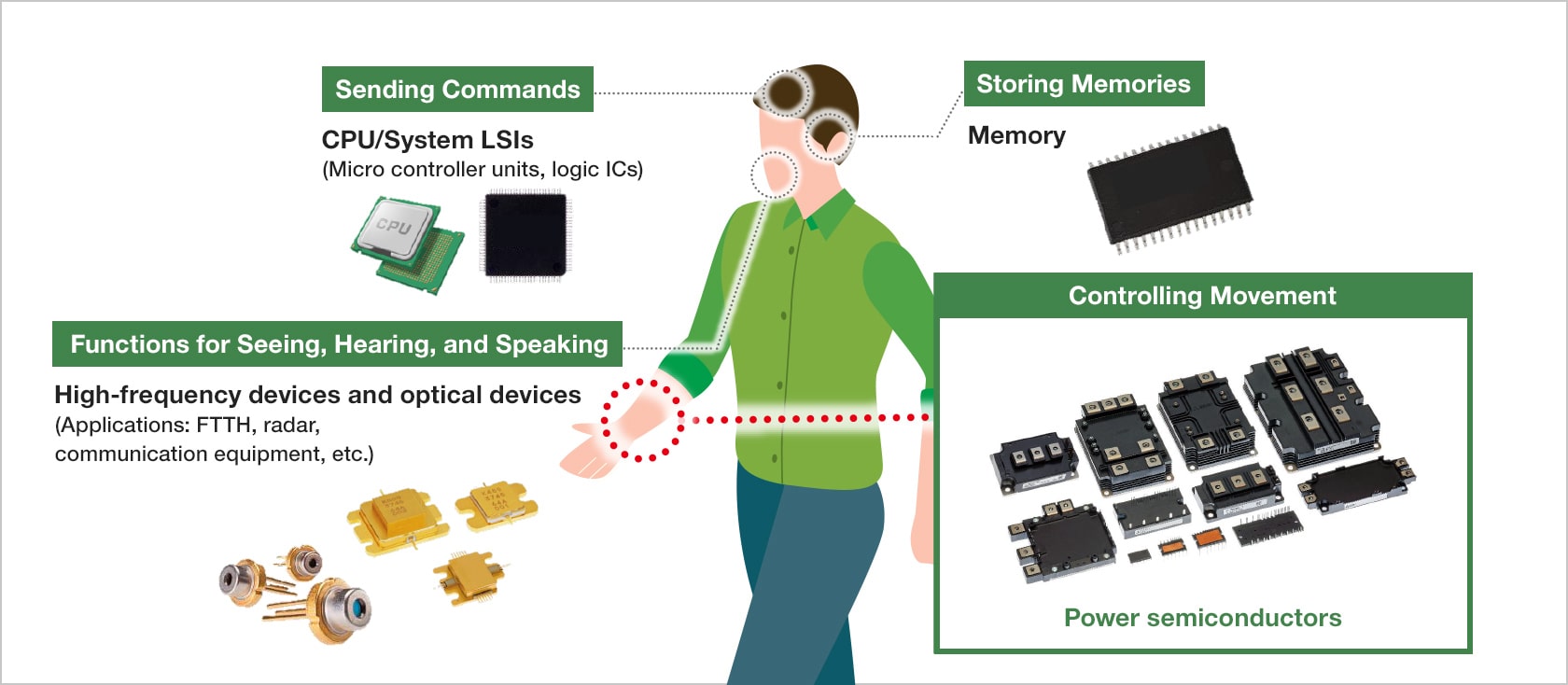

Semiconductors include the widely-known microcontrollers, memories, and so on, but one device garnering attention as the key to realizing a carbon-neutral society and restoring Japan's semiconductor industry is the "power semiconductor." In the power semiconductor market, Japan is one of the three major players along with the U.S. and Europe, with a global market share of around 26%, therefore its presence is certainly not small.

Incidentally, Mitsubishi Electric remains the top Japanese company, accounting for about 30% of the abovementioned approximately 26% (METI's "Semiconductor and Digital Industry Strategy" June 2023). In light of this fact, we spoke with Mr. Koichiro Noguchi of Mitsubishi Electric Power Device Works about these "power semiconductors" that are the focus of so much attention.

What are power semiconductors anyway?

