Initiatives that contribute to addressing social challenges

Automotive Equipment Group

Aiming to Achieve the SDGs through Development of Technologies and Corporate Activities that Contribute to the Decarbonization of the Automobile Industry and the Creation of a Safe and Secure Society

The Automotive Equipment Group aims to provide a range of equal opportunities to move safely and freely with low impact on the environment for all people, including the elderly, those with disabilities, and visitors from foreign countries, people who do not understand language, by providing electronic and electric device components. Through these efforts, we will contribute to realizing a sustainable society.

More efficient engines and electrification as seen in (P)HEVs*1 and EVs*2 are needed, in order to achieve low fuel consumption. Mitsubishi Electric enables low fuel consumption in vehicles, with various product to achieve high efficiency in engines, motors and inverters for electric vehicles, and more, and ultimately contribute to a decarbonized society.

As an example of efforts for decarbonization in the manufacturing processes of automotive equipment, we are reducing electricity usage by introducing high energy efficiency equipment, using waste heat for production equipment, and thoroughly implementing energy-saving technologies such as centralized monitoring and optimized control of air conditioning and ventilation equipment. Moreover, we are promoting energy generation, such as new installation and expansion of our own PV*3 and the introduction of PPA*4 models, and procurement of renewable energy in a planned manner to accelerate decarbonization. These activities are also being implemented at overseas manufacturing bases to accelerate our global decarbonization efforts.

- *1 (Plug-in) Hybrid Electric Vehicle

- *2 Electric Vehicle

- *3 Photovoltaic

- *4 Power Purchase Agreement

| Major social challenges for which risks and opportunities have been recognized and evaluated | Priority SDG initiatives |

|---|---|

|

|

Initiatives that contribute to addressing social challenges

Technological Innovation of Automotive Equipment Products for Autonomous Driving

Mitsubishi Electric is proceeding with the technological innovation of automotive equipment products with the aim of creating an eco-conscious, accident-free, comfortable urban space.

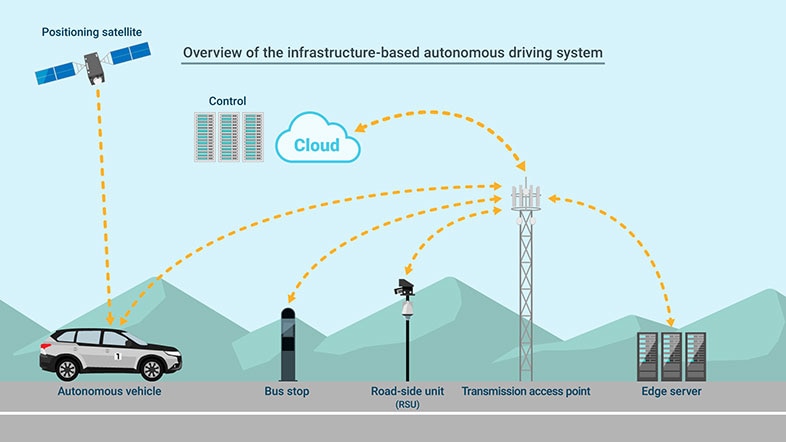

We have developed an autonomous driving system that combines "a self-driving technology" that uses peripheral-sensing technologies using millimeter-wave radars and cameras, and "an infrastructure cooperated technology" that uses a centimeter-level positioning reinforcement service signal from quasi-zenith satellites and high-accuracy 3D mapping. We have also developed autonomous driving technologies that enable driving on surface roads without high-definition maps and autonomous parking both indoors and outdoors. These technologies have been installed in a xAUTO test vehicle that is being used to conduct testing on highways and surface roads as a step towards the practical introduction of autonomous driving technologies that simultaneously enable high levels of safety and comfort.

-

Overview of the infrastructure-based autonomous driving system

-

xAUTO car equipped with autonomous driving technologies

As a result of recent various changes in lifestyle, there are ever-increasing expectations toward automated transport. To respond to such changes, we will implement the "last mile delivery mobility service" in indoor robots for hospitals and general-purpose delivery robots that can travel outdoors as well. We will provide the best solutions for society together with companies that use autonomous robots and startup companies with advanced technologies.

-

Autonomous delivery robot for multi-purpose

-

Examples of removable carts (reference images)

(Left: chemical tray delivery cart for hospitals; right: product delivery cart for commercial facilities)

- Sustainability

- Management message

- Sustainability management

- Initiatives that contribute to addressing social challenges

- Public utility systems group

- Energy & industrial systems group

- Building systems group

- Defense & space systems group

- Living environment & digital media equipment group

- Factory automation systems group

- Automotive equipment group

- Semiconductor & device group

- IT solution business & business process reengineering group

- Initiatives to create value

- Materiality

- Initiatives to address the SDGs

- Initiatives that contribute to addressing social challenges

- Environment

- Social

- Philanthropic activities

- Governance

- Policy on sustainability information disclosure

- Guideline comparison tables

- Reports