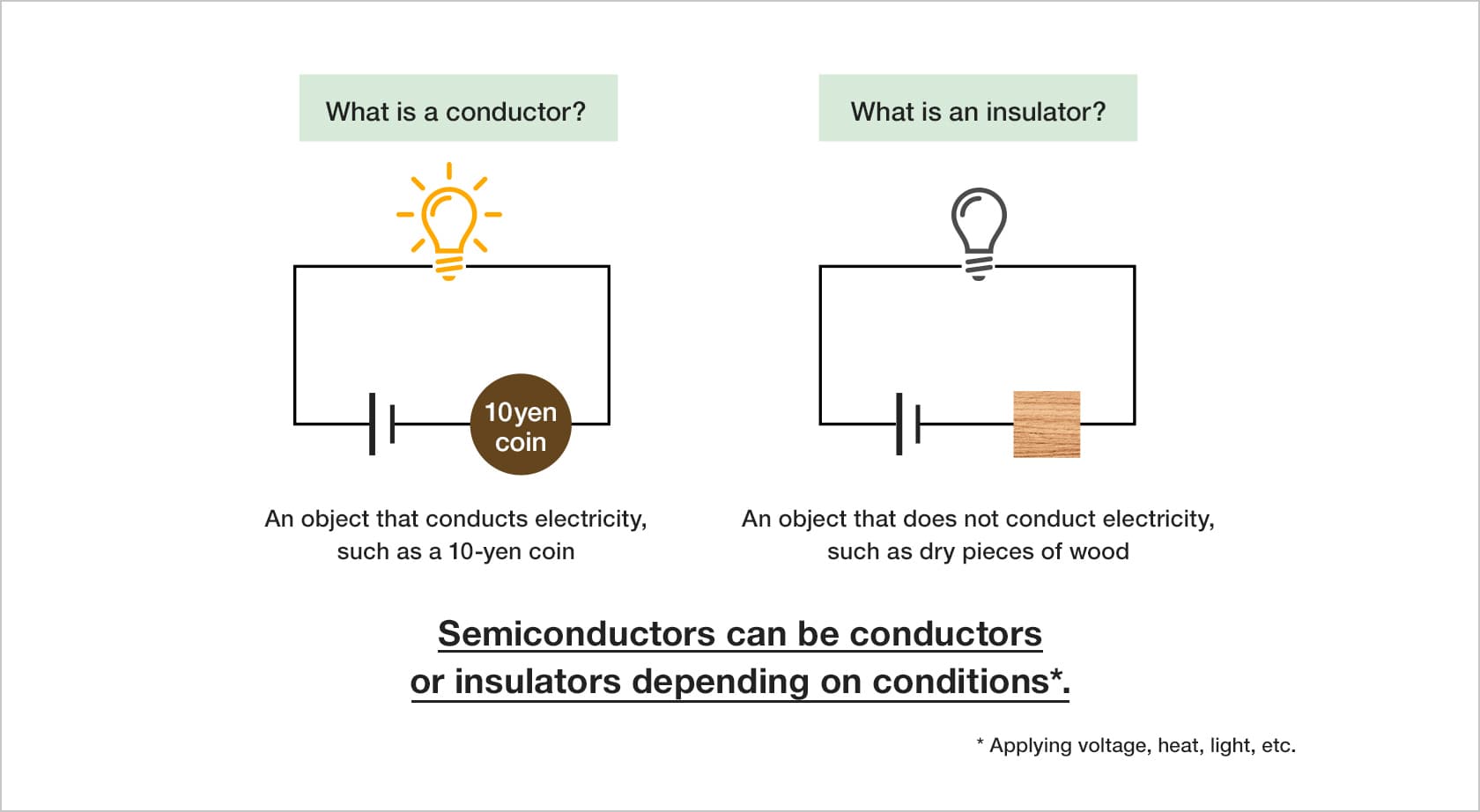

There are two types of materials: conductors, which conduct electricity, such as metals, and insulators, which do not conduct electricity, such as rubber and wood. A "semiconductor" is a material that either conducts or does not conduct electricity depending on conditions such as the application of voltage, light, or heat.

Noguchi: Put simply, a semiconductor is a switch that starts and stops the flow of electric current. A power semiconductor starts and stops current as "energy." By contrast, semiconductors such as microcontrollers and memories start and stop current as "signals." That's the difference. They are also different in terms of functions. The objective of a memory device is to think, remember, and so on, just like a human brain. On the other hand, a power semiconductor is like a human's arms and legs and is used to control movement.

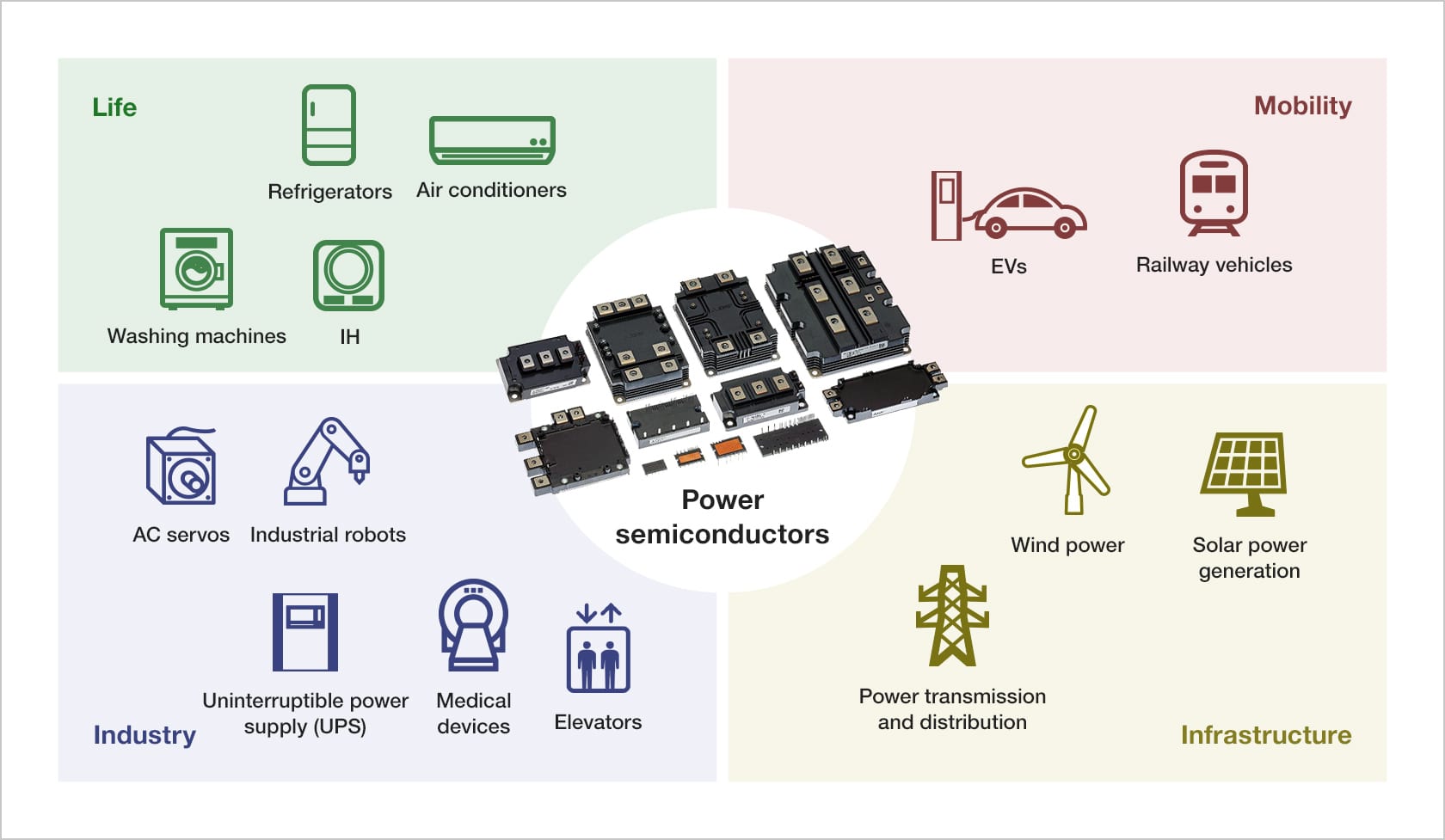

We all use power semiconductors everyday

Power semiconductors are used in many everyday things, including household appliances such as air conditioners and refrigerators, as well as railway vehicles, hybrid/electric vehicles, and elevators. They are also used in places we don't often see, such as industrial robots used in factories, medical devices, solar and wind power generation, and power distribution equipment.

Noguchi: Out of all home appliances, air conditioners have the highest energy consumption, and most air conditioners are equipped with up to three modules*1 containing power semiconductors. Mitsubishi Electric is particularly skilled in manufacturing power modules for air conditioners and equip these not only in our in-house made air conditioners, but also many air conditioners made by other manufacturers. Mitsubishi Electric's power modules are even adopted in many other home appliances including refrigerators and washing machines, and we actually have the world's largest share of power modules in home appliances*2.

- *1A module is a power semiconductor that combines multiple power semiconductors into a single package.

- *2FY2021 results, based on Mitsubishi Electric's research

Mitsubishi Electric's power semiconductors are also very compatible with vehicles. For example, the first power semiconductor to be equipped in a Japanese-made hybrid car was manufactured by Mitsubishi Electric. Since then, the company's power semiconductors have been equipped in other hybrid and electric vehicles (EVs).

Noguchi: Engines of gasoline-driven cars run by burning fossil fuel, however hybrid and electric vehicles rotate a motor with electricity to make up part of the engine's power. Power semiconductors are crucial to rotating these motors.

Also, there are two main usages for power semiconductors in railway vehicles. The first is to operate the motor, just in the same way as for EVs. The second is in a device that supplies power for the railway car's air conditioning, lighting and so on. Power brought into the car from the power lines need to be converted to a voltage and frequency suited to actual use, and power semiconductors are used to perform this conversion. Mitsubishi Electric has worked on many railway vehicles in Japan and our power semiconductors are used in these.

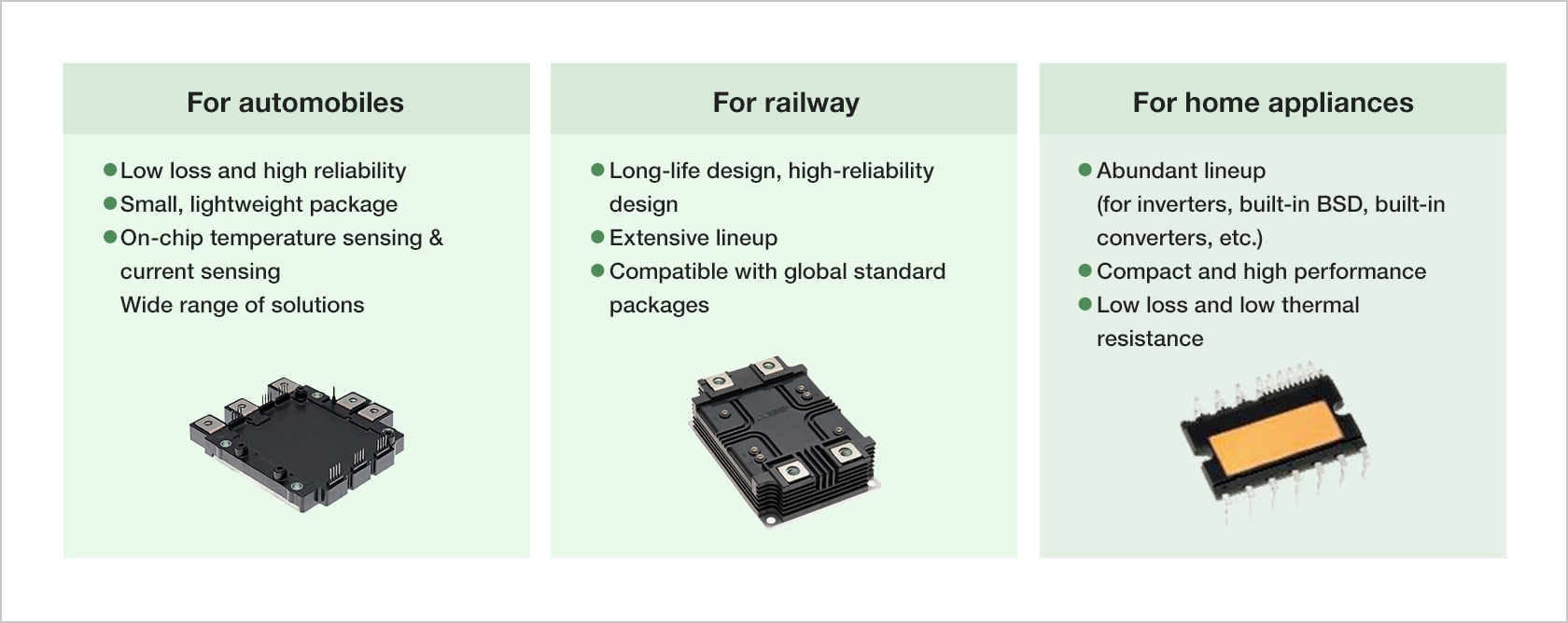

Strengths of Mitsubishi Electric's power semiconductors

Mitsubishi Electric first began developing power semiconductors in the 1950s. In 1958, the company developed Japan's first semiconductor for power (i.e. power semiconductor), therefore it has a long history of equipping semiconductors in electric engines and is today known as one of the leading power semiconductor companies.

Mr. Noguchi is holding a powermodule for air conditioners in his hand. In front of him on the table is a power module equipped in industrial machinery.

Mr. Noguchi is holding a powermodule for air conditioners in his hand. In front of him on the table is a power module equipped in industrial machinery.

Noguchi: Mitsubishi Electric's power semiconductors are used in a wide variety of power electronics equipment, including air conditioners, railway vehicles, EVs, and industrial robots used in factories. When we develop a power semiconductor, we have in-depth discussions with our customers to decide the characteristics and functions to best suit each customer's specific equipment then incorporate these into the performance of the power module. We have engaged in the process for many years now and I believe that's why our power modules are easy to use.

SiC (silicon carbide) as an alternative power semiconductor material to Si (silicon)

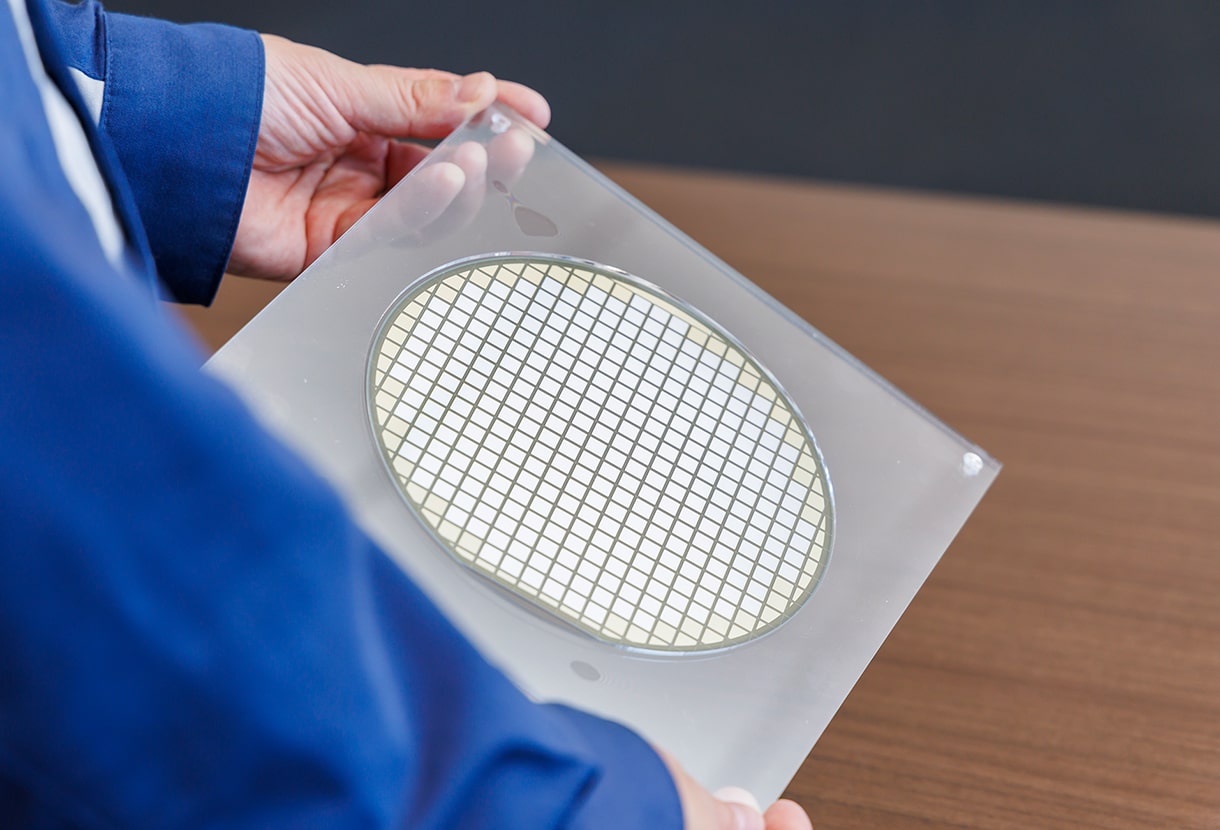

In power modules, semiconductor chips are fabricated on a thin, flat disc called a wafer, multiple chips are fitted, metal wires are attached, and then everything is packaged and sold as a single module. Currently, most wafers are made of Si (silicon), but power semiconductors use a material called SiC (silicon carbide).

SiC power semiconductor wafer

SiC power semiconductor wafer

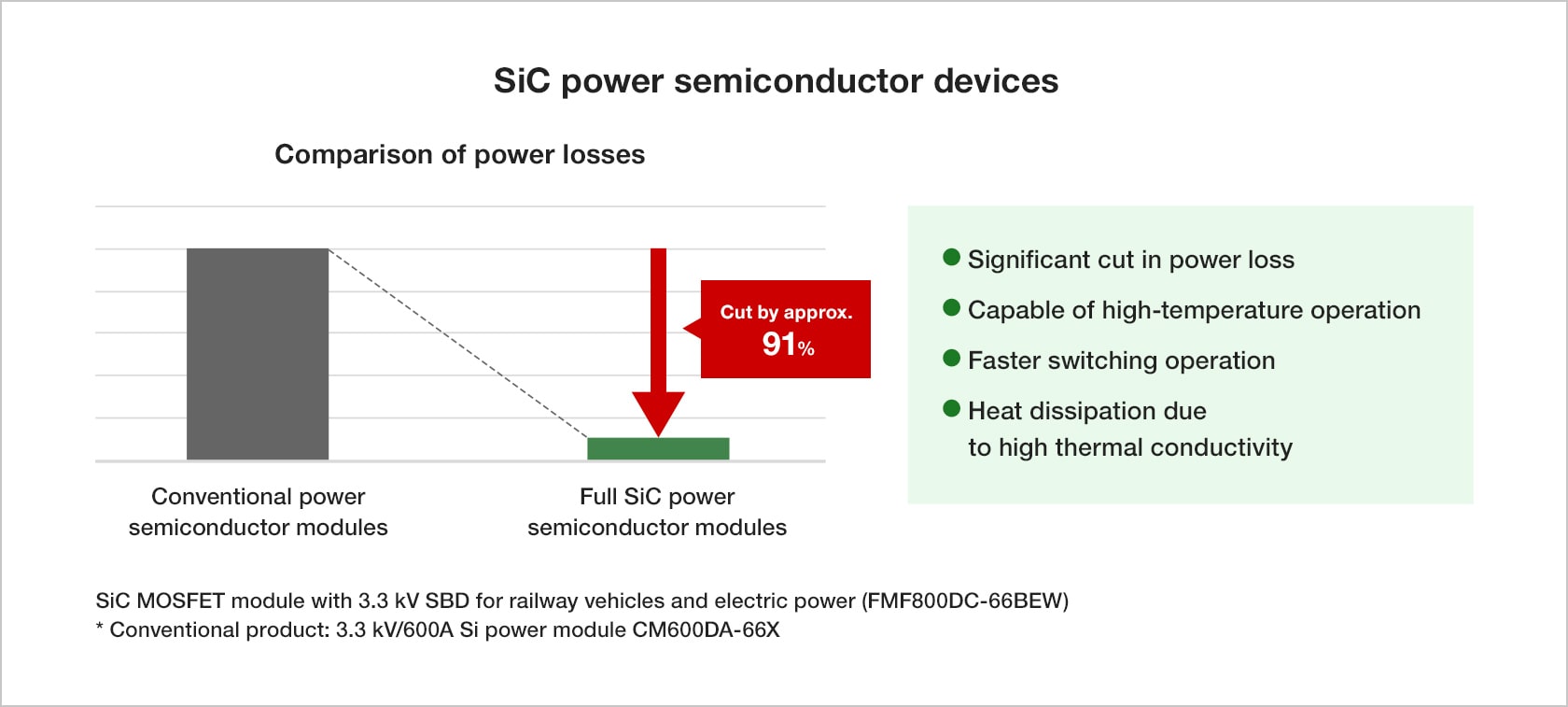

Noguchi: Earlier I introduced power semiconductors as being like a switch to operate energy and in order to make it easier to send energy back and forth via this switch it is impossible to avoid energy loss upon switch operation (called "switching"). However, if we change the semiconductor wafer material from silicon to SiC, we can reduce energy loss at switching by up to around 90%*3 due to the characteristics of this material. Moreover, by making switching faster to improve the performance of the motor that power semiconductors rotate, we anticipate a reduction of motor energy loss which, in other words, means further energy-saving.

- *3SiC-MOSFET module with built-in SBD "FMF800DC-66BEW." Compared with Si power module "CM600DA-66X."

Mitsubishi Electric's SiC power module

Mitsubishi Electric's SiC power module

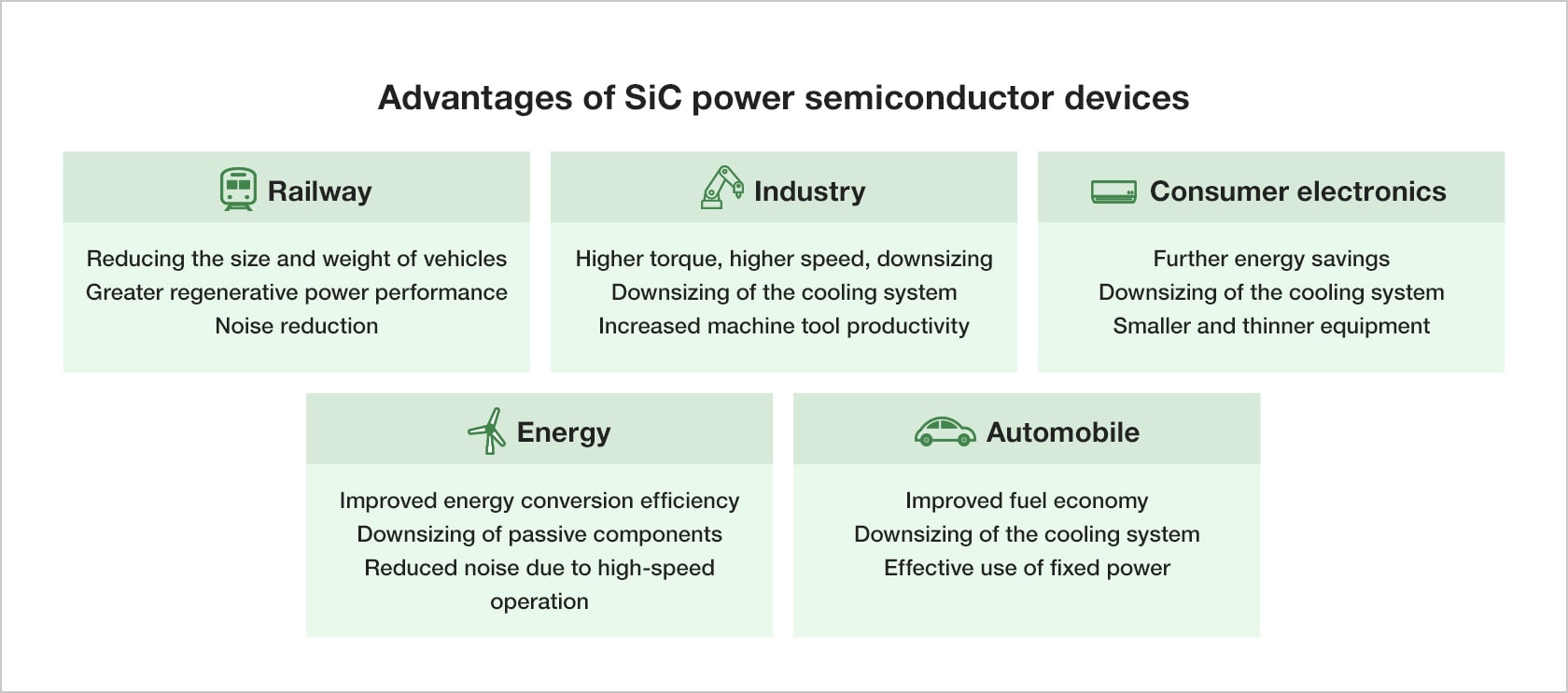

How do SiC power semiconductors affect the devices in which they are installed?

Noguchi: For example, if we change the material used for power semiconductors in hybrid and electric vehicles it is possible to dramatically improve the efficiency of the inverter that drives the motor. Not to mention, by utilizing battery energy efficiently, it is possible to increase vehicle mileage. Solar power generation efficiency can also be improved. The sunlight conditions to generate power via solar panels are constantly changing and at such times the power semiconductor switches on and off frequently to keep the output constant and store energy in a storage battery. If we use a SiC power semiconductor, output becomes smoother and, consequently, higher power generation efficiency is achieved.

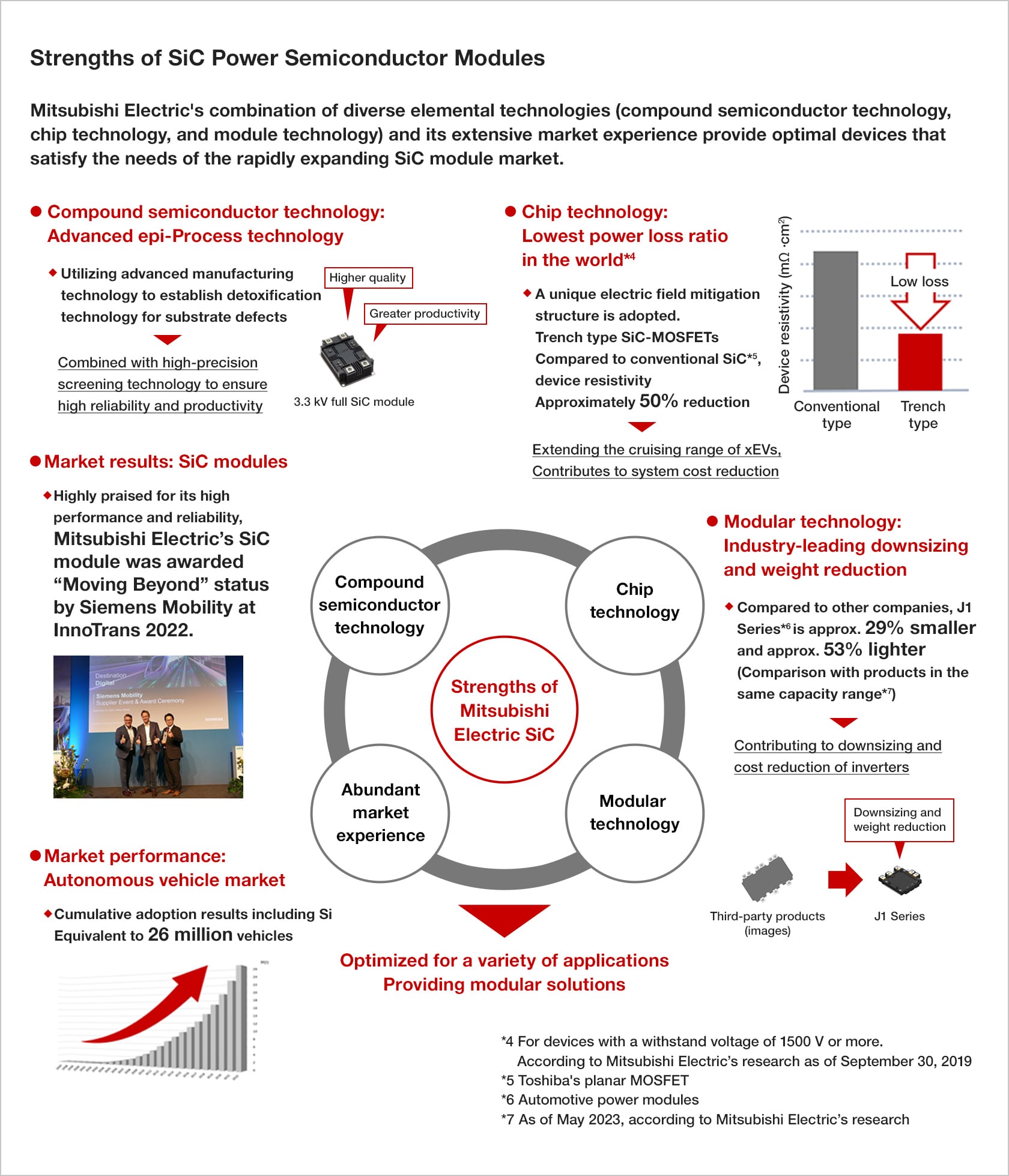

The strengths of Mitsubishi Electric's SiC power semiconductors include the essential compound semiconductor technology, chip technology, and module technology, as well as rich market achievement based on these technologies.

Mitsubishi Electric began developing SiC power semiconductors in the early 1990s. In 2010, the company released "Kirigamine," the world's first room air conditioning unit using a SiC power semiconductor. In 2015, it has also developed a main circuit system using the "full SiC power module*8" for the Tokaido bullet train line. It was the world's first run test using a full SiC power module, and in July 2020, the bullet train N700S commenced operation fitted with this module.

- *8A power semiconductor that uses SiC for both the transistor and diode parts.

Noguchi: Generally, compared to silicon, SiC's characteristics fluctuate quite significantly, including deterioration due to aging. However, Mitsubishi Electric's SiC power semiconductors not only offer minimal characteristic fluctuation but also have the best power loss ratio per semiconductor chip surface area in the world*9. For these reasons, we have earnt a trustworthy reputation among our customers, and our SiC power semiconductors are used in many settings, with a focus on railway vehicles.

- *9In elements with withstand voltage performance of 1500 V or higher; based on Mitsubishi Electric's research as of the PR announcement on September 30, 2019.

SiC power semiconductors promising to be a driving force for GX

In July 2022, the Green Transformation (GX) Implementation Council, chaired by Prime Minister Kishida, was formed, and in February 2011, the Cabinet approved the Basic Policy for GX Realization. GX represents a major shift from the fossil energy-centered industrial and social structure that has been mainstream since the Industrial Revolution to a clean energy-centered one. SiC power semiconductors are absolutely indispensable in order to achieve GX in a sustainable way. In addition, METI established new energy conservation standards for residential air conditioners in 2022, which call for up to 35% increase in energy consumption efficiency during cooling by 2027. For this reason, attention is bound to gather around SiC power semiconductors in this domain too.

Noguchi: Mitsubishi Electric has identified "carbon neutrality" as one of our five areas of sustainability management, and power semiconductors are key to achieving this goal. Our goal is to become the world's top power semiconductor manufacturer by the year 2030. To achieve this, we will improve the performance of our products and increase our production capacity by investing in sufficient equipment to ultimately help bring about a carbon-neutral society, and realize GX on a global scale.

*Information on products, services, and affiliations in this article is current at the time of the interview (December 2023).

Interview and text by Junko Ichihara